Windshield structure

A mainboard and body technology, applied in the field of windshield structure of mainboard module, can solve the problems of weakened friction force between ribs and mainboard body, easy movement of windshield, etc., achieve good market applicability and save material cost , Easy to install and remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

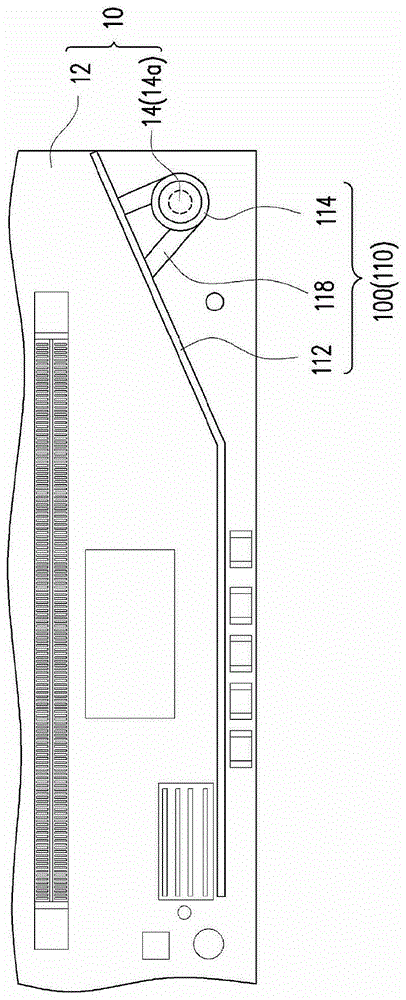

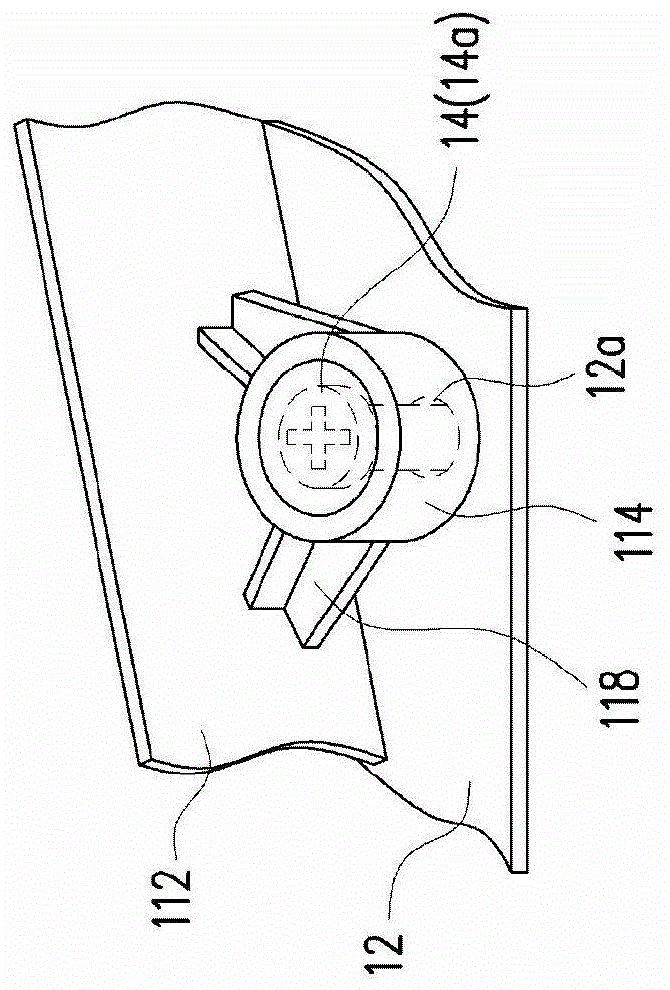

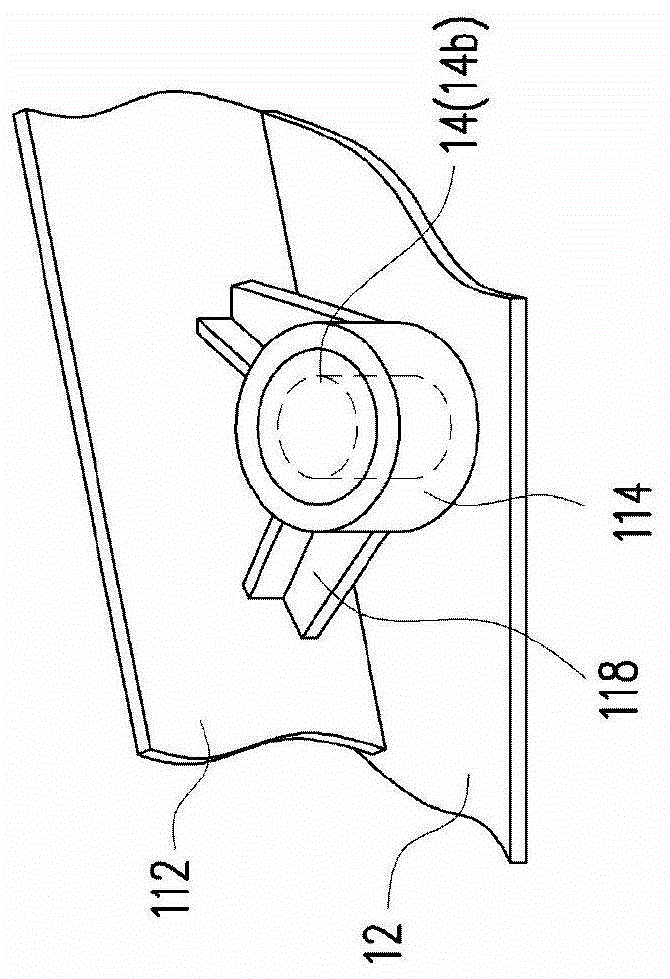

[0042] Figure 1A It is a schematic diagram of a windshield structure disposed on a motherboard module according to an embodiment of the present invention. Figure 1B yes Figure 1A The partial enlarged schematic diagram of the windshield structure provided on the motherboard module.

[0043] see Figure 1A and Figure 1B , the windshield structure 100 of this embodiment is suitable for being disposed on a motherboard module 10 . The motherboard module 10 includes a motherboard body 12 and at least one positioning portion 14 disposed on the motherboard body 12 . The positioning portion 14 protrudes from the motherboard body 12 . In this embodiment, the motherboard body 12 includes a screw hole 12a, and the positioning portion 14 includes a screw 14a. The screw 14a is disposed in the screw hole 12a and protrudes from the motherboard body 12. The screw 14a is usually used to match the motherboard body. 12 to fix the motherboard module 10 on the case (not shown). The windshiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com