Asphalt mixture static modulus testing method

A technology of asphalt mixture and static modulus, applied in the direction of applying stable tension/pressure to test material strength, etc., can solve the problem of high requirements for test equipment, unfavorable test method promotion, and lack of good simulation of asphalt mixture stress Status and other issues, to achieve the effect of simple operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

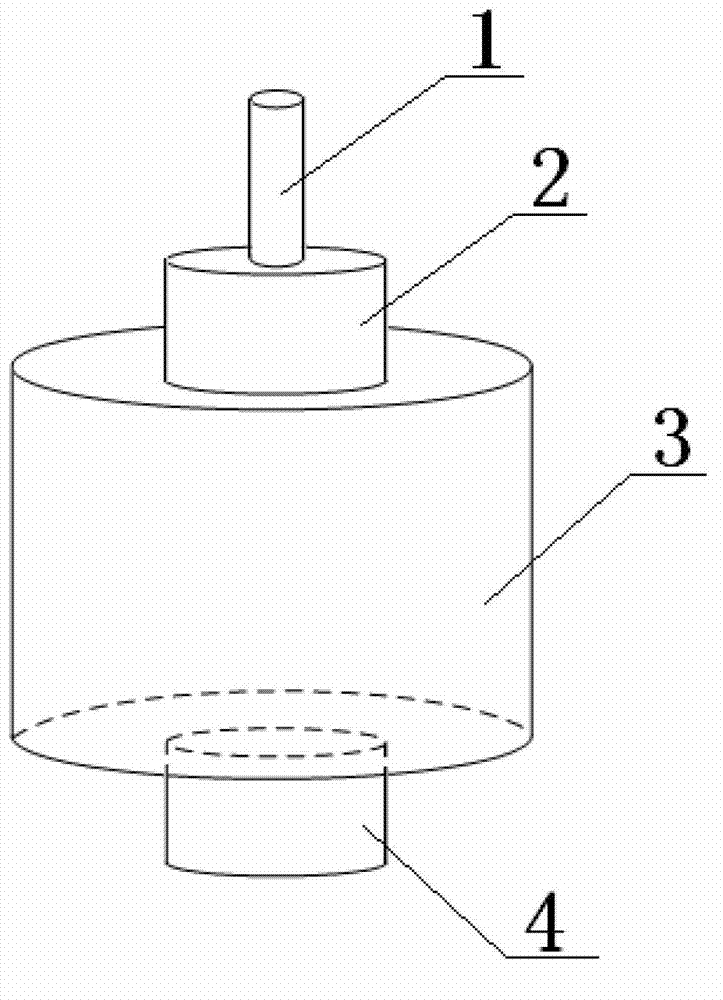

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] A method for testing the static modulus of an asphalt mixture comprises the following steps.

[0024] (1) Prepare a cylindrical specimen of asphalt mixture and two steel indenters.

[0025] The cylindrical specimens were prepared in the following way: first, according to the gradation and asphalt-stone ratio of the asphalt mixture to be evaluated, four asphalt mixture specimens were formed by using the asphalt mixture rotary compactor, and the porosity of the asphalt mixture specimens was 4%; then cut the asphalt mixture test piece into a cylindrical test piece with a diameter of 150mm and a height of 80mm; Measure the height of the cylindrical specimen in four symmetrical directions. If the height difference between any two sides is greater than 2mm, the specimen will be discarded.

[0026] Both steel indenters are of cylindrical structure with a diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com