In-place auxiliary device for switch cabinet

A technology for auxiliary devices and switch cabinets, applied in switchgear, substation/switch layout details, electrical components, etc., can solve problems such as endangering personal and equipment safety, irregular operation behavior, and low work efficiency, so as to reduce the number of people and process Easy to make, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

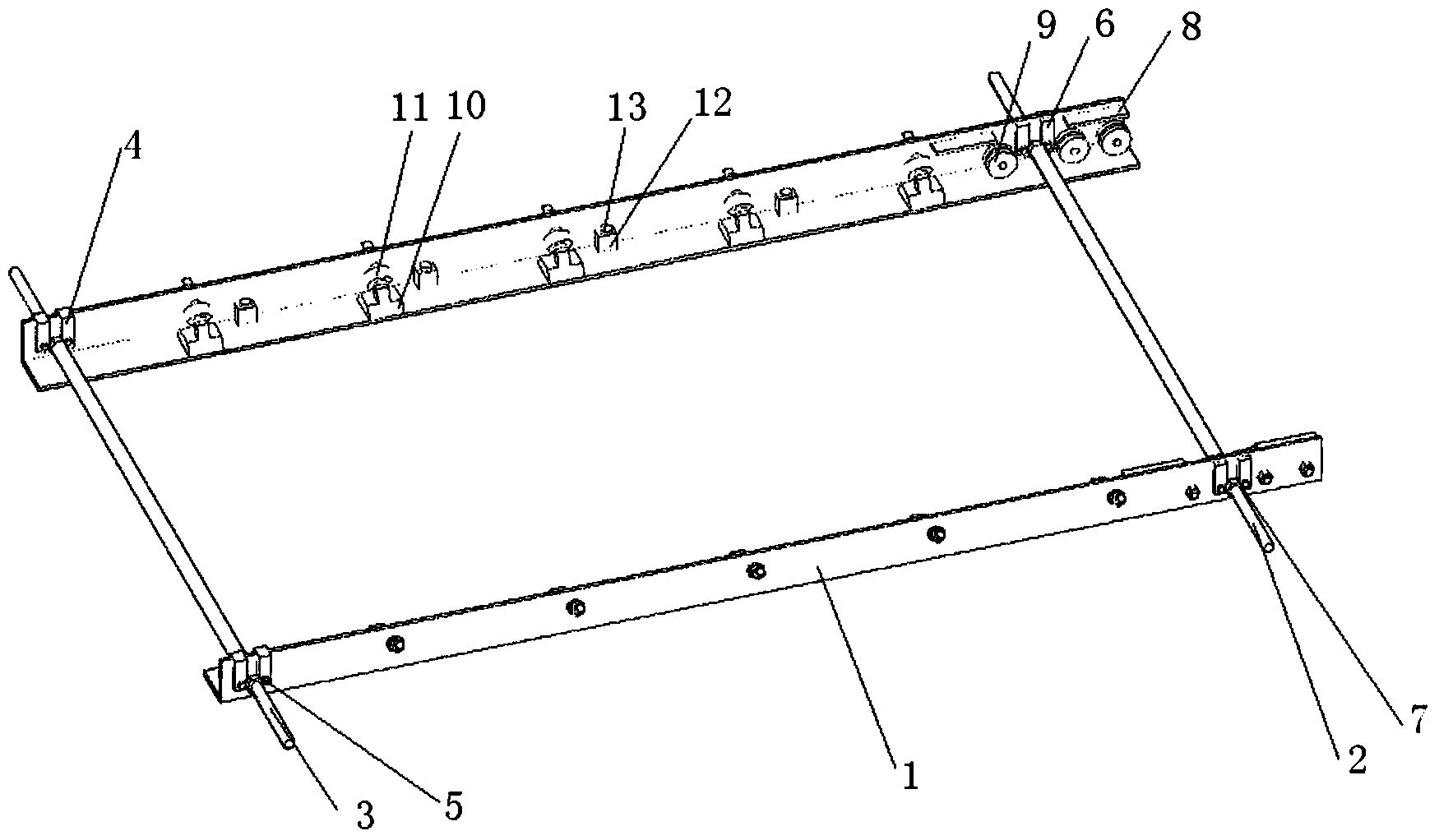

[0013] Such as figure 1 As shown, the present invention mainly includes two symmetrically arranged rails 1. The front ends of the two rails 1 are connected by a front disengagement rod 2, and a front nut bayonet 6 is provided at the connection between the two rails 1 and the front disengagement rod 2. , The front nut bayonet 6 is clamped with the front disengagement nut 7, and the front disengagement nut 7 is threadedly connected with the front disengagement rod 2. When the front disengagement lever 2 is turned, the front disengagement nut 7 can drive the two rails 1 to shrink inwardly, so as to narrow the distance between the two rails 1; when the front disengagement lever 2 is turned in the other direction, the front disengagement nut 7 7 can drive the two tracks 1 to expand outward, so as to increase the distance between the two tracks 1 .

[0014...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com