Multilayer circuit board and method for manufacturing same

A multi-layer circuit board and outer layer technology, which is applied in the direction of multi-layer circuit manufacturing, printed circuit components, electrical connection printed components, etc., can solve the problem of increasing the production cost of multi-layer circuit boards, high price, damage to multi-layer circuit boards, etc. problem, to achieve the effect of reducing test cost and detection cost, and simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The multilayer circuit board provided by the technical solution and its manufacturing method will be further described in detail below in conjunction with the drawings and embodiments.

[0023] The manufacturing method of the multilayer circuit board provided by the embodiment of the technical solution includes the following steps:

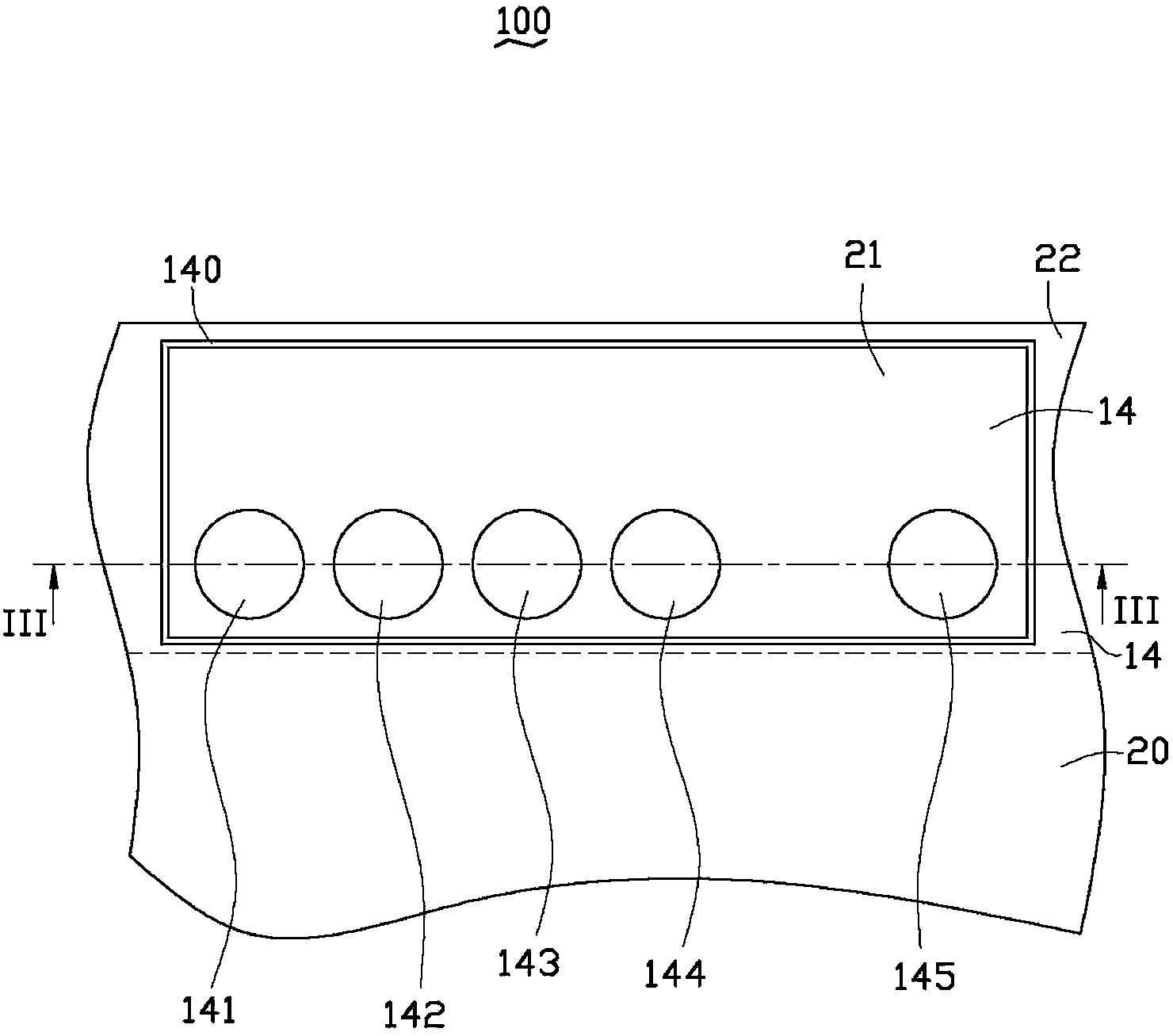

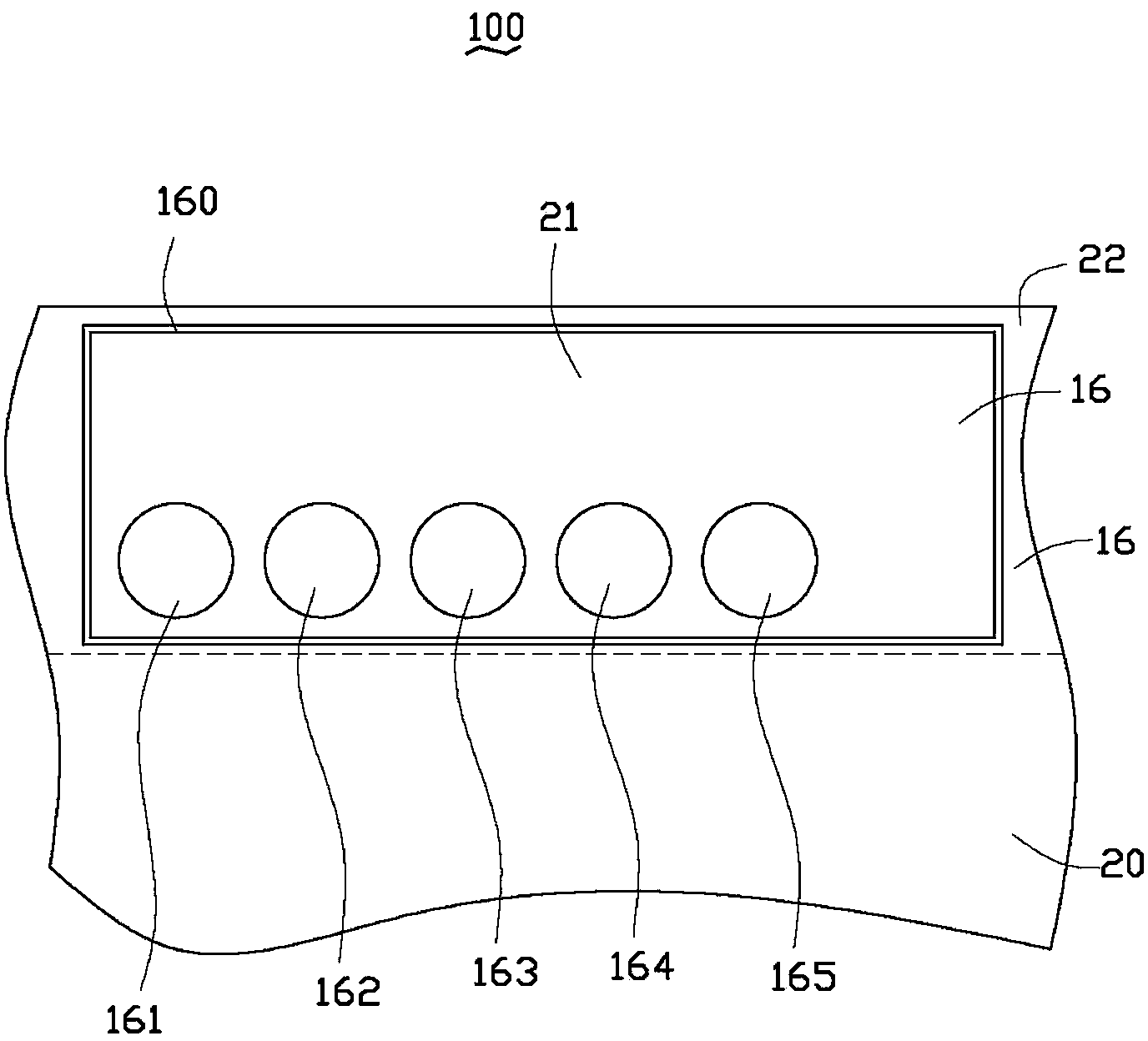

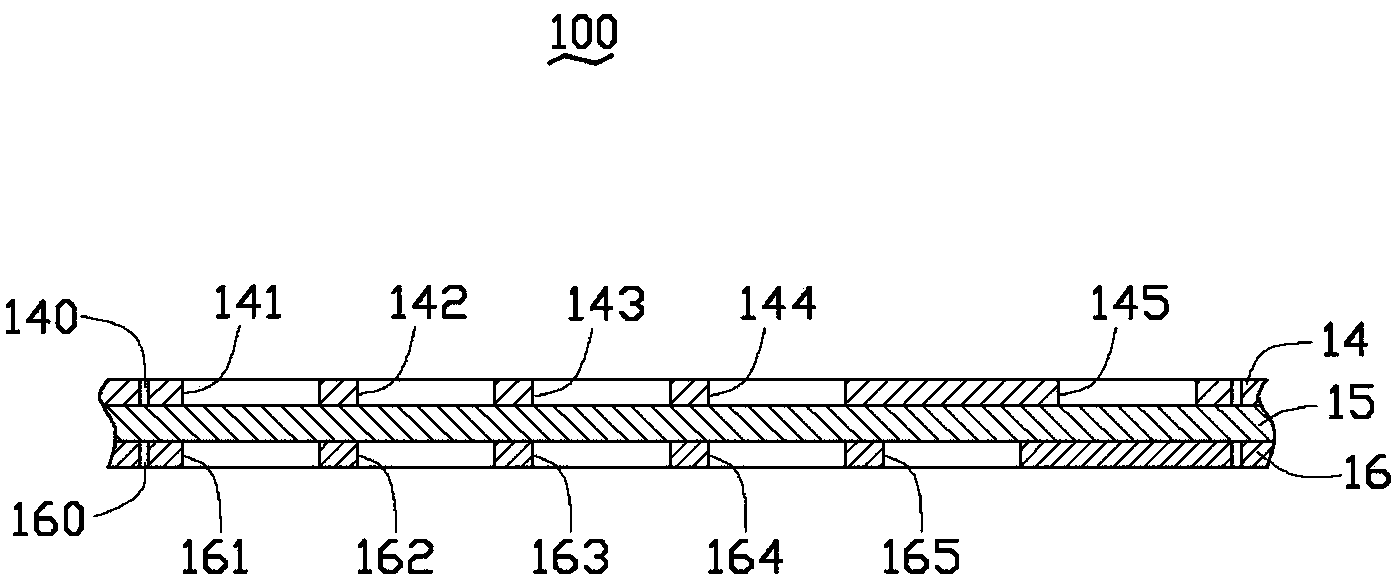

[0024] For a first step, see Figure 1-3 , providing an inner core board 100 .

[0025] In this embodiment, a two-layer inner core board 100 is taken as an example for illustration. The inner core board 100 includes a first inner conductive circuit layer 14 , a second insulating layer 15 and a second inner conductive circuit layer 16 stacked in sequence.

[0026] The inner core board 100 is formed with a product part 20 and a non-product part 22 other than the product part 20. The non-product part 22 includes a test area 21. In this embodiment, the test area 21 is located in the inner The board edge position of the layer core board 100. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com