Ceramic powder shaping distribution method and distribution device thereof

A ceramic powder and cloth technology, applied in the manufacture of tools, supply devices, etc., can solve the problems of uneven shape, easy distortion, and stiffness of the cloth, and achieve the effect of stable shape, better effect, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] method one

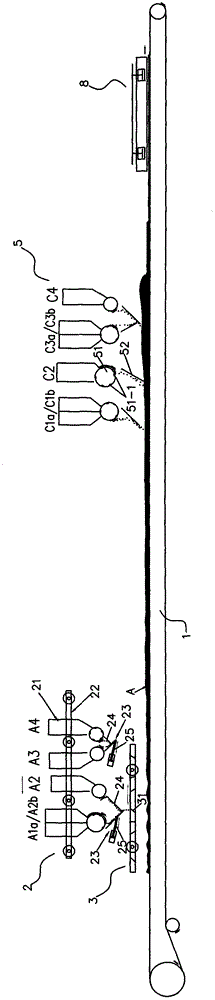

[0039] Such as figure 1 A kind of multiple pre-pressing molding ceramic cloth method shown, its steps are:

[0040] 1) Move the hopper back and forth to distribute the ceramic powder evenly on the conveying platform to form a prototype material layer;

[0041] 2) The ceramic powder of molding patterns and textures is distributed up and down on the ceramic powder of the prototype material layer;

[0042] 3) Transport the ceramic powder to the press for molding.

[0043] Method Two

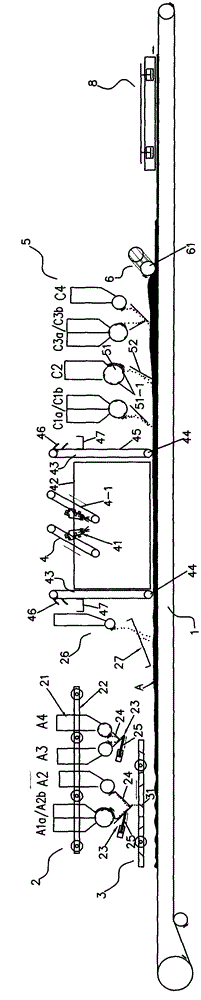

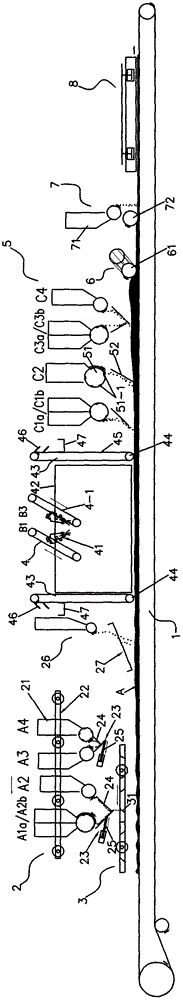

[0044] Such as figure 2 A kind of multiple pre-pressing molding ceramic cloth method shown, its steps are:

[0045] 1) Move the hopper back and forth to distribute the ceramic powder evenly on the shaper;

[0046] 2) The ceramic powder is laid on the conveying platform through the lower cloth of the shaper to form a prototype material layer;

[0047] 3) Arrange wire ceramic powder up and down the prototype material layer;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com