Tamping equipment for experimental coke oven samples

An experimental coke oven and equipment technology, applied in coke ovens, mechanical treatment of coal loaded into the oven, and petroleum industry, etc., can solve problems such as unsuitable gas compression, coal splashing, and coking quality differences, so as to avoid metal fatigue, Avoid the effect of coal splashing with air and the effect that air cannot be discharged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below, and it should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

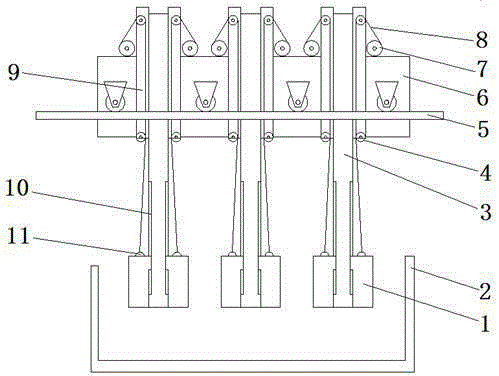

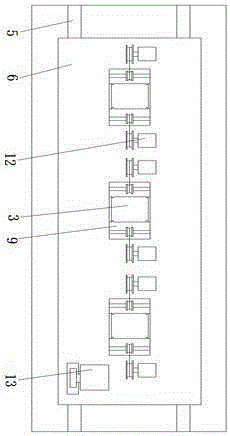

[0015] The tamping equipment used for the experimental coke oven material sample includes a car body 6, and the wheels of the car body 6 are arranged on the track 5 on the top of the coal box 2, so that the car body 6 can move freely on the top of the coal box 2. The vehicle body 6 is evenly provided with three sets of first slide rails 9, and a tamping hammer 3 is slidably arranged in the first slide rail 9. The bottom sides of the tamping hammer 3 are provided with second slide rails 10. The sliding rail 10 is slidably connected to the sliding hammer 1, and the sliding hammer 1 is provided with a lifting ring 11, the lifting ring 11 is connected to one end of the wire 8, and the other end of the wire 8 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com