Diesel particulate filter provided with three-way catalytic coatings

A particle filter, catalytic coating technology, used in engine components, machines/engines, electrical controls, etc., to solve problems such as increased NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

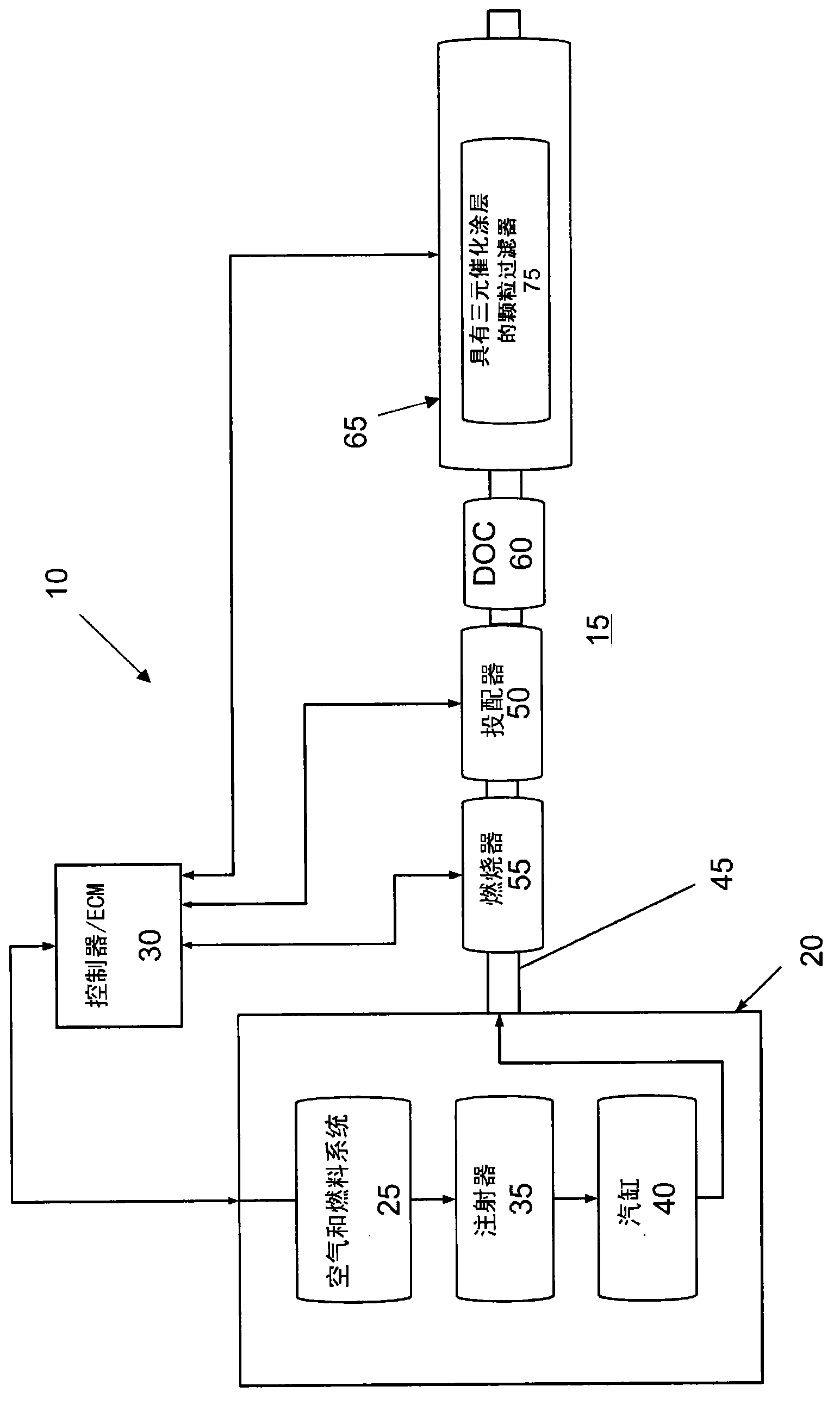

[0008] figure 1 A diesel engine system 10 is shown having an aftertreatment exhaust system 15 and a diesel engine body 20 . The diesel engine body 20 is configured to combust fuel to drive the system 10 . To this end, the diesel body 20 includes an air / fuel system 25 controlled by a controller / ECM 30 . The ECM 30 controls the air-fuel ratio of combustion in the cylinder 40 . The air-fuel ratio may be the stoichiometric air-fuel ratio or a lower air-fuel ratio when the diesel engine body 20 is running in a steady state. However, in transient operation, the air-fuel ratio is controlled such that it provides more mixture to the spark plug 35 to increase the power produced by the diesel engine body 20 in response to the transient condition.

[0009] The cylinders 40 provide diesel exhaust to the aftertreatment exhaust system 15 via, for example, a conduit, such as a conduit 45 . This diesel exhaust stream has many pollutants, including NO x . In other installations, the afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com