Concrete pump truck safety working warning system

A technology for concrete pump trucks and safe work, which is applied in the fields of construction, building structure, and building materials processing. It can solve the problems of no early warning system, delay in equipment maintenance time, and lack of safety awareness, so as to reduce personal safety threats and quickly Troubleshooting, Reduced Staffing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings.

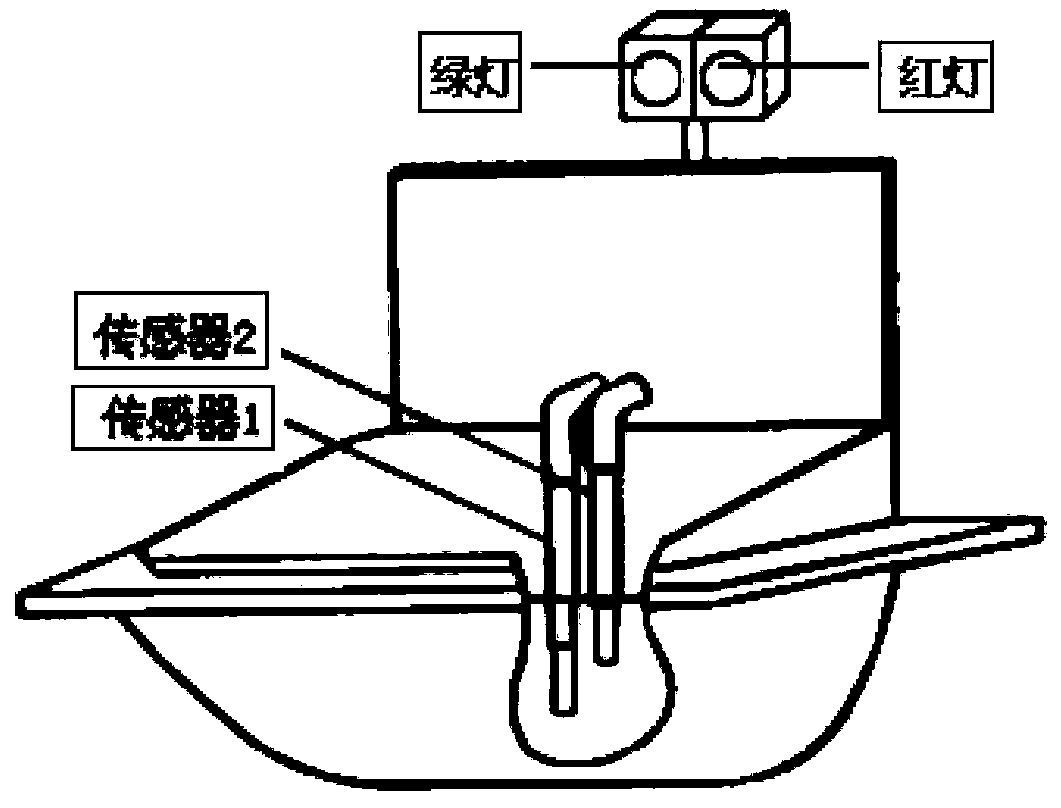

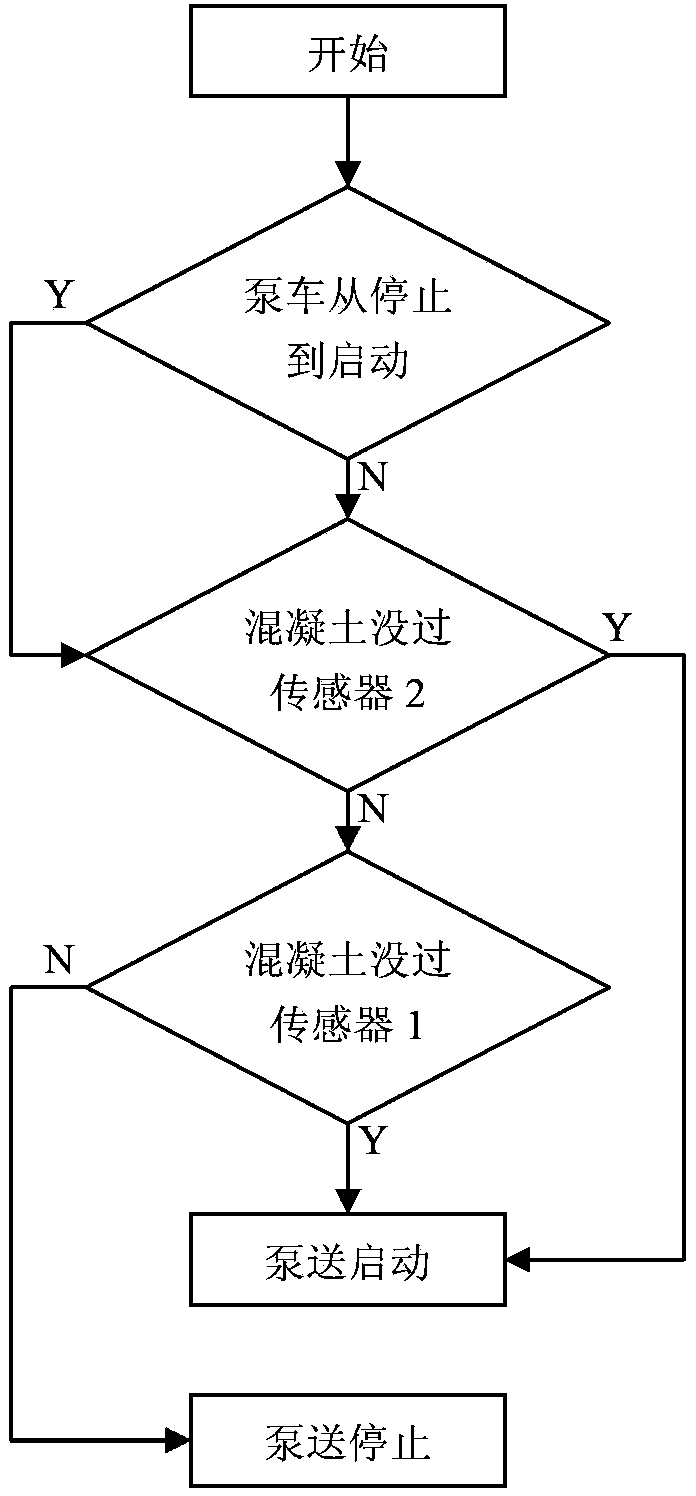

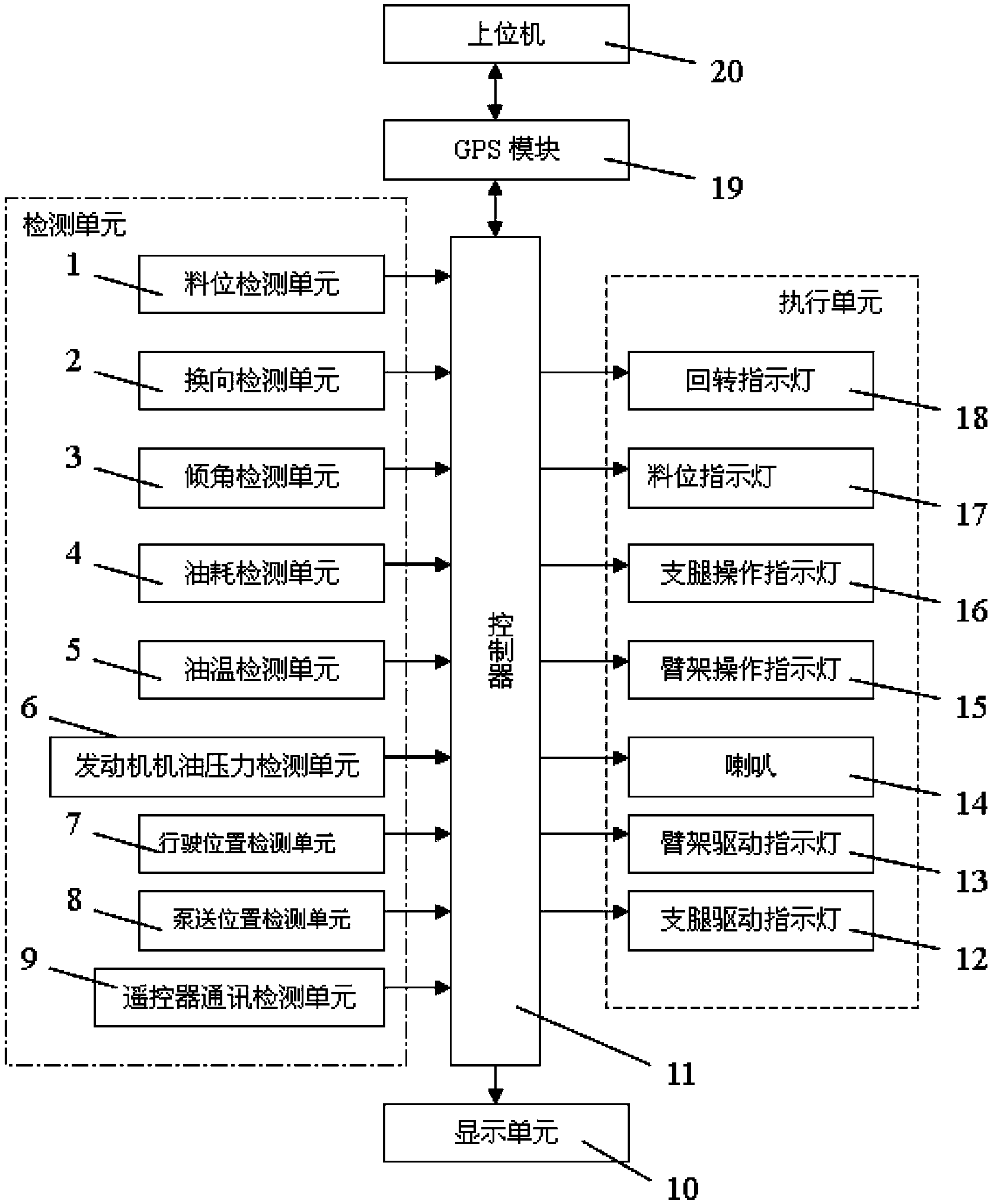

[0021] Such as image 3 As shown, the concrete pump truck safety work early warning system includes a detection unit, an execution unit, a controller 11, a display unit 10, a host computer 20, a GPS module 19, a remote controller, and the detection unit, the execution unit, and the display unit 10 are connected to the controller respectively. 11, the controller 11 communicates data with the host computer 20 through the GPS module 19, and the remote controller performs remote control on the concrete pump truck. The host computer 20, GPS module 19 and remote controller are installed in the remote monitoring room. The controller 11 and the display unit 10 are installed on the concrete pump truck. The detection unit includes a material level detection unit 1, a reversing detection unit 2, an inclination detection unit 3, a fuel consumption detection unit 4, an oil temperature d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com