Baffle-type cooling bench for shunting and air cooling treatment

A cooling table and baffle-type technology, which is applied in the field of baffle-type shunt air-cooling treatment cooling table, can solve the problems of high wind speed around and uneven air output from the cooling frame, and achieve uniform air output and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

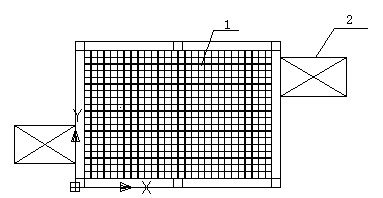

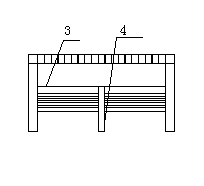

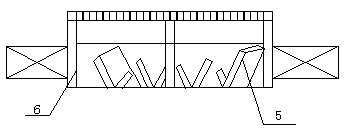

[0013] Embodiment: The structure of the baffle type split flow air cooling treatment cooling platform is shown in the appendix figure 1 , 2 And 3, mainly comprise cooling platform, its main improvement is to be respectively provided with a blower fan 2 diagonally on both sides of cooling platform material frame 6, is provided with air curtain 3 and some step type windshields 5 in the air channel under cooling platform 1, the middle The position is provided with dividing plate 4.

[0014] In the embodiment, the cooling table 1 is a grid structure.

[0015] When the embodiment works, the workpiece is placed on the cooling table 1 for air cooling, the fan 2 is placed at both ends of the cooling table, the air duct is separated from the middle by a partition 4, and each fan controls the air volume on one side; The channel passes through the windshield 5 to realize turning and diversion, and then evenly diverts the flow through the air curtain 3, and finally realizes uniform heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com