Method for detecting stability of phenolic substance on friction interface

A technology of phenolic substances and detection methods, which is applied in the field of detection of phenolic substances on the stability of friction interfaces, can solve the problems of cumbersome operation, high requirements for experimenters, and high testing costs, and achieve simple testing equipment, simple and fast operation, Effective identification of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of phenolic lubricating oil samples

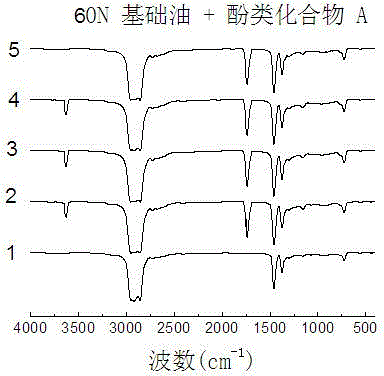

[0025] Weigh 0.5022g of phenolic substance A, 99.5175g of Ssangyong 60N base oil, add phenol A into a beaker with base oil, put it into an ultrasonic machine and ultrasonically disperse for 1 hour. Precipitation, no precipitation indicates that the sample preparation is complete.

[0026] 2. Stability test of phenolic substances on the friction interface

[0027] Friction and wear tester: choose bearing steel as the friction pair, use steel balls for friction experiment, load 5N, laps 6000 Laps, drop oil sample on the friction pair, carry out wear test under normal temperature and pressure, and conduct infrared spectrum test after the experiment .

[0028] Four-ball friction testing machine: the friction pair is a bearing steel ball with a diameter of 12.7mm, the wear time is 60min, the load is 40N, the temperature is 75°C, the transmission is 1200r / min, and the pressure is normal. The oil sample is added to the bea...

Embodiment 2

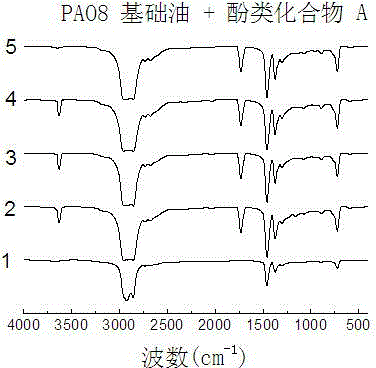

[0031] 1. Preparation of phenolic lubricating oil samples

[0032] Weigh 0.5025g of phenolic substance A, 99.5167g of Ssangyong 60N base oil, add phenol A into a beaker with base oil, put it into an ultrasonic machine and ultrasonically disperse for 1 hour. Precipitation, no precipitation indicates that the sample preparation is complete.

[0033] 2. Stability test of phenolic substances on the friction interface

[0034] Friction and wear tester: choose bearing steel as the friction pair, use steel balls for friction experiment, load 5N, laps 6000 Laps, drop oil sample on the friction pair, carry out wear test under normal temperature and pressure, and conduct infrared spectrum test after the experiment .

[0035] Four-ball friction testing machine: the friction pair is a bearing steel ball with a diameter of 12.7mm, the wear time is 60min, the load is 40N, the transmission is 1200r / min, the temperature is 75°C, normal pressure, the oil sample is added to the beaker, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com