Full-closed multi-speed buffering driven hydraulic cylinder

A fully enclosed, hydraulic cylinder technology, applied in the field of hydraulic cylinders, can solve the problems of large impact force, single buffer speed, and non-adjustable buffer speed of hydraulic cylinders, and achieve the effects of preventing impact or cylinder explosion, prolonging practical life, and avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

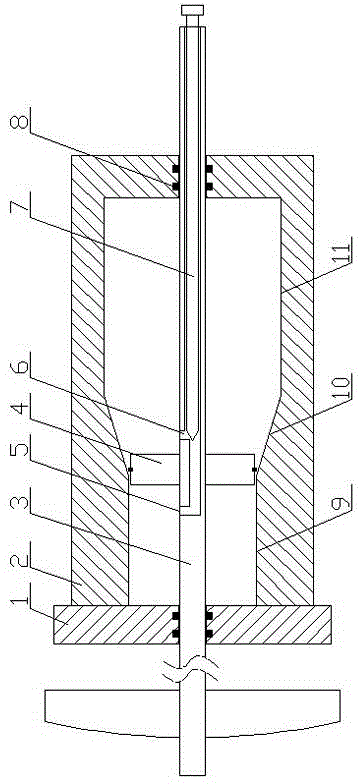

[0018] As shown in the figure, a fully enclosed multi-speed buffer passive hydraulic cylinder includes an end cover 1, a cylinder body 2, a piston shaft 3, a piston 4, a left through hole 5, a right through hole 6, an adjusting screw 7, a sealing ring 8, and a low-speed section 9, transition section 10, fast section 11. The end cover 1 is airtightly connected to the left end surface of the cylinder body 2, the cylinder body 2 is filled with hydraulic oil, the piston shaft 3 is coaxially connected to the cylinder body 2 and the end cover 1, and the piston shaft 3 is connected to the cylinder body 2 and the end cover A sealing ring 8 is provided in the first room, the piston 4 is fixed on the piston shaft 3, the piston 4 is connected to the inner wall of the cylinder through the sealing ring, and the inner chamber of the cylinder is divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com