Auxiliary heating device and control method for 3D printer

A 3D printer and auxiliary heating technology, which is used in the direction of manufacturing auxiliary devices, processing heating elements, additive processing, etc., which can solve problems such as slow heating speed, low temperature control and position control accuracy, and difficult to effectively reduce impact. The effect of achieving precise control of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

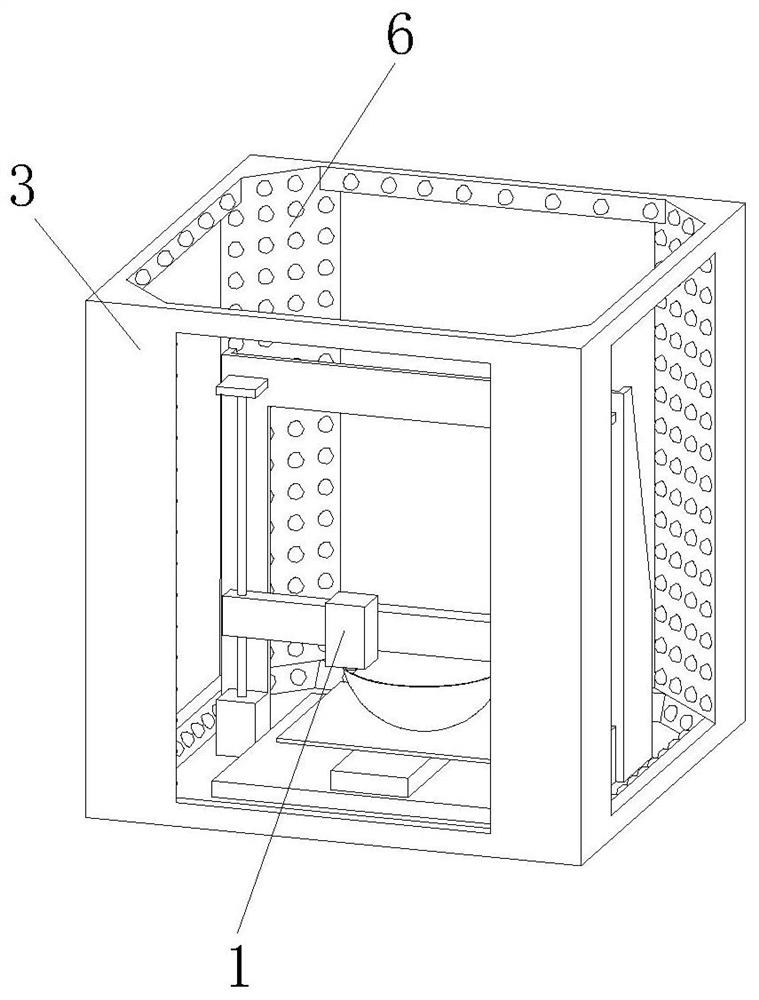

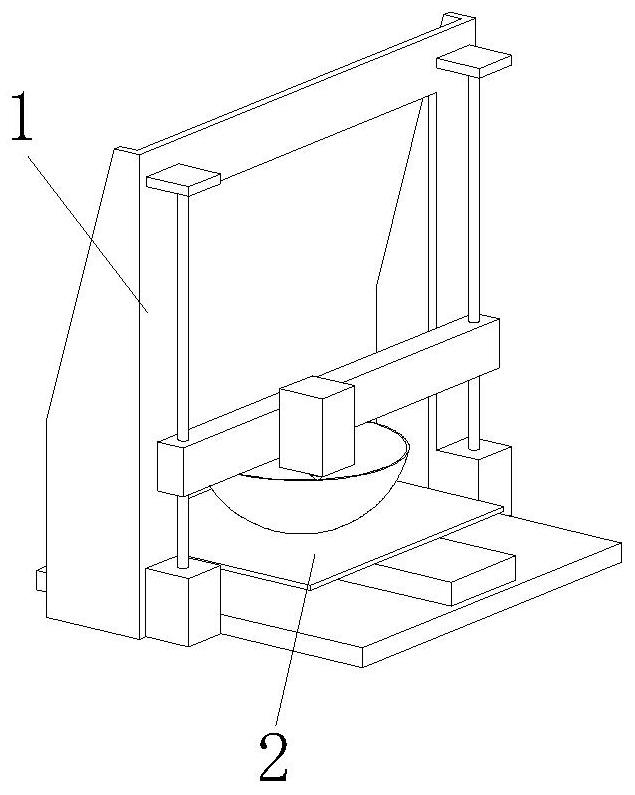

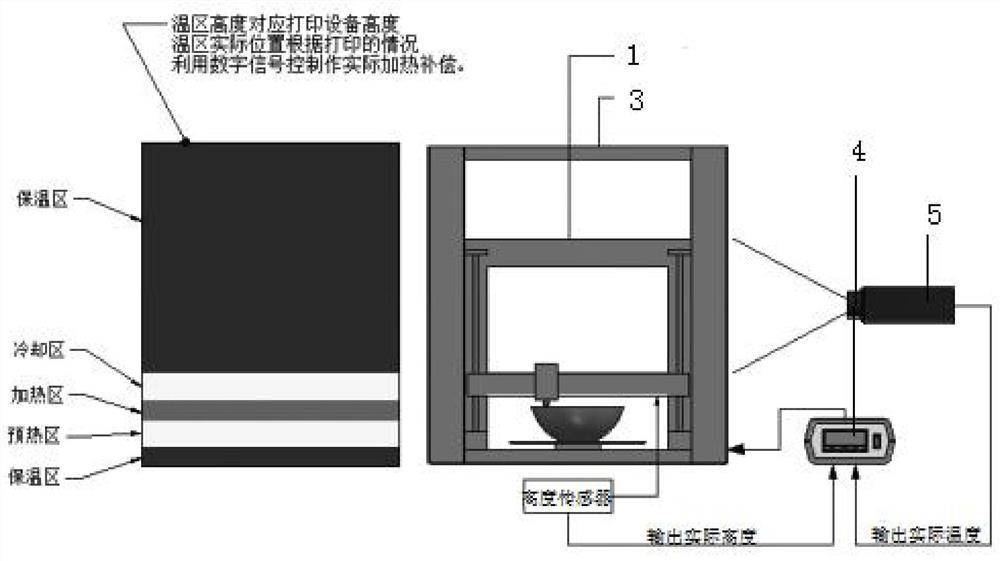

[0026] refer to Figure 1 to Figure 1 0 shows an auxiliary heating device for a 3D printer, including a three-dimensional printing device 1 and a lifting platform 2 arranged on the three-dimensional printing device 1 for carrying workpieces, and also includes a working platform 3, a programmable numerical control heating controller 4 and an infrared The thermal imager 5, the infrared thermal imaging lens of the infrared thermal imager 5 faces the three-dimensional printing device 1 and is used to detect the temperature change of the workpiece, the programmable numerical control heating controller 4 and the infrared thermal imager 5 are all arranged on the working platform 3 On the side, the working platform 3 has a rectangular parallelepiped frame structure and is made of high-temperature-resistant materials. The th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com