Step-by-step separation system and method for extracting salts from coking HPF desulfurizing solution by aqueous phase method

A desulfurization liquid and water phase technology, applied in the direction of thiosulfate/dithionite/polythionate, thiocyanate, etc., can solve the problems of reduced desulfurization effect, inability to biochemical treatment, production system corrosion, etc. Achieve the effect of realizing zero discharge of pollution control, realizing comprehensive recycling of resources, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

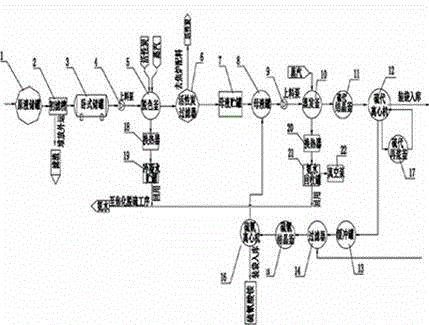

[0030] A coking HPF desulfurization liquid aqueous phase method step-by-step separation salt extraction system such as figure 1 As shown, the process flow of the present invention is: decolorization - filtration - concentration - filtration - crystallization - filtration - crystallization - finished product. Specifically: the desulfurization liquid in the coking plant is input into the raw liquid storage tank 1 through the pipeline, and flows into the primary filter tank 2 through the pipeline. The primary filter tank 2 is an open structure, and a filter cloth is laid inside. The bottom enters the horizontal storage tank 3; the desulfurization liquid in the horizontal storage tank 3 enters the decolorization kettle 5 through the feeding pump 4. 98 o Above C, an electric stirrer is installed in the kettle, and activated carbon is added into the kettle. After the desulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com