Ultrasound measurement assembly for multidirectional measurement

A technology of ultrasonic measurement and components, applied in the direction of measuring devices, radio wave measurement systems, using re-radiation, etc., to achieve the effect of reduced delay and high angular resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

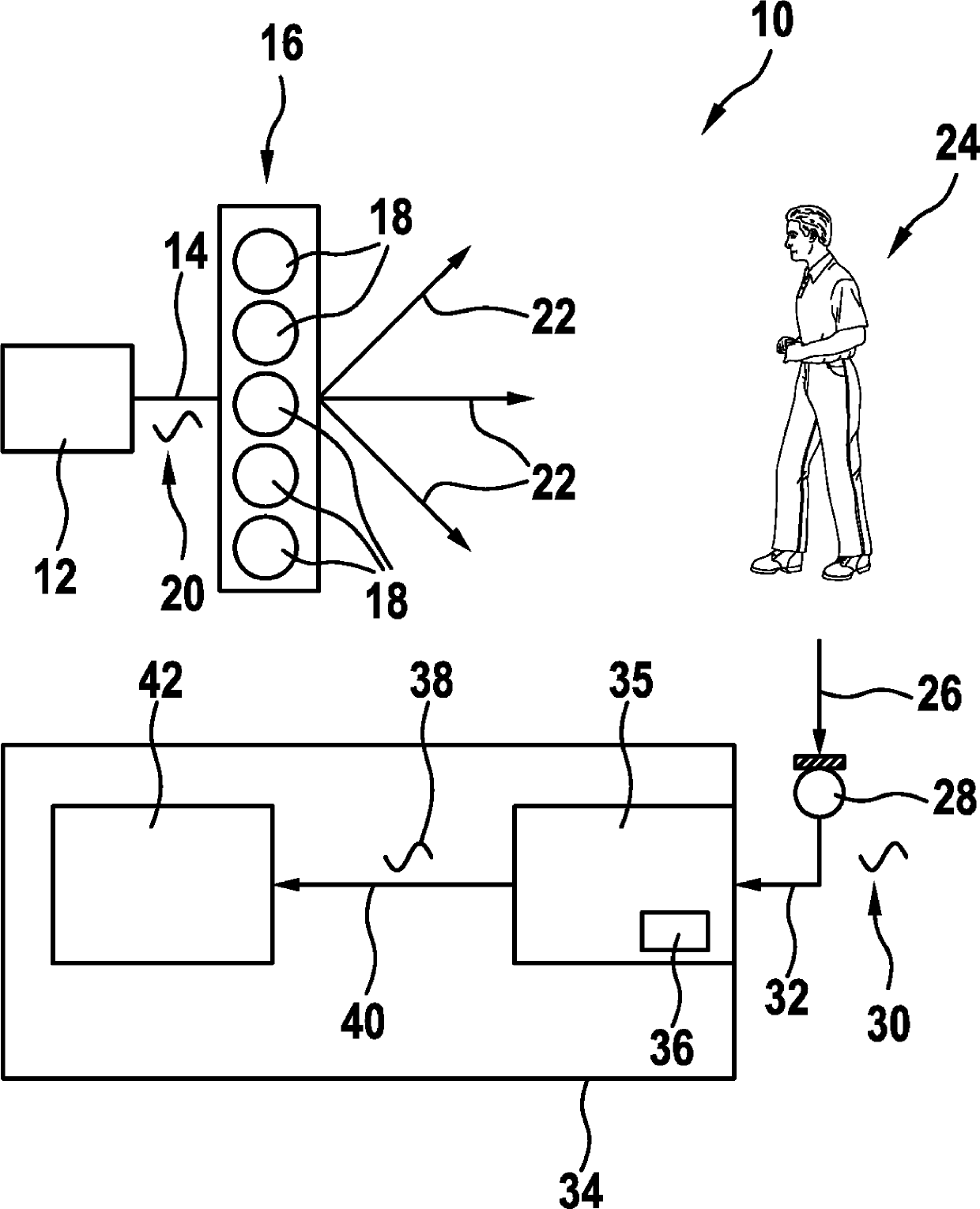

[0039] figure 1 The ultrasound measurement assembly 10 is shown schematically. It comprises a drive unit 12 connected via lines 14 to an array 16 of ultrasound transmitter elements 18 forming an ultrasound transducer. The drive unit 12 is generating a drive signal 20 which is transmitted via the line 14 to the array of ultrasound transmitter elements 16 . The ultrasound transmitter elements 18 are driven by drive signals 20 , wherein they generate ultrasound beams directed in multiple directions 22 simultaneously. The ultrasonic beam includes a plurality of ultrasonic waves of different wavelengths corresponding to the driving frequency of the driving signal 20 . As will be explained exemplarily later, the different waves spread into different directions 22 depending on the ratio between the wavelength and the dimension of each ultrasound transmitter element 18 . Thus, in different spatial directions 22 ultrasound waves of different frequency spectrums are emitted.

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com