Turbine housing and exhaust gas turbine supercharger

A technology of turbine casing and turbine impeller, which is applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

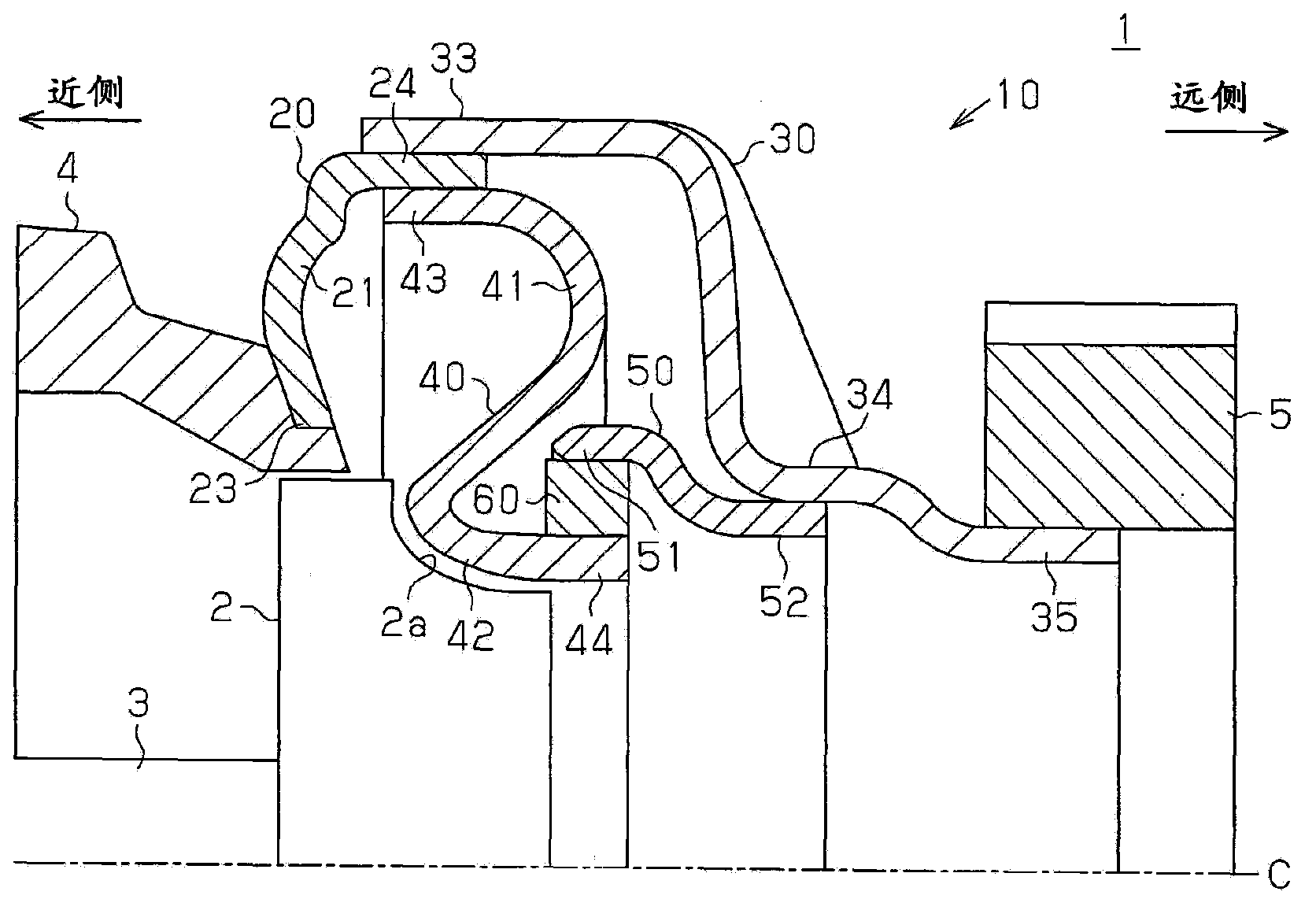

[0039] will refer to Figure 1 to Figure 4 A turbine housing and an exhaust turbocharger according to one embodiment of the present invention are described.

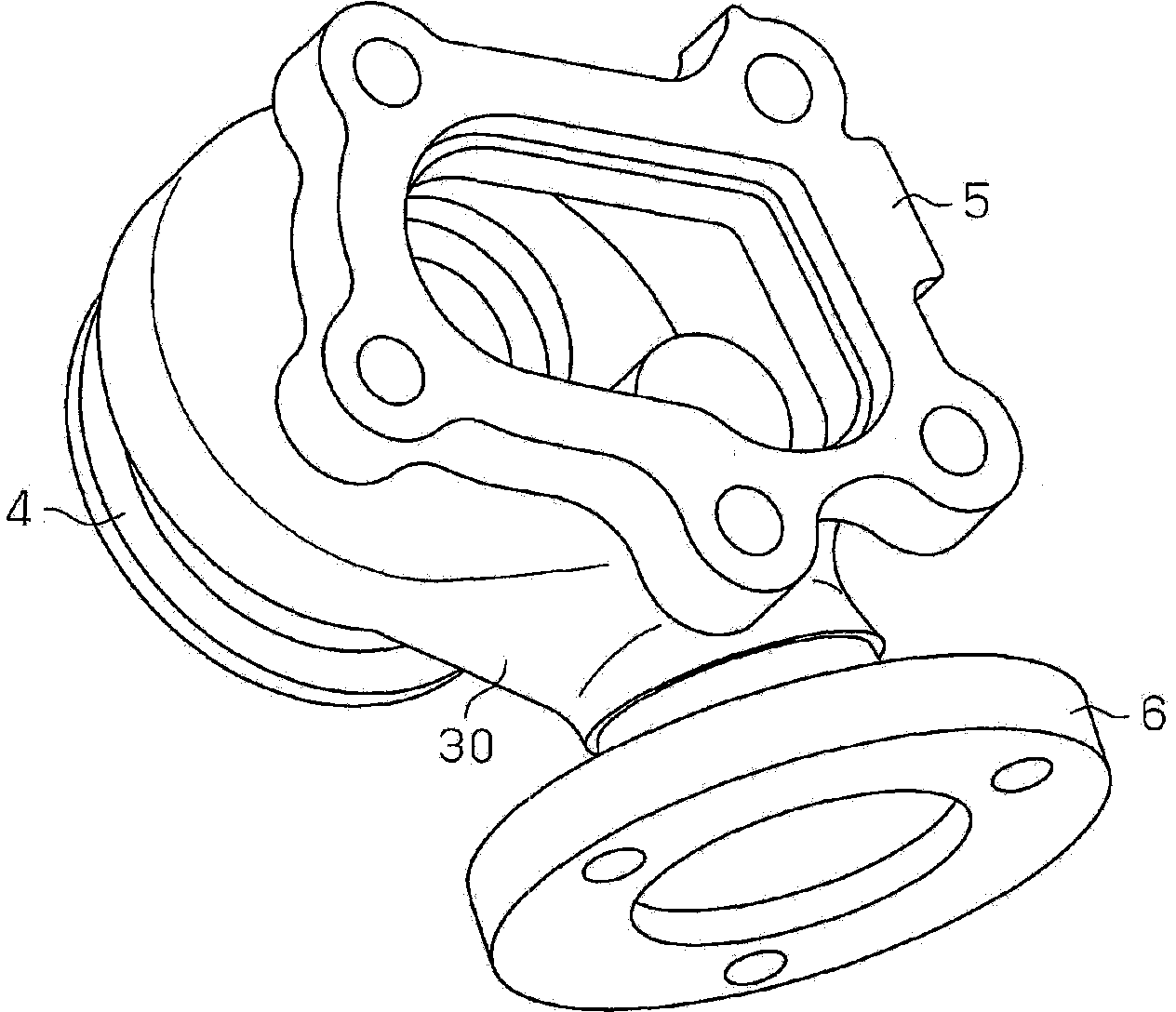

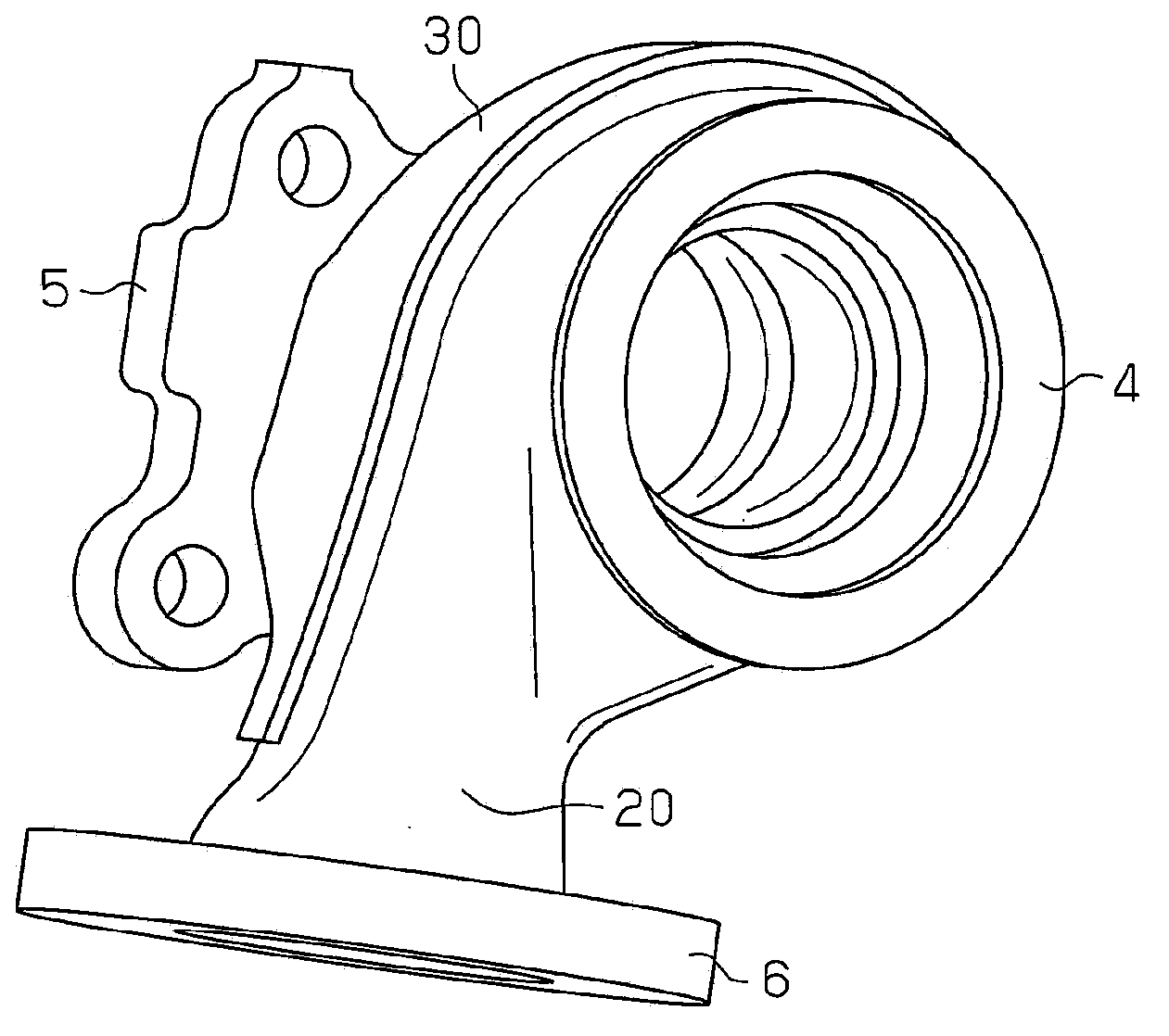

[0040] figure 1 A partial cross-sectional structure of the exhaust turbocharger 1 in this embodiment is shown. figure 2 The three-dimensional structure of the turbine housing 10 viewed from the side corresponding to the distal flange 5 is shown. image 3 The three-dimensional structure of the turbine housing 10 viewed from the side corresponding to the proximal flange 4 is shown.

[0041] In the following description, the side close to the turbine shaft 3 along the axial direction C of the turbine wheel 2 ( figure 1 The left side in ) is called the proximal side, while the side that will be away from the turbine axis 3 ( figure 1 The right side) is called the far side.

[0042] Such as Figure 1 to Figure 3 As shown in , the exhaust turbocharger 1 includes a turbine shaft 3, a turbine wheel 2 and a turbine housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com