Fan main shaft calibration device

A technology for calibrating device and main shaft, applied in mechanical equipment, machine/engine, pump control and other directions, can solve the problems of large volume and weight of fan main shaft, high labor intensity of staff, inconvenient handling and fixing, etc., to improve detection efficiency and accuracy, reduce labor intensity of workers, and speed up production progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

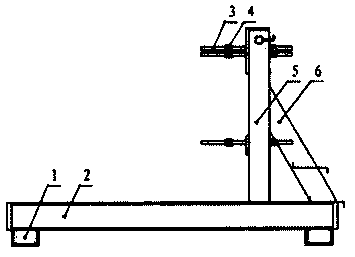

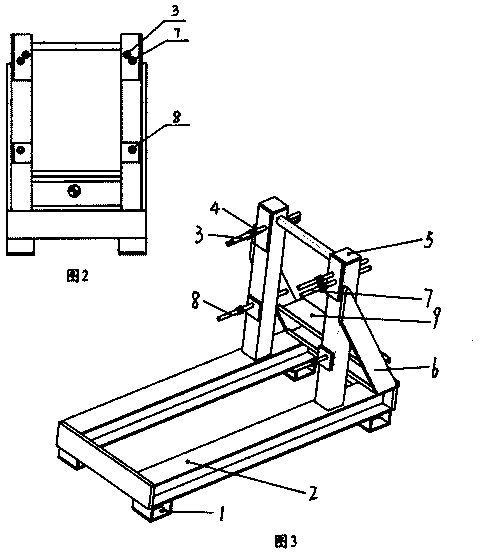

[0018] A fan shaft calibration device, comprising a base 2, a support column 5 and a positioning calibration rod, a plurality of legs 1 are installed on the lower surface of the base, two support columns are vertically installed side by side on the upper end surface of the base, each support column A rib 6 is installed between the outer side wall and the base, the two ribs are all positioned at the back of the support column, and a group of anti-slip pedals 9 are installed between the two ribs.

[0019] All wear a set of positioning and calibration rods on each support column, and the coaxial sleeve calibration nut 4 is positioned on the positioning calibration rod on the front of the support column, and there are two nuts. The top of each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com