LED off-line chip mounter

An off-line, placement machine technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of inaccurate mobile positioning, slow feeding speed, inaccurate displacement of the placement head, etc., to improve the placement yield rate , Improving placement accuracy, not easy to move and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

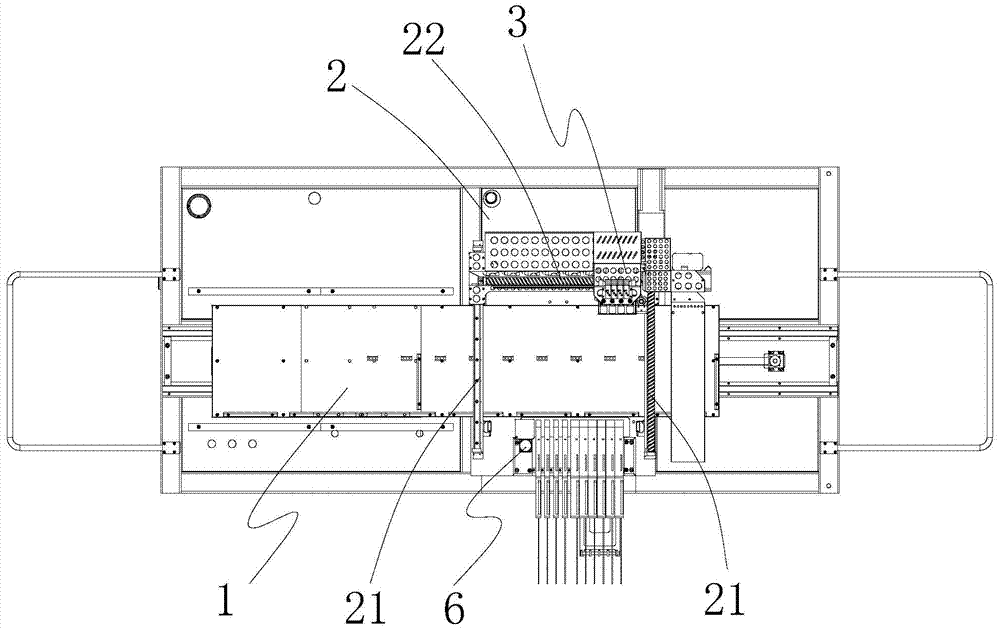

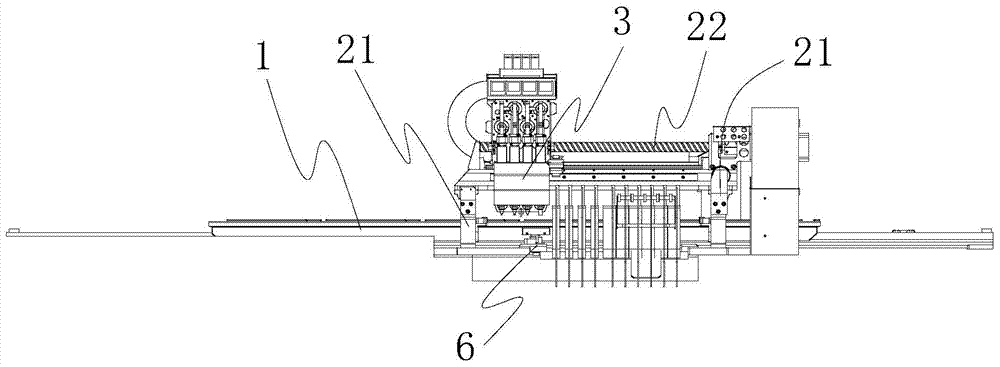

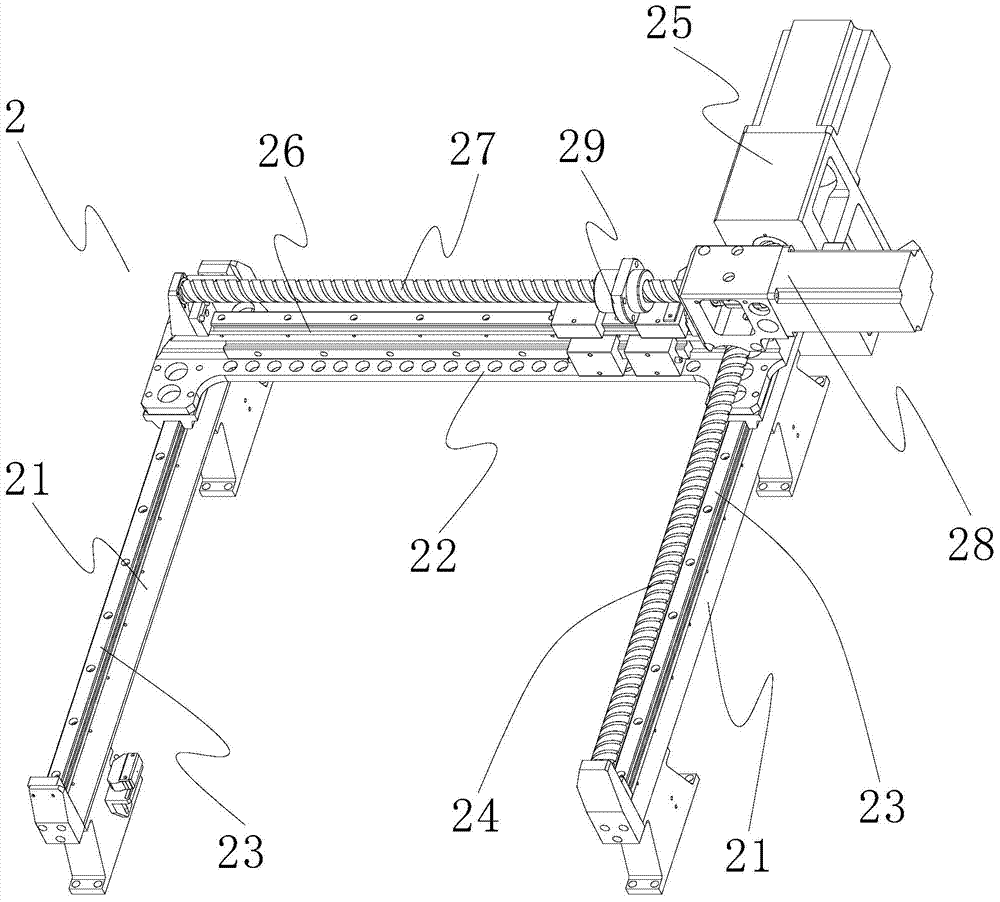

[0022] Such as figure 1 with figure 2 shown (where, figure 1 The direction shown in is the viewing direction of the top view. figure 2 The direction shown is the viewing angle of the front view), the LED off-line placement machine of the present invention includes a feeding track 1, an X-Y moving platform 2, a placement head 3, an industrial computer (not shown in the figure), a display 7 and an input equipment8. The feeding track 1 is driven by the P-axis motor 59, so that the feeding track 1 is driven along the figure 1 Move in the left and right directions. Described X-Y mobile platform 2 comprises two Y-axis frames 21 that are arranged in parallel and the X-axis frame 22 that can move along the length direction of Y-axis frame 21, and the length direction of X-axis frame 22 is perpendicular to Y-axis frame 21 in the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com