Cascaded multi-level-based ground overvoltage phase splitting device

A cascading multi-level, over-current phase-splitting technology, which is applied to power lines, transportation and packaging, and vehicle components, can solve the problems of increasing system complexity and cost, production cut-off overvoltage, and high switch requirements, and achieves Feed-through power supply, reducing requirements, avoiding cut-off overvoltage and closing surge overcurrent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

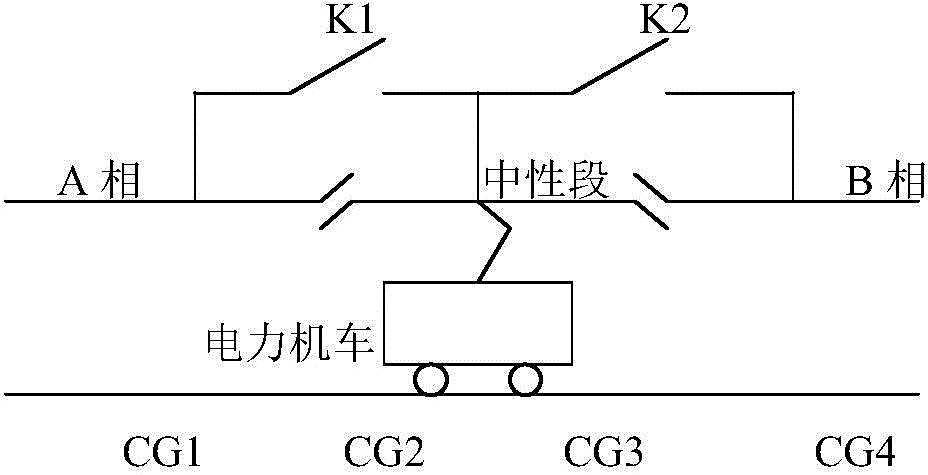

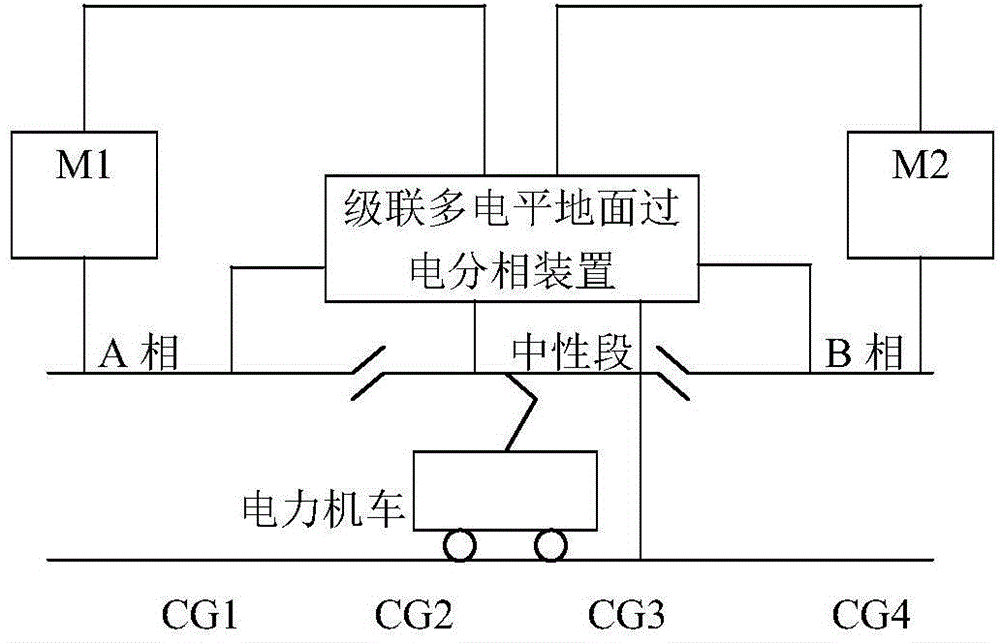

[0019] According to the determination of locomotive position by locomotive position sensors CG1, CG2, CG3 and CG4 on the track and the determination of catenary A and B phase voltage phases by catenary voltage phase detection modules M1 and M2 for measuring the catenary voltage phase , the output voltage is controlled by the controller of the cascaded multi-level ground over-current phase-splitting device, so that the electric locomotive can pass through the phase-separation flexibly. image 3 It is a system structure diagram of the cascaded multi-level ground overcurrent phase-splitting device designed by the present invention.

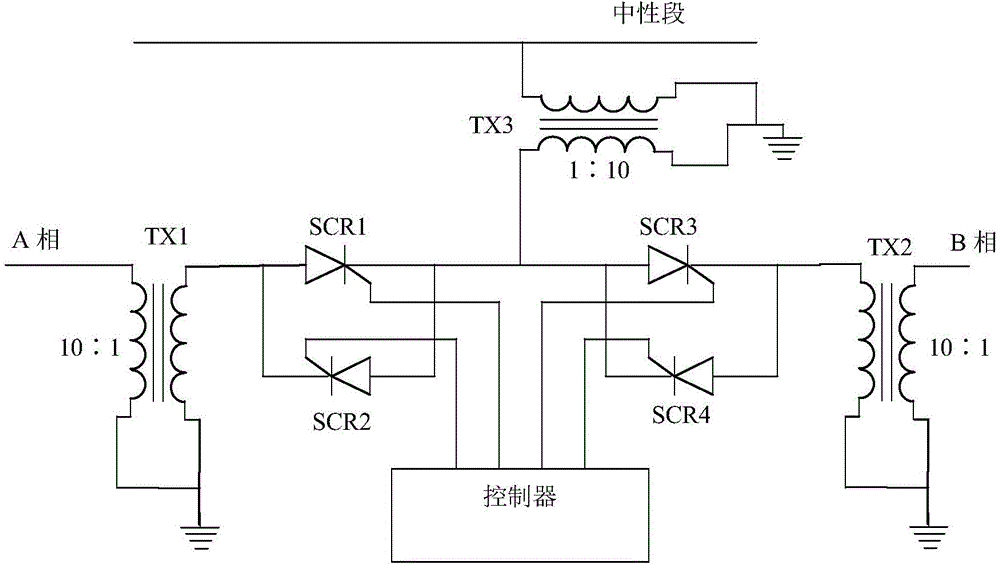

[0020] According to the existing technology, the cascaded multi-level ground overvoltage phase-splitting device can adopt the following structure: 1) cascaded H-bridge rectifier + cascaded H-bridge inverter; 2) cascaded H-bridge rectifier + ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com