FPC and PCB bonding electrical performance detection method

An electrical performance detection and integration technology, applied in the field of display production and testing, can solve the problems of heavy workload, easy misjudgment, inability to accurately detect the electrical performance of FPC and PCB bonding, and achieve high accuracy and detection. Convenience and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

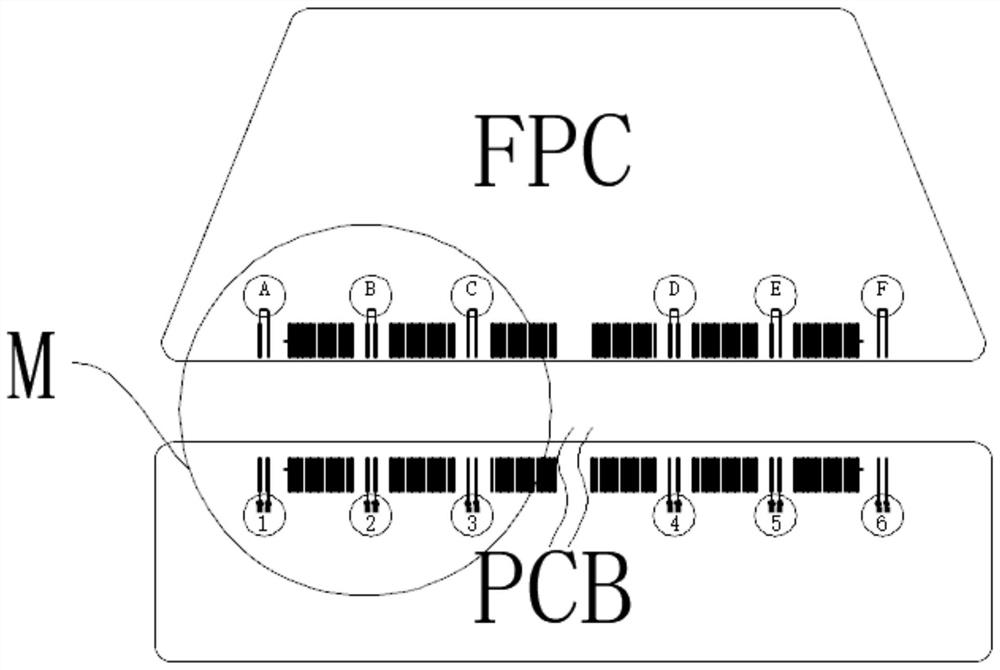

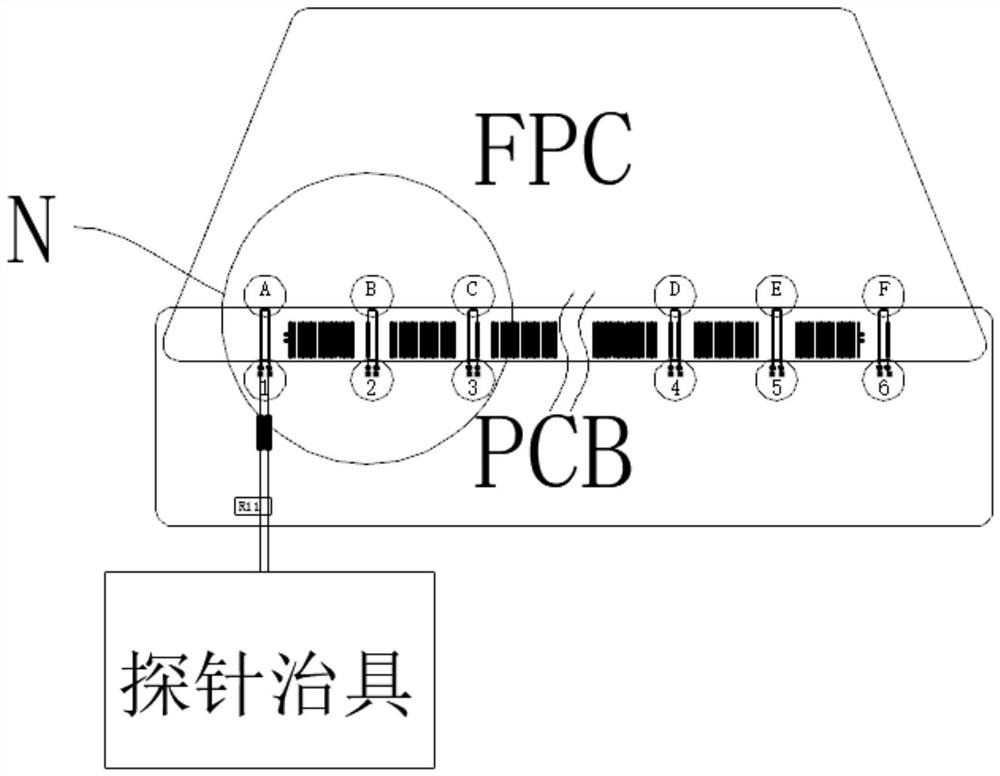

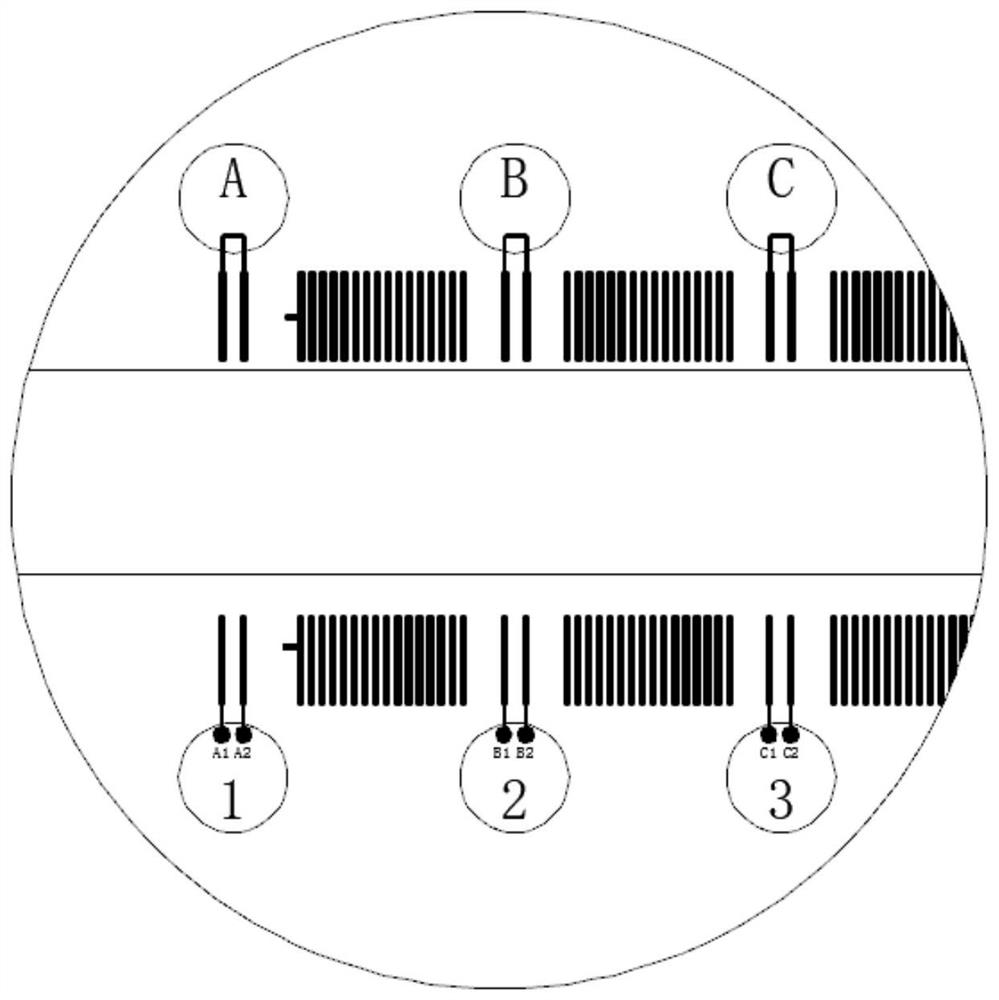

[0027] The following is attached Figure 1-5 and specific embodiments, the present invention is described in detail.

[0028] The invention provides a method for detecting the electrical performance of FPC and PCB bonding, which specifically includes the following steps:

[0029] Step 1. Establish the engineering drawing of FPC bonding PIN, and design the first golden finger corresponding to the PIN number according to the glass specification. In this embodiment, the engineering drawing is established by EDA software. Several non-display function impedance test bonding PIN loops are arranged in the first gold finger, and the PIN loops electrically connect two adjacent first gold fingers, and each of the PIN loops passes through a metal wire f Connect two adjacent first golden fingers together. The metal wire f may be copper foil, which is only used for connection and conduction between the two first gold fingers, and has a small length and negligible resistance. Such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com