Automatic separating and feeding device for steaming trays and control method of automatic separating and feeding device

An automatic separation and control method technology, applied in the directions of transportation and packaging, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low operating efficiency, high labor intensity, long waiting time for refueling, etc., and achieve reduction The effect of manual participation, reduction of labor costs, and improvement of industrial automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

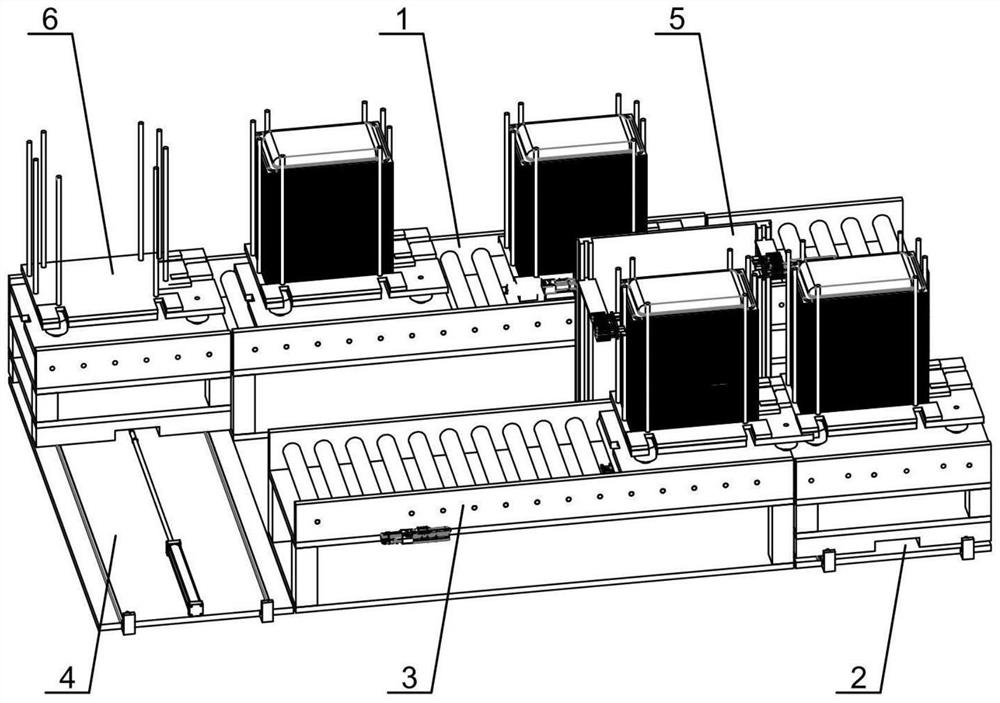

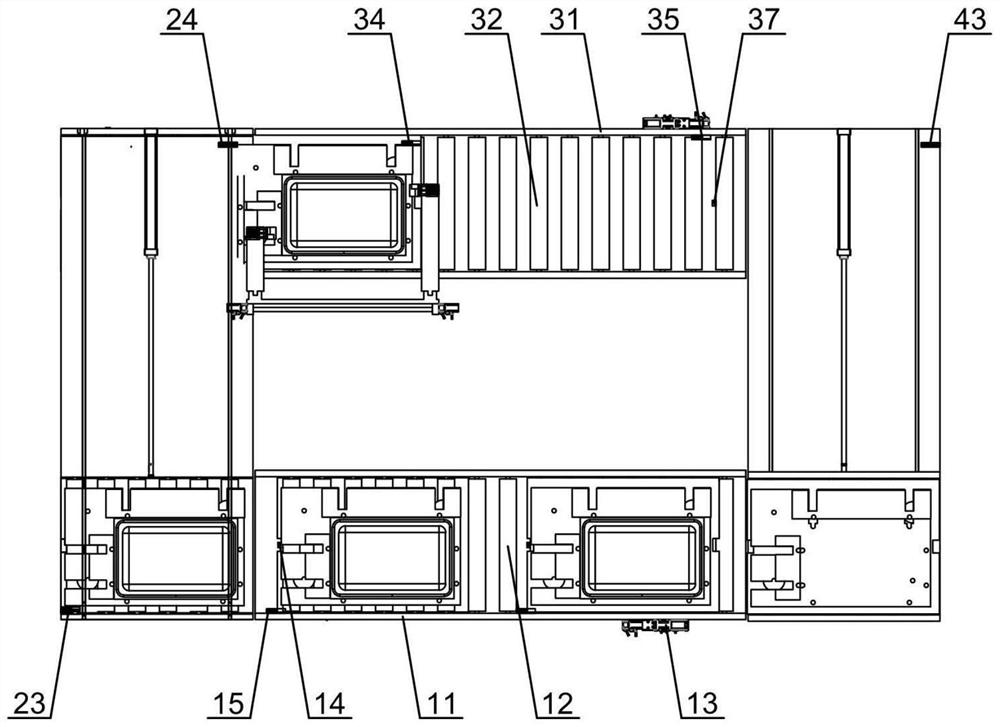

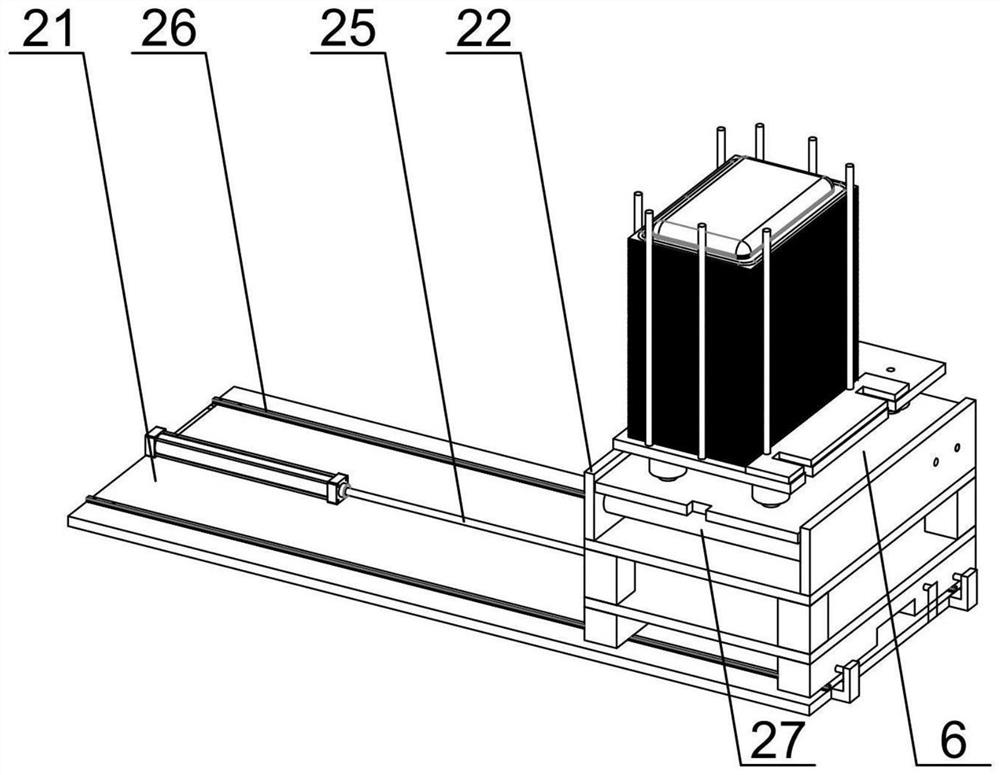

[0056] One for automatic separation of material for steam dishes, including conveying platforms, migrant workers, workpieces 6, separation and grabbing workwear 5, which includes the first conveyor platform 1. Loading includes first -loading workers 2. Second -migrant carriers 4, the first conveyor platform 1. The first transfer of the carrier 2, the second transfer platform 3. The workplace 6 is transmitted on the first conveyor platform of the first conveyor 1. The first transfer of the carrier 2, the second transfer platform 3. The transportation platform 3 is corresponding to the workplace 6 on the second conveying platform 3.

[0057] The above -mentioned control method for automatic separation of material devices for steam dishes, including the four steps of materials, transmission, materials, and recycling. The four steps of the material, transmission, division, and recycling are executed and carried out in order;

[0058] Among them, the steps are included,

[0059] A1. St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com