A multi-component compound refinement modification treatment method for Fe phase in high Fe Al-Si alloy

An aluminum-silicon alloy and multi-component composite technology is applied in the field of multi-component composite refinement and metamorphism treatment of Fe phase in high Fe aluminum-silicon alloy, which can solve the problems of high cost and pollution of primary aluminum, and achieves easy composition, improved performance and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 Al-11Si-2Cu-1Fe Alloy Composite Refining and Modification Treatment

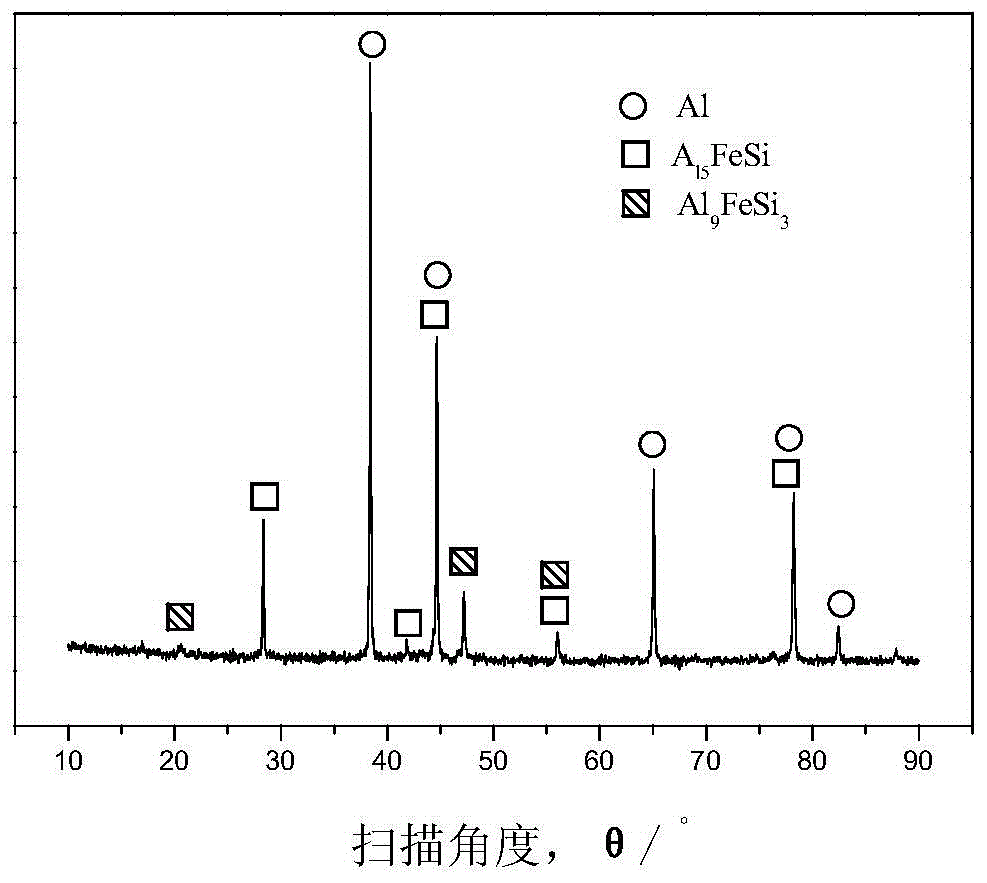

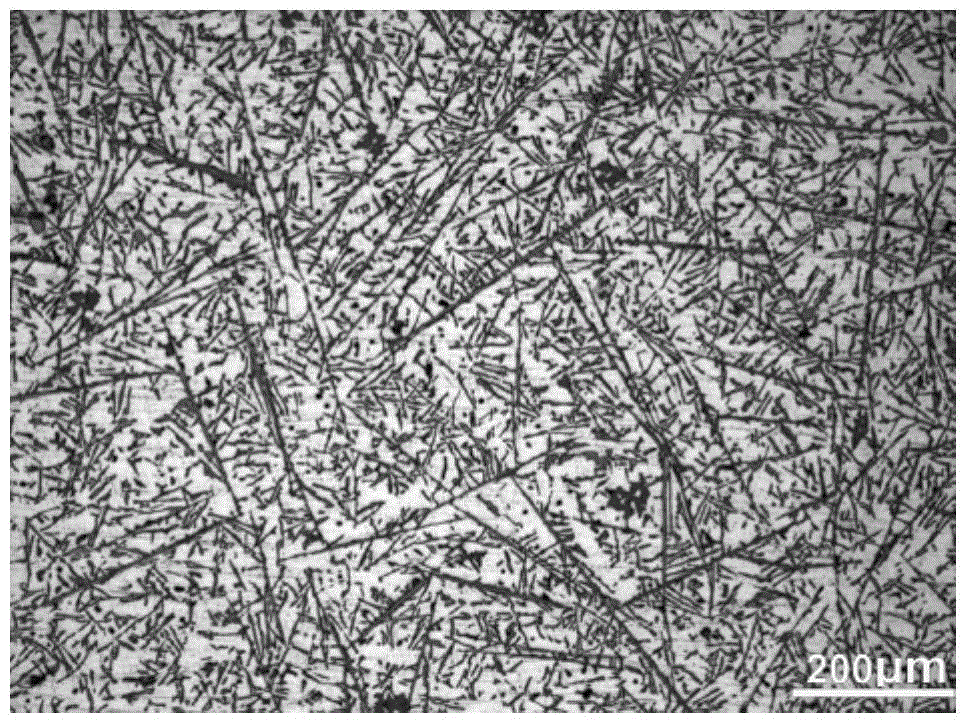

[0051] First, determine the alloy composition of the high-Fe Al-Si alloy of this embodiment by ICP spectral analysis. The specific composition is shown in 1# in Table 1. The mass percentage of Fe in this alloy is 1.05%, which belongs to the high-iron ADC12 cast Al-Si alloy. Take the original sample, XRD data such as figure 1 Shown; metallographic structure as image 3 shown. In this embodiment, Al—Ti—C, 1.0 times Mn, and 0.08 times RE are added to the mass percent of Fe.

[0052] In the high-Fe aluminum-silicon alloy of the present embodiment, the multi-element composite refinement modification treatment method of Fe phase is specifically as follows:

[0053] (1) Weigh the mass of 1# alloy as A (g). The alloy is smelted in a well-type resistance furnace and a corundum crucible. Put the alloy into a corundum crucible, sprinkle the covering agent when it is preheated to 400°C, and wait fo...

Embodiment 2

[0057] Example 2 Al-11Si-2Cu-1Fe Alloy Composite Refining and Modification Treatment

[0058] First, the alloy composition of the high-iron aluminum-silicon alloy is determined by ICP spectral analysis. The specific composition is shown in Table 1, 1#. The mass percentage of Fe in this alloy is 1.05%, which belongs to the high-iron ADC12 cast aluminum-silicon alloy. original sample gold image 3 As shown, in this embodiment, Al—Ti—C, 0.2 times of Mn, and 0.01 times of RE are added in mass percentages of Fe.

[0059] In the high-Fe aluminum-silicon alloy of the present embodiment, the multi-element composite refinement modification treatment method of Fe phase is specifically as follows:

[0060] (1) Weigh the mass of 1# alloy as A (g). The alloy is smelted in a well-type resistance furnace and a corundum crucible. Put the alloy into a corundum crucible, sprinkle the covering agent when it is preheated to 400°C, and wait for the alloy to melt when the temperature rises to 70...

Embodiment 3

[0063] Example 3 Al-12Si-0.5Cu-1Fe Alloy Composite Refining and Modification Treatment

[0064] Firstly, the alloy composition of the high-iron aluminum-silicon alloy is determined by ICP spectral analysis. The specific composition is shown in Table 1, 2#. The mass percentage of Fe in this alloy is 0.95%, which belongs to the high-iron ADC12 cast aluminum-silicon alloy. Metallographic structure such as Figure 6 shown, with figure 1 In comparison, as the silicon content increases, the copper content decreases, and the long acicular iron phase changes less. In this embodiment, Al—Ti—C, 2.0 times of Mn, and 0.1 times of RE are added with a mass percentage of 1.0 times that of Fe.

[0065] In the high-Fe aluminum-silicon alloy of the present embodiment, the multi-element composite refinement modification treatment method of Fe phase is specifically as follows:

[0066] (1) Weigh the mass of 1# alloy as A (g). The alloy is smelted in a well-type resistance furnace and a corund...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com