Waste heat collection device for furfural production

A collection device and furfural technology, which is applied in the field of furfural production and combined heating and cooling systems, can solve the problems of reducing energy consumption, waste of resources, and reducing costs for unfavorable enterprises, and achieve the goals of reducing energy consumption, improving production efficiency, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

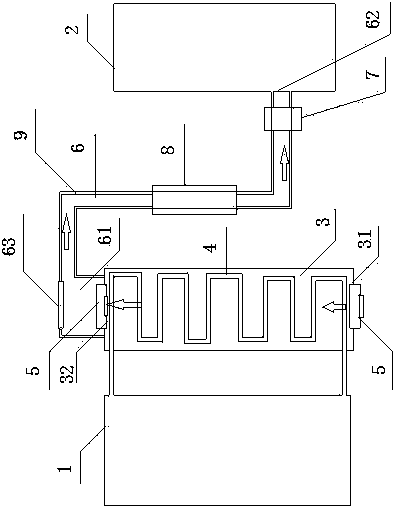

[0014] figure 1 As shown, the waste heat collection device for furfural production includes a heat dissipation air duct 3, a furfural gas heat sink 4 installed in the heat dissipation air duct 3, and the air inlet 31 and the air outlet 32 of the heat dissipation air duct 3 are equipped with first The exhaust fan 5 ; the air outlet 32 of the cooling air channel 3 communicates with the air inlet end 61 of the hot air pipe 6 ; the exhaust end 62 of the hot air pipe 6 communicates with the drying workshop 2 .

[0015] Different from the traditional open heat dissipation method for condensed water, the present invention adopts a heat dissipation air duct 3 with a closed structure to collect the heat dissipated by the furfural gas heat sink 4, and the first exhaust fans at the inlet and outlet of the heat dissipation air duct 3 pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com