Automatic film sealing device and packaging device for section bars

A technology for sealing films and profiles, applied in the field of automatic profile sealing devices and packaging devices, can solve the problems of high labor intensity, insufficient aesthetics, low labor efficiency, etc., and achieve the effects of reduced labor intensity, high firmness, and reasonable structure.

Active Publication Date: 2014-05-28

新疆蓝山屯河型材有限公司

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The present invention provides an automatic profile sealing device and packaging device, which overcomes the above-mentioned deficiencies in the prior art, and can effectively solve the problem of manual packing of profiles time-consuming, labor-intensive, time-consuming, and low-efficiency; and manual packaging also has the problems of poor firmness, easy damage, and insufficient aesthetics.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

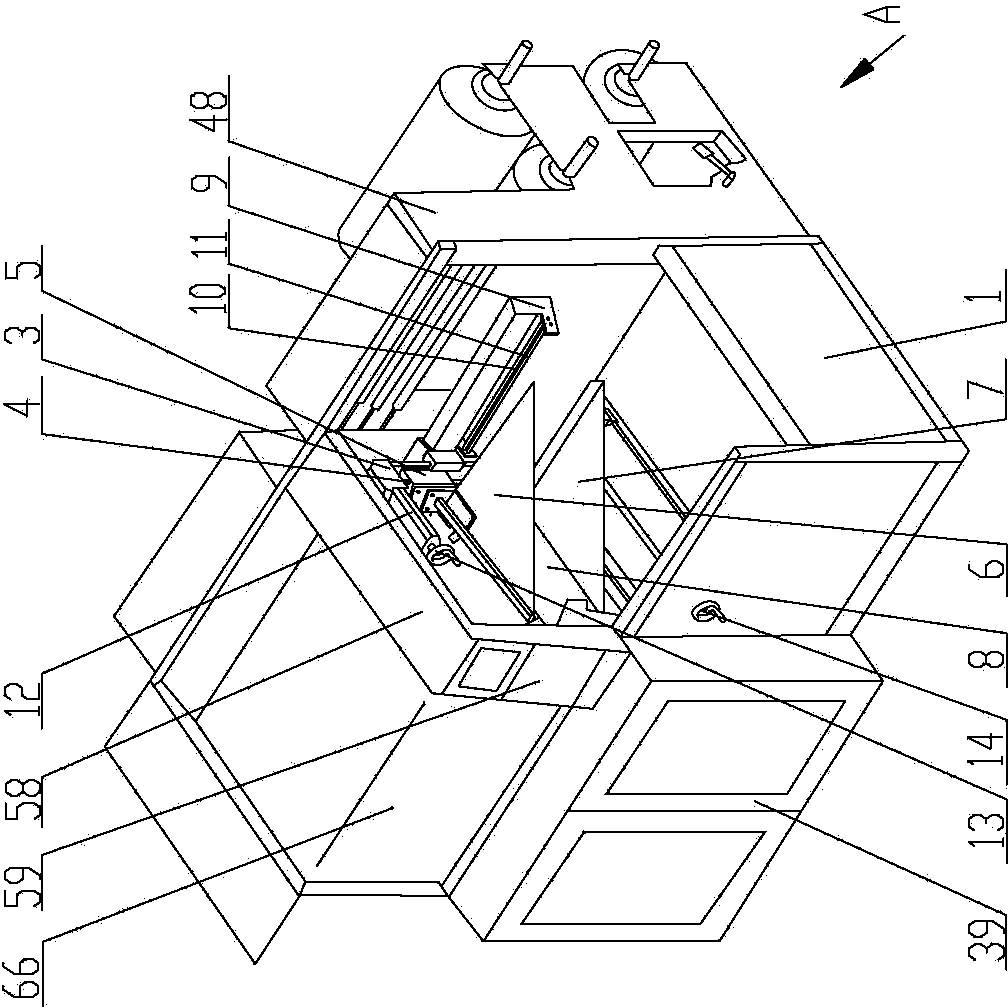

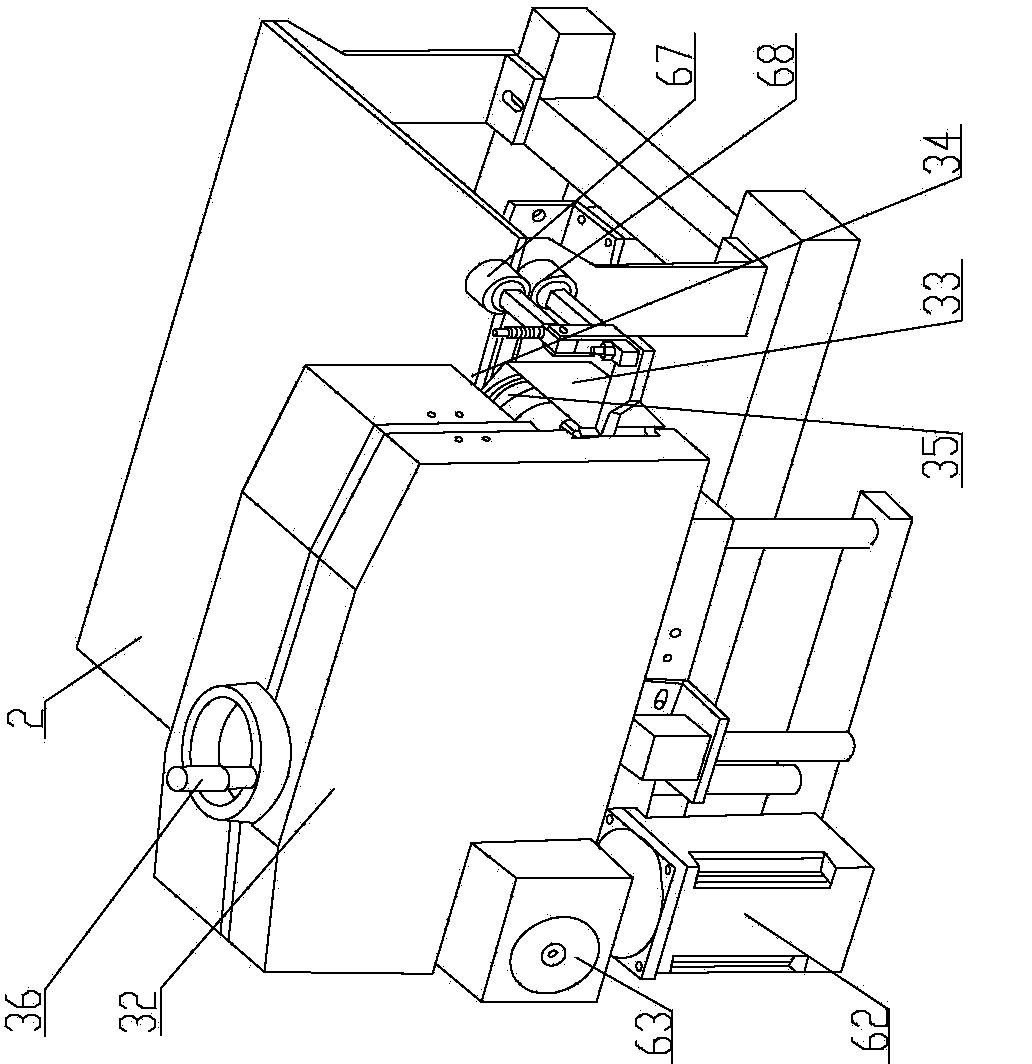

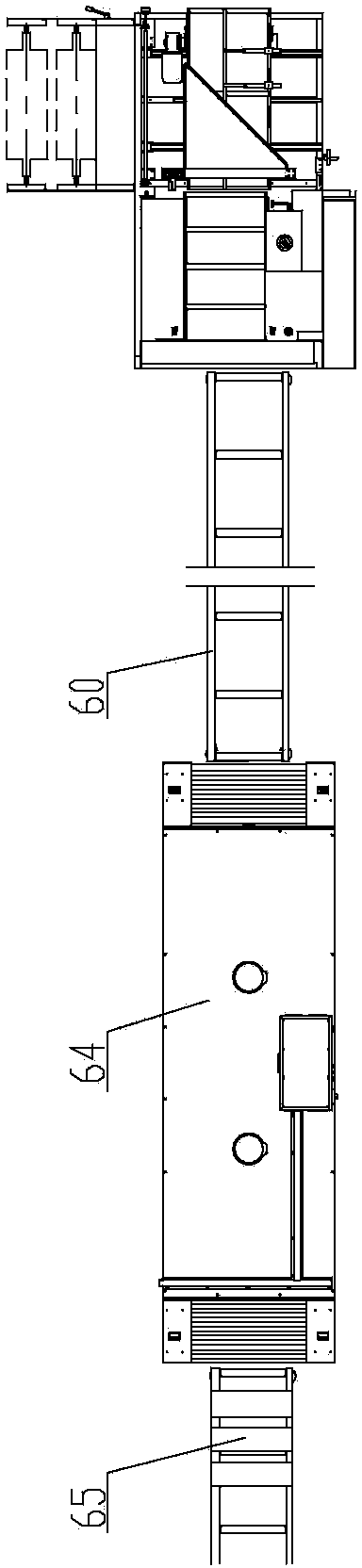

The invention relates to the technical field of packaging devices for section bars, and discloses an automatic film sealing device and a packaging device for section bars. The automatic film sealing device comprises a case, a film sleeving device, a film sealing platform, a longitudinal edge heat-sealing, film guiding and cutting device and a transverse opening heat-sealing and cutting device. The film sleeving device which can package a U-shaped packaging film on the outside of a section bar is mounted in the front of the case and comprises an upper film sealing suspension plate and a lower film sealing suspension plate; the upper film sealing suspension plate and the lower film sealing suspension plate are vertically mounted on the case at intervals and form a film sealing feeding channel; both the edge of the front end of the upper film sealing suspension plate and the edge of the front end of the lower film sealing suspension plate are wedge-shaped edges which are leftwards oblique towards the rear sides; the film sealing platform is mounted on the case and is positioned on the rear side of the lower film sealing suspension plate. The automatic film sealing device and the packaging device have the advantages that the automatic film sealing device and the packaging device are reasonable and compact in structure and convenient to use; a series film sealing, heat-sealing and film wrapping actions are carried out on the section bar, so that mechanical film sealing and packaging can be implemented on the section bar, the labor intensity can be reduced, and the packaging efficiency can be improved; the packaged section bar is high in firmness and neat and attractive in appearance, and is damp-proof, breakage-proof.

Description

technical field [0001] The invention relates to the technical field of profile packaging devices, and relates to a profile automatic film sealing device and a packaging device. Background technique [0002] In the processing and production process of profiles, in order to facilitate the storage and transportation of profiles, it is necessary to pack and seal the produced profiles; usually manual packing is used, that is, the packing staff in the workshop manually bundle the profiles, and then pack them In the packaging film, the two ports of the packaging film are sealed with adhesive tape; while the binding and packaging process requires the cooperation of two or more operators, which is labor-intensive, time-consuming, and low in packaging efficiency; at the same time, manual packaging is required. There are also problems such as poor firmness, easy damage, and insufficient aesthetics. Contents of the invention [0003] The invention provides an automatic profile sealin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B65B11/02B65B51/10

Inventor 陈建文翟玲李强王廷举李发明李自银

Owner 新疆蓝山屯河型材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com