Method for simulating cementation failure caused by temperature change

A technology of temperature change and cementing glue, applied in the direction of instruments, measuring devices, and mechanical devices, etc., can solve the problems of high experimental research cost, incomplete channeling range, and inability to reflect more comprehensively.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0051] Embodiment 1: Cement slurry formula 1 is under a constant confining pressure of 30MPa, the inner pressure of the casing is 25MPa, the initial temperature is 60°C, the temperature rises rapidly to 120°C within 30-40 minutes, and the temperature is kept constant for 3-4hrs, and then the cement sheath and the outer casing are inspected Whether there is a micro-annulus between the interfaces, and check the gas channeling flow rate at the same time; if micro-cracks are found, exclude formula 1, continue to test formula 2, formula 3..., find out the cement slurry formula that has not been damaged and determine it as initially suitable. Then cool down naturally or slowly (about 4 hours) to 60°C, and use the initially suitable formula to repeat steps to raise the temperature to 120°C, and the formula that can withstand the most repeated heating and cooling times when channeling occurs is the best.

Embodiment approach 2

[0052] Embodiment 2: Cement slurry formula 1 is at a constant confining pressure of 30MPa, the pressure inside the casing is 25MPa, the initial temperature is 60°C, the temperature rises rapidly to 160°C within 40-50 minutes, and the temperature is kept constant for 3-4hrs, and then the cement sheath and the outer casing are inspected Whether there is a micro-annulus between the interfaces, and check the gas channeling flow rate at the same time; if micro-cracks are found, exclude formula 1, continue to test formula 2, formula 3..., find out the cement slurry formula that has not been damaged and determine it as initially suitable. Then cool down naturally or slowly (about 4 hours) to 60°C, and use the formula that is initially considered suitable to repeat the steps to raise the temperature to 160°C, and the formula that can withstand the most repeated heating and cooling times when channeling occurs is the best.

Embodiment approach 3

[0053] Implementation Mode 3: Cement slurry formula 1 is under constant confining pressure of 35MPa, casing internal pressure of 30MPa, initial temperature of 140°C, temperature rapidly drops to 60°C within 40-50 minutes, constant temperature for 3-4hr, and then inspects cement sheath and outer casing Whether there is a micro-annulus between the interfaces, and check the gas channeling flow rate at the same time; if micro-cracks are found, exclude formula 1, continue to test formula 2, formula 3..., find out the cement slurry formula that has not been damaged and determine it as initially suitable. , use the initially suitable formula to repeat the above steps to raise the temperature to 140°C and then cool down naturally or slowly (about 4 hours) to 60°C, and the formula that can withstand the most repeated heating and cooling times when channeling occurs is the best.

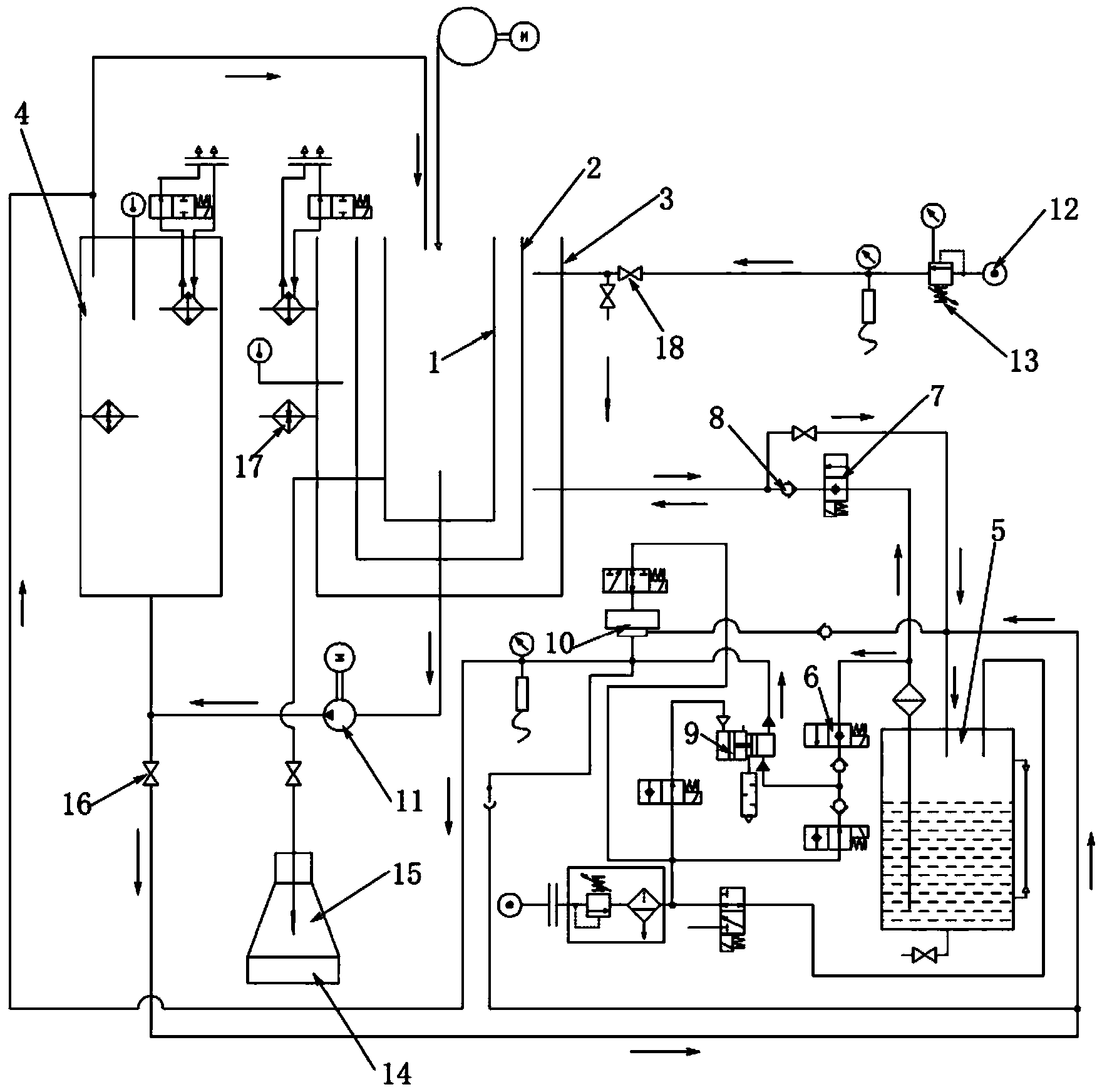

[0054] see figure 1 , the method for checking the flow of gas channeling in the above-mentioned embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com