DC (direct current) motor controller

A DC motor and controller technology, applied in the direction of DC motor speed/torque control, control system, electrical components, etc., can solve problems affecting work efficiency, low application efficiency, and deviation of working speed, etc., to achieve advanced control technology and save energy The effect of uniform electric energy and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

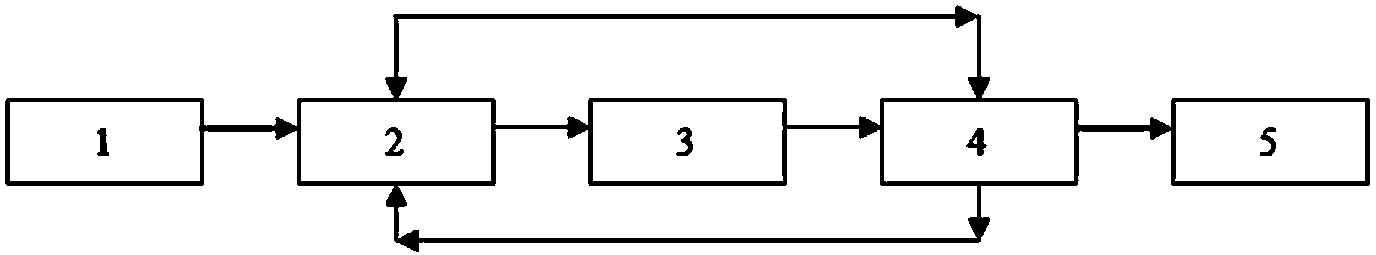

[0009] see figure 1 , the present invention includes a controller 2, an inverter 3, a DC motor 4, and an oil well pumping unit 5 connected in sequence, the controller 2 is connected with a speed sensor, and the AC 1 outputs power to the controller 2.

[0010] When the oil well pumping DC motor controller is working, the position of the carbon brush is first adjusted to the initial state. After the DC motor starts, the data of the speed sensor enters the control center through the P port 6 of the controller 2.

[0011] The controller 2, according to the data of the speed sensor, adjusts the position of the carbon brush through the P port 3 of the controller 2 in time, reverses the rotation direction of the motor, and adjusts the position of the carbon brush. Constantly adjust the position of the carbon brush according to the data of the speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com