Fastening assembly for fastening a component to a groove of a window, a door, or the like

A technology for fixing devices and components, which is applied to the suspension device of the wing leaf, leaf leaf parts, door/window accessories, etc., to achieve the effect of simple assembly and prevention of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

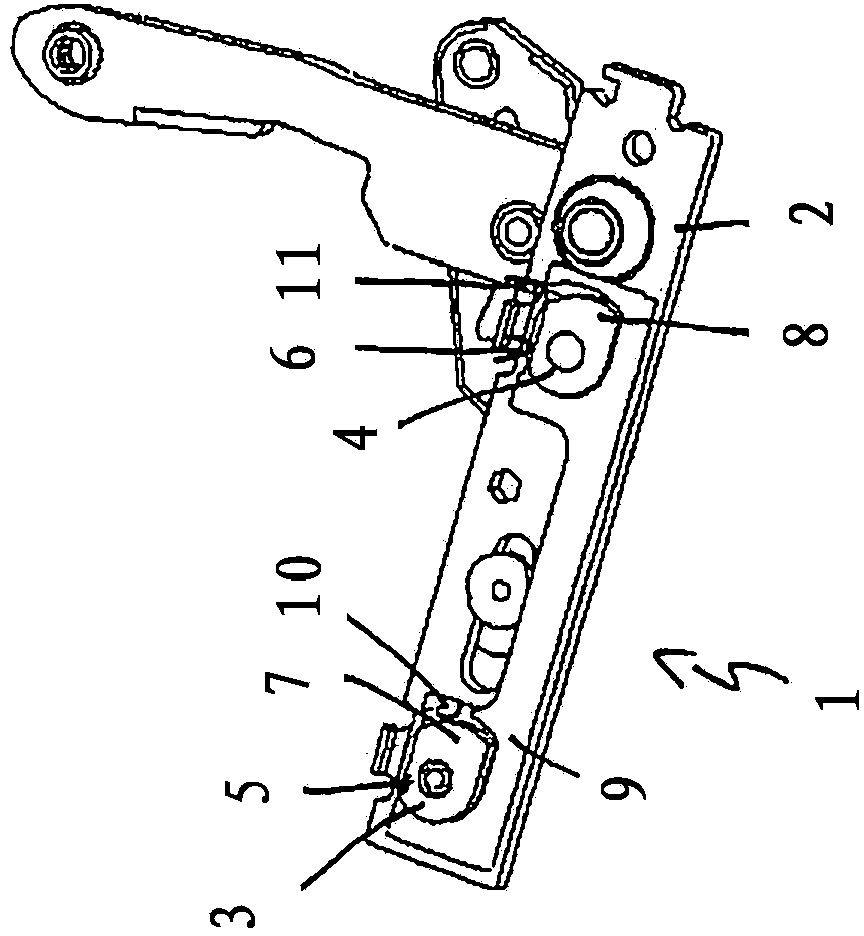

[0027] figure 1 It shows a view from below of a fastening device 1 for fastening a component 2 designed as a corner bearing to a window, door or similar structure, in particular to a fitting channel of a frame profile. The fastening device 1 has two clamping elements 3 , 4 which are held on the component 2 via screws 5 , 6 . In the assembly position shown, the screws 5 , 6 are partially screwed into the clamping elements 3 , 4 . It can be seen that the clamping elements 3 , 4 , which are rotatable about the screw axes of the screws 5 , 6 , are designed eccentrically. The clamping elements 3 , 4 each have a clamping section 7 , 8 .

[0028] The fastening device 1 also has a clamping piece 9 configured as a clamping strip. The clamping block 9 has two clamping element recesses 10 , 11 in which the clamping elements 3 , 4 are arranged.

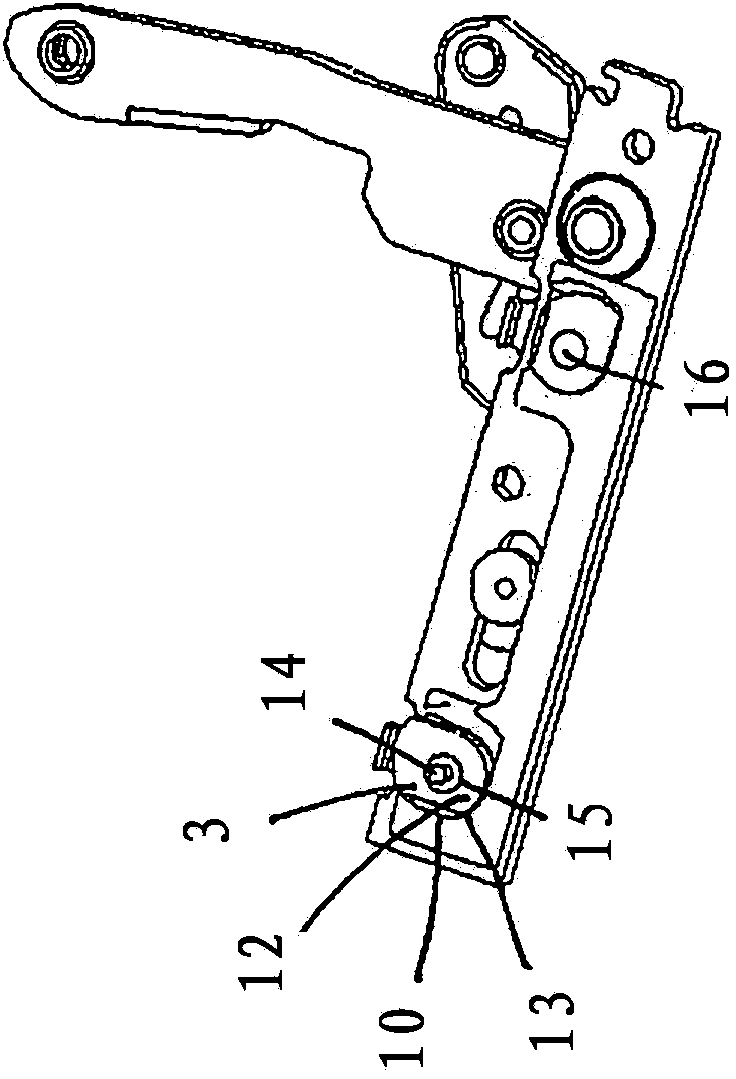

[0029] basically corresponds to figure 1 of the icon figure 2 In the illustration shown, the clamping element 3 has been rotated by 90° a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com