Mechanism and chair for powered combined and independent seat back and leg rest motion

A power-driven, independent motion technology, used in chairs, reclining chairs, other seating furniture, etc., to solve the problem of inability to operate footrests and backrests independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will now be described in more detail with reference to the accompanying drawings.

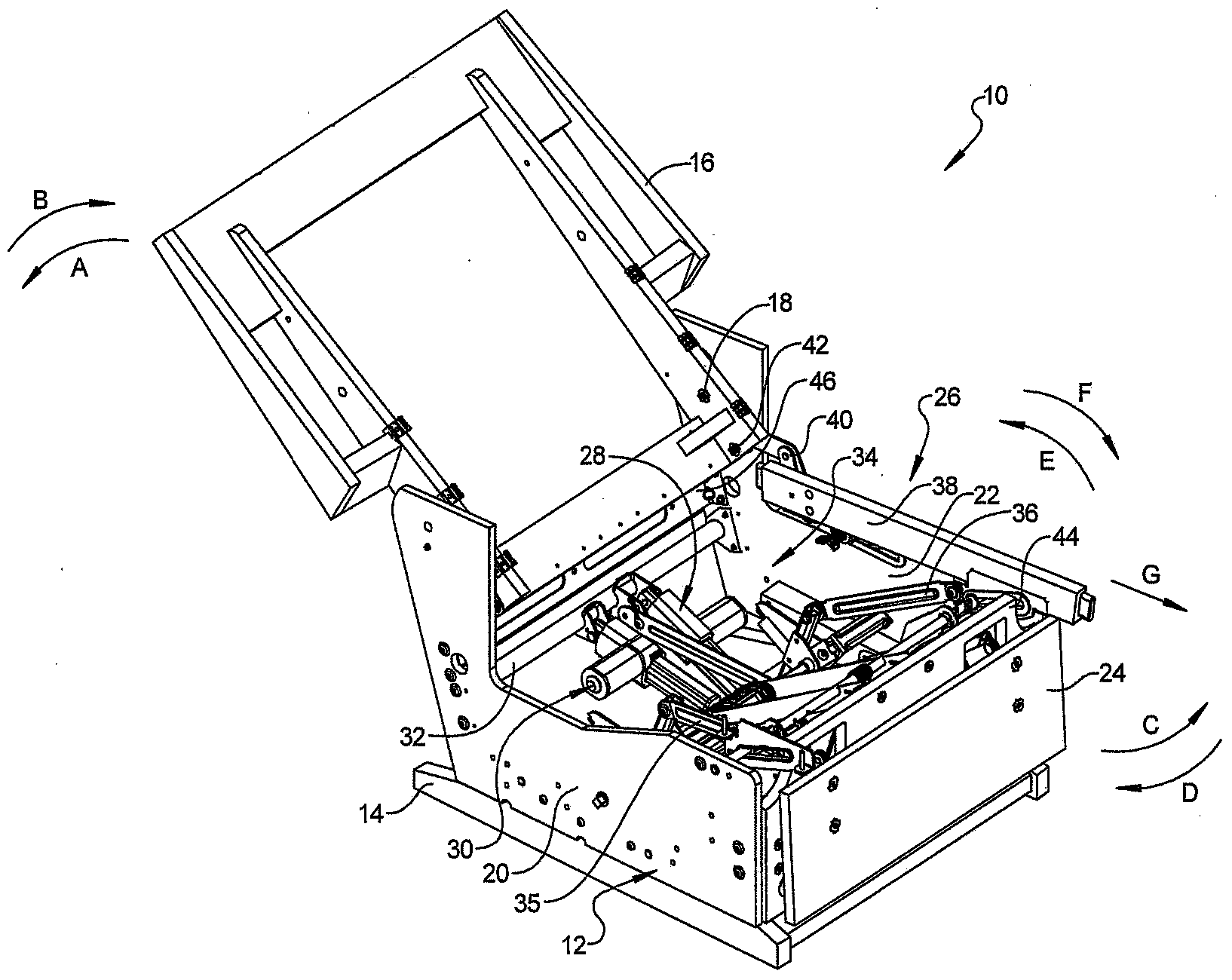

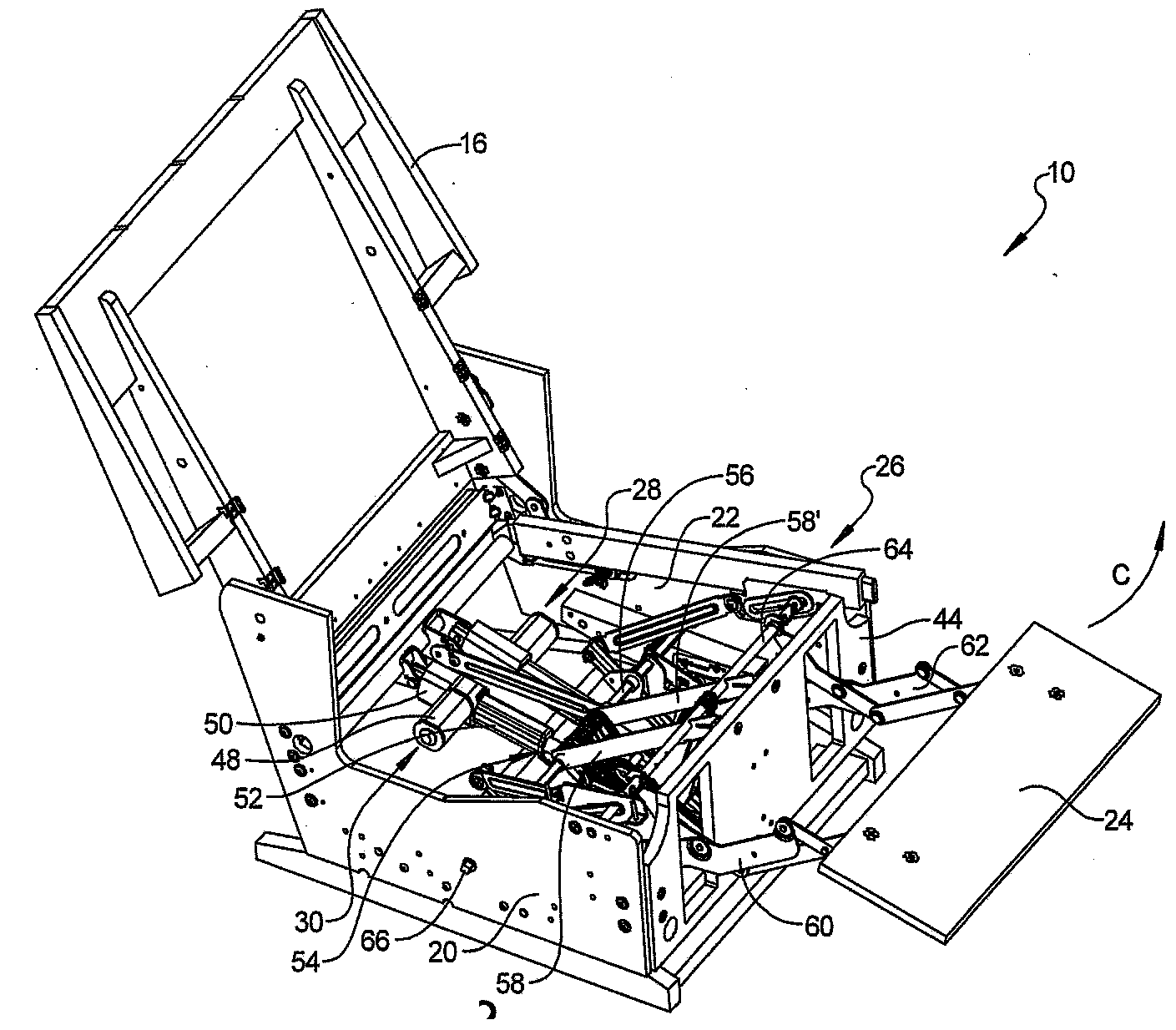

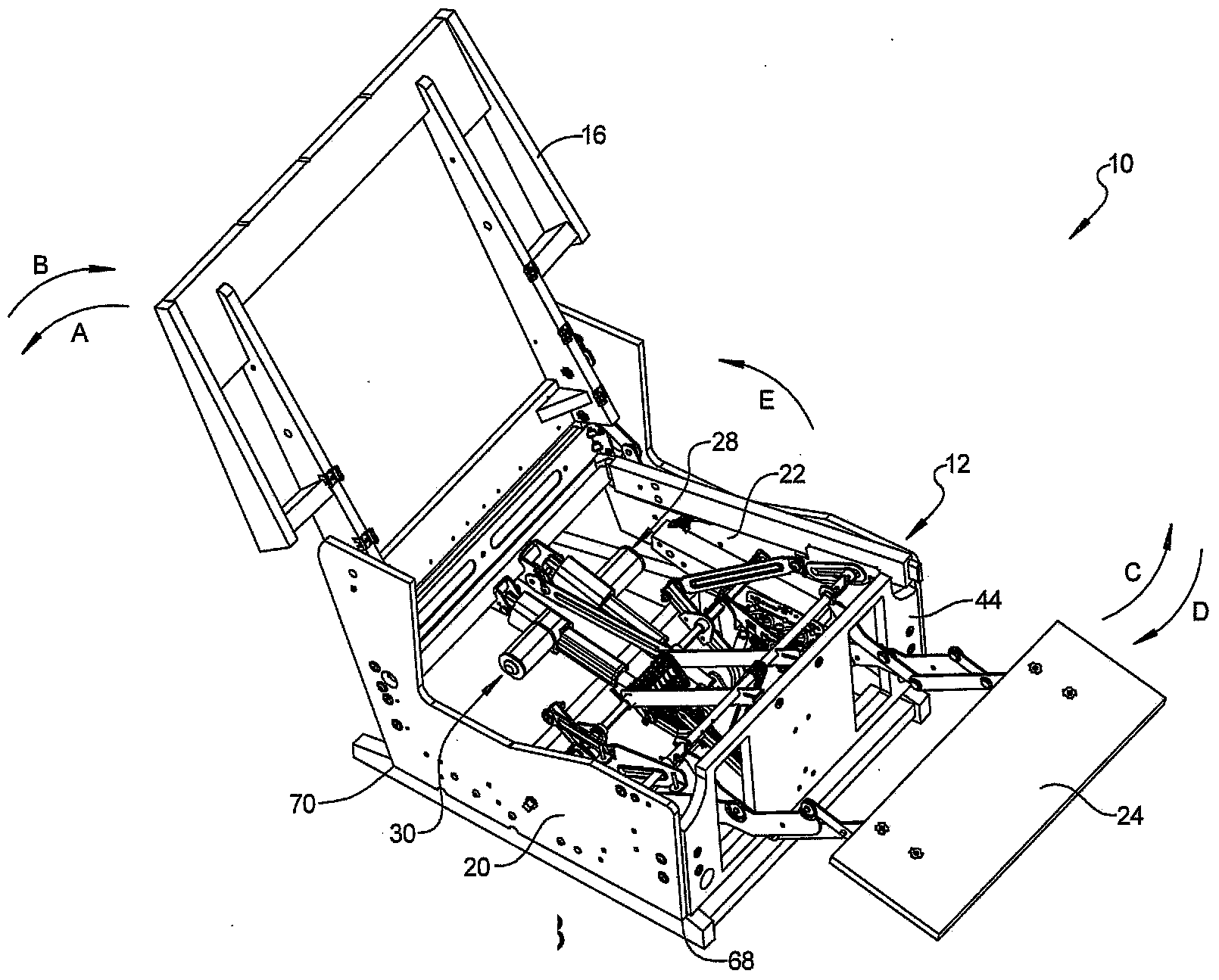

[0032] Such as figure 1 As shown, the furniture 10 includes a furniture support assembly 12 rotatably supported on a base 14 . The backrest 16 is rotatably connected to the furniture support assembly 12, and can rotate from the fully upright position toward the direction A of lying on the back, or return to the fully upright position from the fully lying position toward the returning direction B of the backrest, or Any position between a fully upright position and a fully reclined position. The back rest 16 is passed through the swivel connectors 18 opposite to each other (only one of which can be clearly seen in figure 1 ) is rotatably connected to the furniture support assembly 12. The furniture stand assembly 12 includes a first side member 20 and a second side member 22 for a user seated on the furniture 10 . The first side member 20 is on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap