Manual tin soldering table for circuit board

A circuit board and manual soldering technology, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of wasting manpower, low welding efficiency, chemical flux fumes, etc., and achieves simple structure, convenient operation, and guaranteed welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

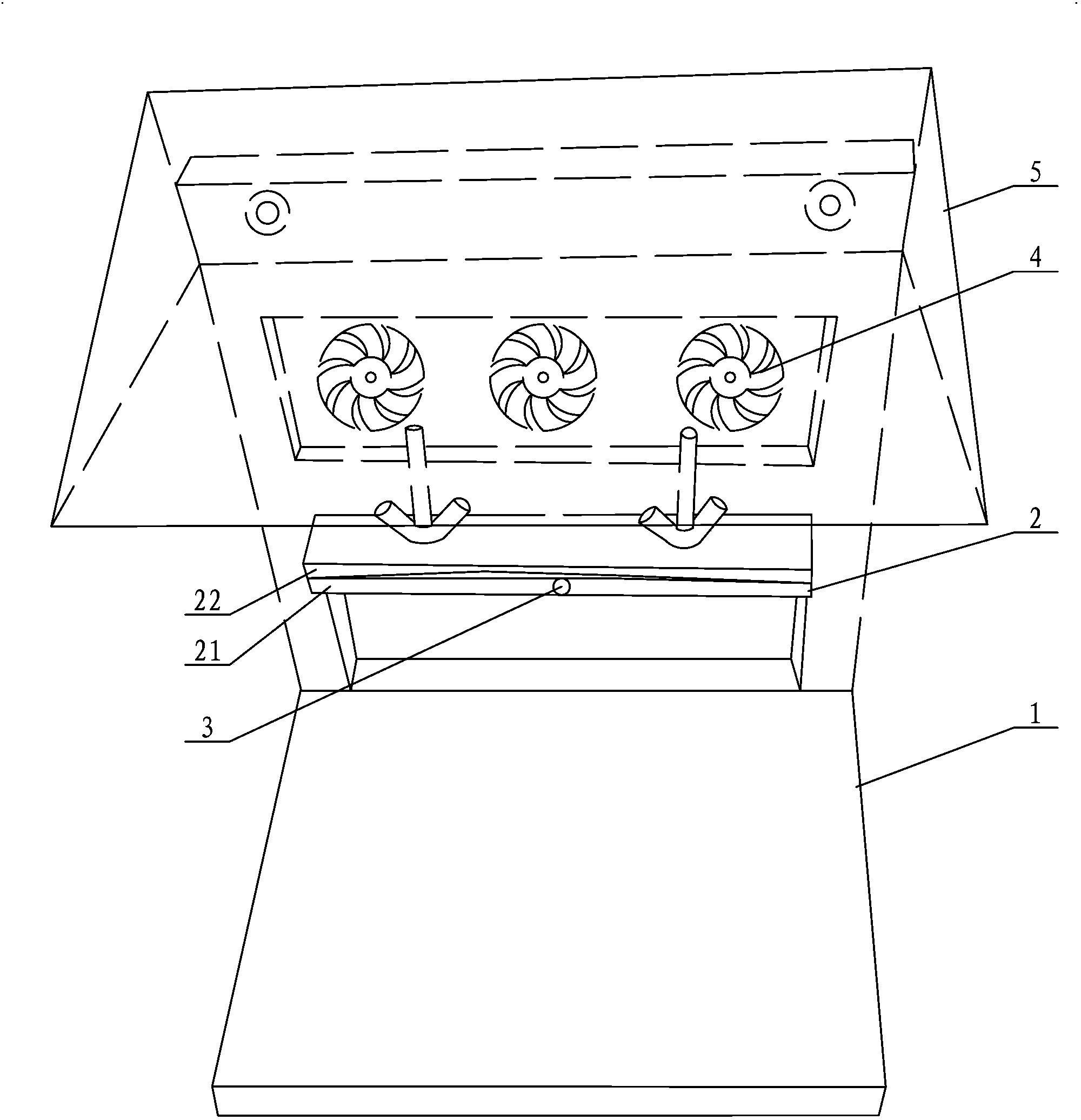

[0013] Such as figure 1 In the shown embodiment, the circuit board manual soldering station according to the present invention includes a tin station 1, on which a clamping platform 2 for fixing the circuit board is arranged, and the clamping platform 2 includes a bottom plate 21, and the bottom plate 21 is connected with the rotating shaft 3. The tin table 1 is connected so that the clamping platform 2 can be turned freely around the rotating shaft 3. The upper part of the bottom plate 21 is connected to the pressure plate 22 by bolts. Magnet b, and the magnetic poles of the contact ends of magnet a and magnet b are opposite poles, above the clamping platform 2, and on the tin platform 1, a fan 4 for air extraction is set, and a smoke baffle 5 is set above the fan 4, and The baffle plate 5 is made of plexiglass, and the baffle plate 5 is fixed on the tin platform 1 by bolts.

[0014] Before welding, clamp the circuit board between the bottom plate 21 and the pressure plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com