Membrane sewage filtration system

A filter system and sewage technology, applied in the direction of centrifugal separation water/sewage treatment, osmosis/dialysis water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve the erosion of filter membrane, poor drainage, weakened filtration efficiency, etc. problems, to achieve high filtration efficiency, high osmotic water pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

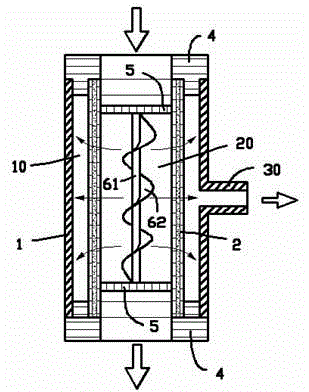

[0016] figure 1 Shown is the first embodiment of the membrane sewage filtration system, wherein the membrane sewage filtration system includes an outer pipe body 1 and an inner pipe body 2; a tube is formed between the outer pipe body 1 and the inner pipe body 2 type water purification chamber 10; the inside of the inner pipe body 2 is a cylindrical sewage chamber 20; both ends of the water purification chamber 10 are blocked by closing plugs 4; 30; both ends of the sewage chamber 20 are connected to a sewage circulation system with a circulation pump.

[0017] The sewage circulating flow system is mainly composed of a sewage source, such as a sewage tank, and a circulation pipeline. The circulation pipeline connects the sewage source, the inner pipe body 2, and the circulation pump into a circulation loop, so that the sewage circulates continuously in the loop .

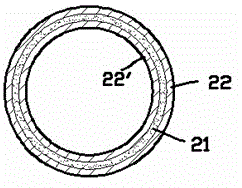

[0018] The outer pipe body 1 is made of impermeable material; the inner pipe body 2 is as figure 2 As shown, ...

Embodiment 2

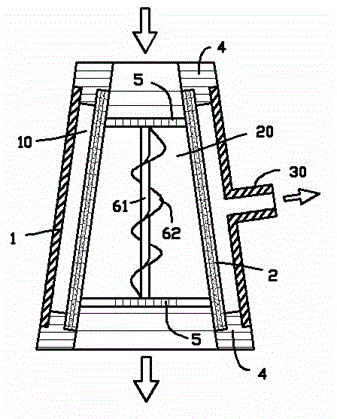

[0023] image 3 Shown is the second embodiment of the membrane sewage filtration system, which is different from the first embodiment in that: the diameter of the nozzle of the inner pipe body 2 near the water inlet end is smaller than the nozzle diameter of the water outlet end, so that the The sewage in the sewage chamber 20 gradually decelerates during the flow process, so that when the fluid just enters the inner pipe body 2, it has greater kinetic energy to drive the hydraulic drive components to rotate, so that the rotation speed of the water body itself is also rapidly increased , so that as soon as the sewage enters the sewage cavity 20, the fine separation of the particles and the water body can be obtained quickly, and the pressure on the surface of the filter membrane along the axial direction of the inner pipe body can be evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com