The control method of the direction buffer of the oil cylinder of the integral box hopper

A control method and hopper technology, applied in the direction of fluid pressure actuators, sustainable manufacturing/processing, servo motors, etc., can solve problems such as breaking high-voltage power lines, loud working noise, and fast movement of hoppers to avoid damage , slow down the impact of stopping, and avoid the effect of displacement of the compression box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

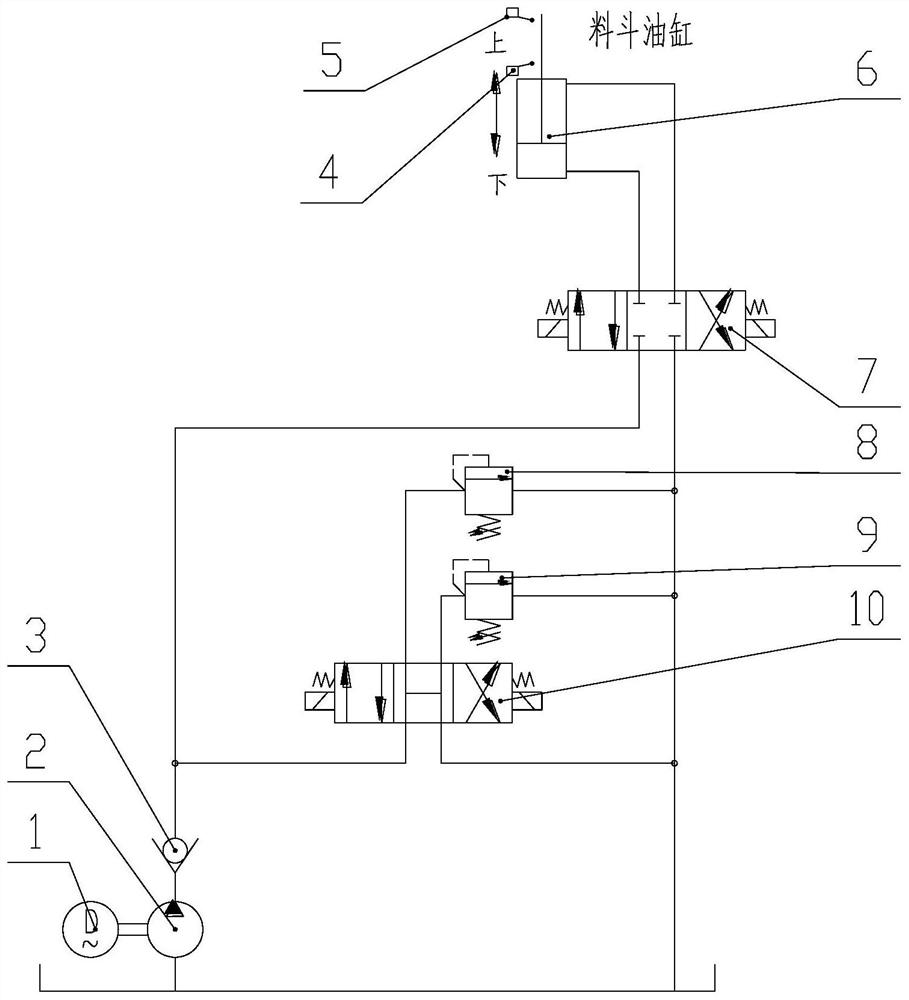

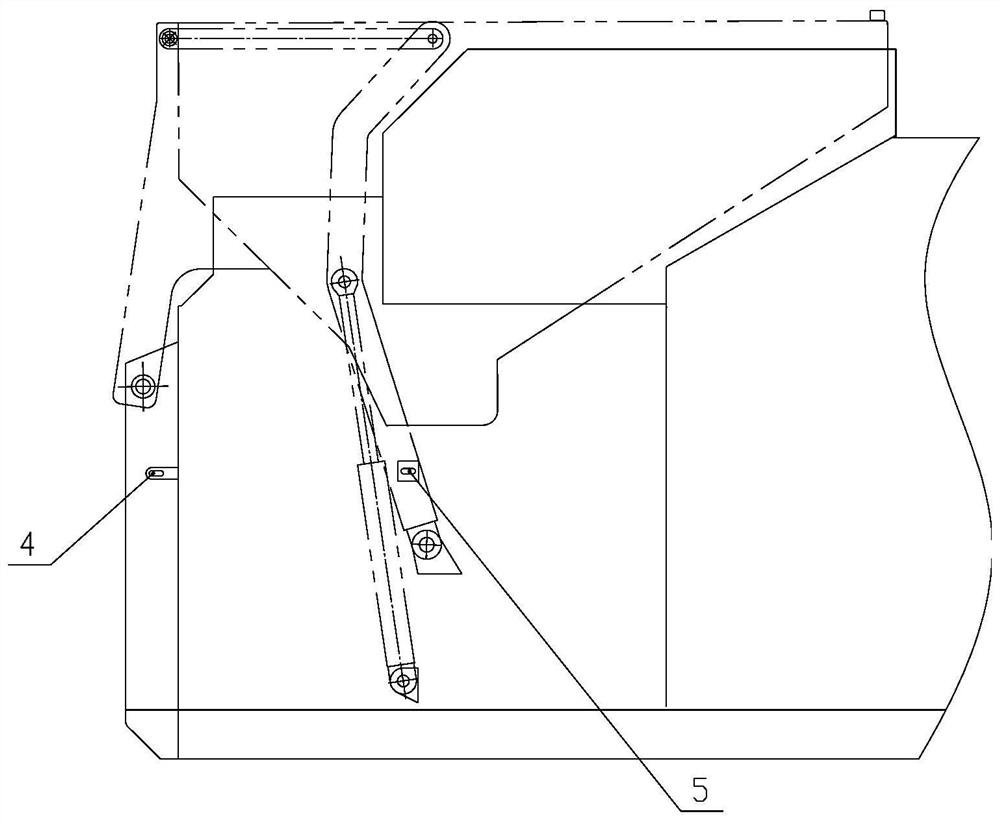

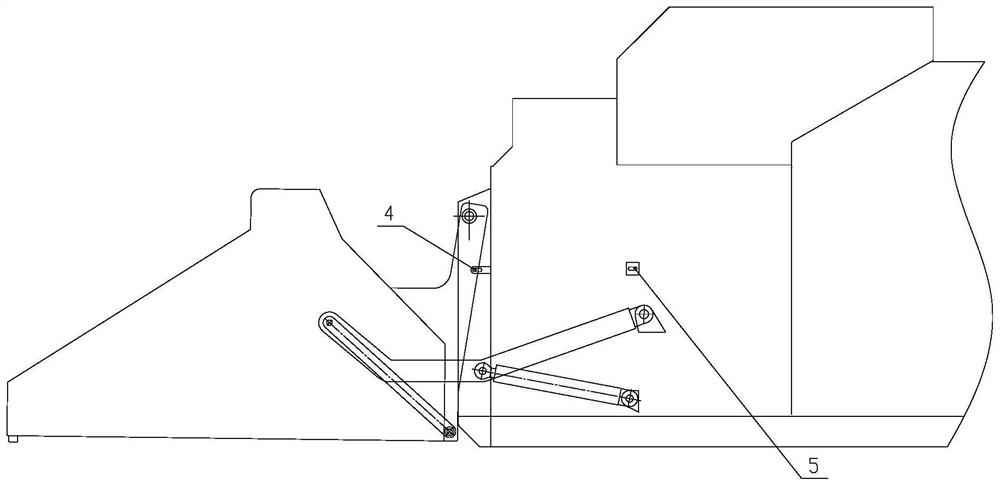

[0019] like Figure 1-3 As shown in one of the present invention, the control method for the direction buffering of the oil cylinder of the overall box hopper, the hydraulic system on which the control method is based includes a hydraulic pump 2 (the hydraulic pump 2 is driven by the motor 1), a three-position four-way electromagnetic reversing valve a7, a hopper The oil cylinder 6, the three-position four-way electromagnetic reversing valve b10, the high-pressure relief valve 8 and the low-pressure relief valve 9, the outlet of the hydraulic pump 2 is connected to the pressure oil port of the three-position four-way electromagnetic reversing valve a7, the said The two outlets of the three-position four-way electromagnetic reversing valve a7 are respectively connected to the large cavity and the small cavity of the hopper cylinder 6 through pipelines, and the oil return port of the three-position four-way electromagnetic reversing valve a7 is connected to the oil tank through p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com