Anti-theft and anti-disassembly nut shield

A technology for shields and nuts, which is applied to nuts, bolts, threaded fasteners, etc., can solve the problems of failure to achieve popularization and application, and high manufacturing costs, and achieve the effects of simple structure, reduced production costs, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

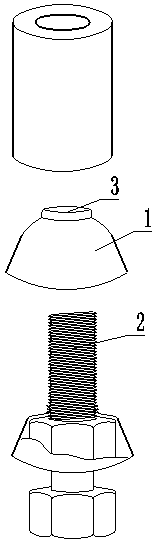

[0013] A nut anti-theft and unloading protective cover. The nut anti-theft and unloading protective cover is a hollow cone structure. The upper part of the cone 1 is provided with a circular hole matching the bolt 2 and the upper part of the circular hole is provided with a boss 3 along the circumferential direction , The middle of the boss 3 is provided with a central hole matching the bolt 2. In the tightening process, a round tube is used to punch or press the anti-theft shield with ordinary nuts to make the boss of the anti-theft shield into a flat surface, and then hold the bolts to achieve the anti-theft function.

Embodiment 2

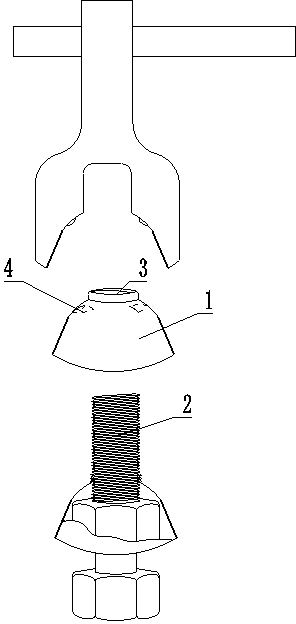

[0015] A nut anti-theft and unloading protective cover. The nut anti-theft and unloading protective cover is a hollow cone structure. The upper part of the cone 1 is provided with a threaded hole matching the bolt 2 and the upper part of the threaded hole is provided with a boss 3 in the circumferential direction , The middle of the boss 3 is provided with a threaded hole that matches the bolt 2, and the outer wall of the nut anti-theft shield is provided with a slot 4, and the left side of the slot 4 is perpendicular to the nut anti-theft shield On the outer wall of the cover, the recess on the right side of the slot 4 is arc-shaped to transition to the outer wall of the nut anti-theft protection cover. During the tightening process, a special clamp is used to rotate clockwise to tighten the cone, and when the clamp is rotated counterclockwise, the cone cannot be disassembled due to the slippage of the clamp, thus realizing the anti-theft and unloading effect of the nut.

Embodiment 3

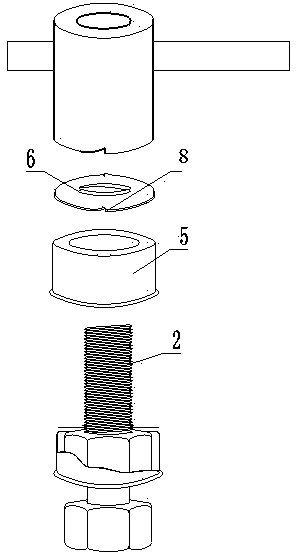

[0017] A nut anti-theft and unloading protective cover. The nut anti-theft and unloading protective cover is mainly composed of a cylindrical cover body 5 and an anti-theft protective pad 6. The cylindrical cover body 5 is a hollow cylinder structure, and the upper part of the cylinder body is provided with a bolt 2 The outer diameter of the anti-theft pad 6 is smaller than the outer diameter of the cylindrical cover 5, and a threaded hole matching the bolt 2 is provided in the middle of the anti-theft pad 6, and the outer circumference of the anti-theft pad 6 is provided There is a card table 8, the right side of the card table 8 maintains the circular plane structure of the anti-theft pad 6, and the left side of the card table 8 transitions to the circular plane of the anti-theft pad 6 in an arc surface. During the tightening process, a special clamp is used to rotate clockwise to tighten the anti-theft pad. When the anti-theft pad is rotated counterclockwise, the anti-theft p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com