Manufacturing method for composite spar cap for wind power blade

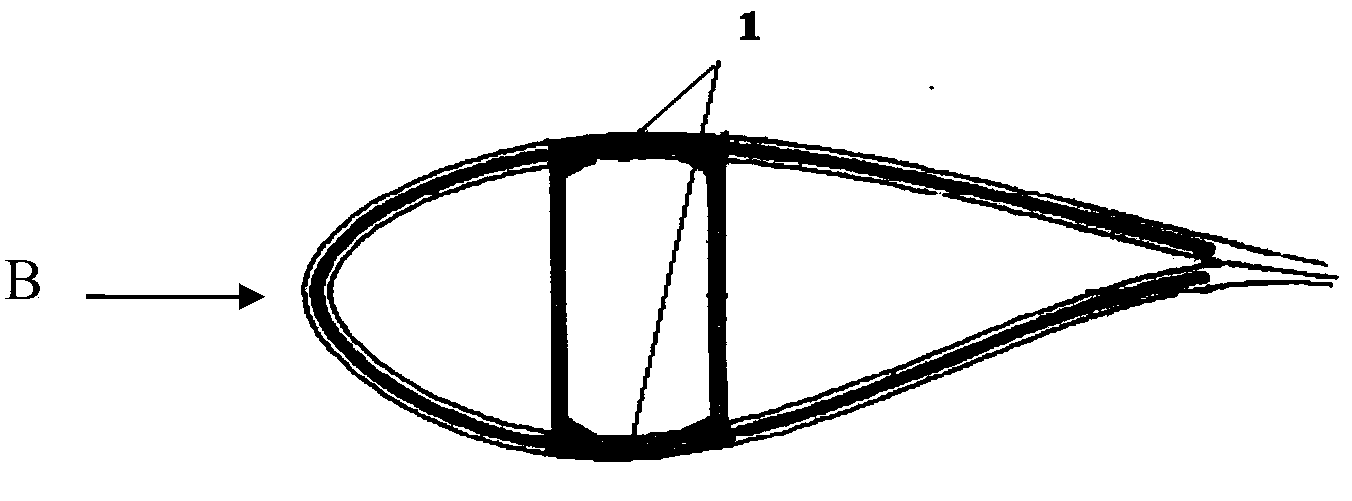

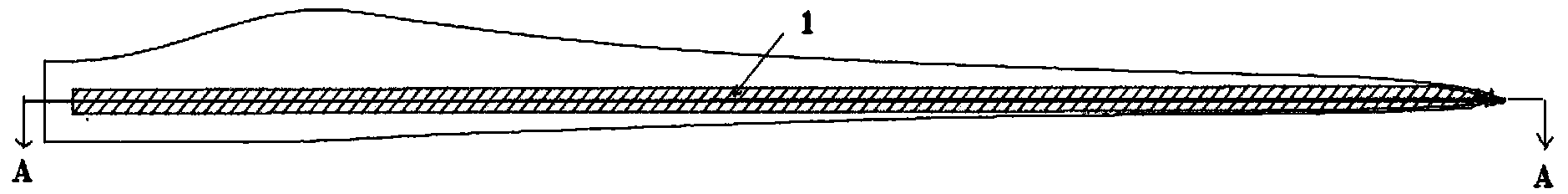

A technology of composite materials and manufacturing methods, which is applied in the production of main spar caps and the field of composite main spar caps for wind power blades, which can solve the problems of low tensile strength and elastic modulus, easy-to-touch towers with blade tips, and large Increased blade weight and other issues to achieve the effect of increasing toughness and fracture strain performance, reducing the risk of encountering lightning strikes, and improving toughness and fracture strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0061] Example 1:

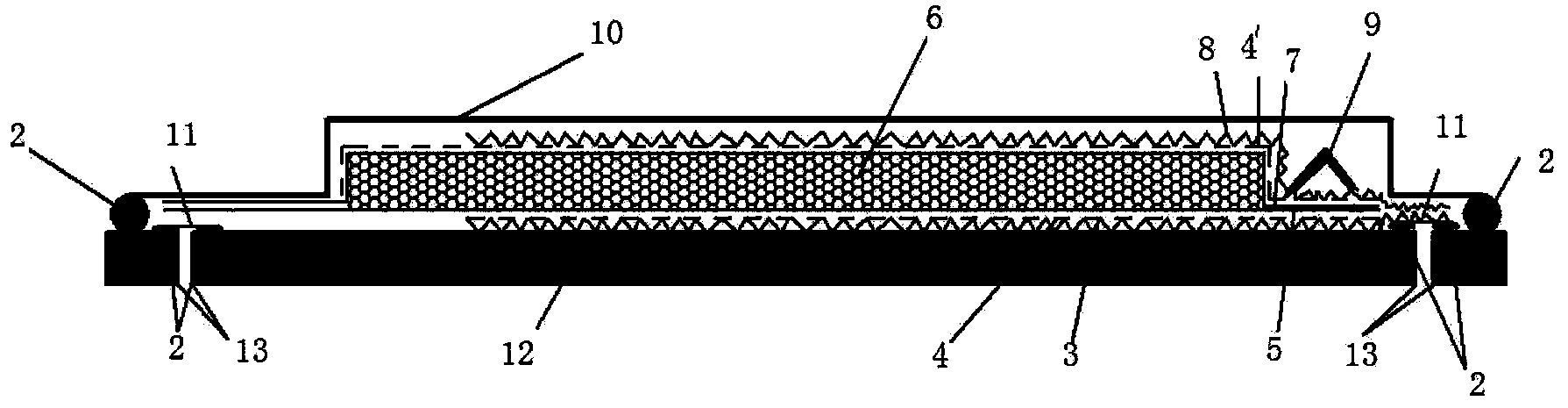

[0062] Such as image 3 , Figure 4 As shown, it is a mixed fiber preform 6 formed by layering a mixed braid 14, wherein the carbon fiber yarn tow is 12K, and the glass fiber yarn is an alkali-free glass fiber yarn.

[0063] If the volume of carbon fiber accounts for 30% of the total volume of the mixed fiber, and the volume of glass fiber accounts for 70% of the total volume of the mixed fiber, it is woven into a mixed braid 14 with an areal density of 830g / m 2 , The thickness is 0.66mm, and 60 layers are covered to form a mixed fiber preform 6 with a maximum thickness of 39.0mm.

[0064] If the volume of carbon fiber accounts for 50% of the total volume of the mixed fiber, and the volume of glass fiber accounts for 50% of the total volume of the mixed fiber, it is woven into a mixed braid 14 with an areal density of 770g / m 2 , The thickness is 0.62mm, and 53 layers are covered to form a mixed fiber preform 6 with a maximum thickness of 32.8mm.

[0065] If the volu...

Example Embodiment

[0068] Example 2:

[0069] Such as image 3 , Figure 5 As shown, it is a mixed fiber preform 6 formed by interlayer mixing of glass fiber fabric 15 and carbon fiber fabric 16. Among them, combined with the fiber length of the corresponding layer in Table 2, the volume fraction of the carbon fiber in the total volume of the mixed fiber is calculated by formula (1).

[0070] If the volume of carbon fiber accounts for 30% of the total volume of the mixed fiber, and the volume of glass fiber accounts for 70% of the total volume of the mixed fiber, the mixed fiber preform 6 with a maximum thickness of 39.0mm is formed by interlayer mixing, and the lower release cloth 5 is required. Overlay forming; the covering steps are as follows: A) First, the density of the first layer is 1200g / m 2 Glass fiber fabric with a thickness of 0.8mm; B) Pave a layer on it with a density of 380g / m 2 The thickness of the carbon fiber fabric is 0.4mm; then, after repeating step A) and step B) for 32 times, l...

Example Embodiment

[0075] Example 3:

[0076] Such as image 3 , Image 6 As shown, it is a mixed fiber preform 6 formed by a sandwich of glass fiber fabric 15 and carbon fiber fabric 16. The surface density of the carbon fiber fabric used is 600g / m 2 , The thickness is 0.55mm, the surface density of glass fiber fabric is 1200g / m 2 , The thickness is 0.8mm. Among them, combined with the fiber length of the corresponding layer in Table 2, the volume fraction of the carbon fiber in the total volume of the mixed fiber is calculated by formula (1).

[0077] If the volume of carbon fiber accounts for 30% of the total volume of the mixed fiber, and the volume of glass fiber accounts for 70% of the total volume of the mixed fiber, the mixed fiber preform 6 with a maximum thickness of 39.0mm is formed in a sandwich mode, and the lower release cloth 5 needs to be first Laying 17 layers of the glass fiber fabric 15 to form a glass fiber preform with a thickness of 13.6 mm, and then laying 22 layers of the car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com