Method, device and system for processing handle signals

A handle and signal technology, applied in the field of control, can solve problems such as poor system stability and inability to meet operation control, and achieve the effect of improving fretting and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

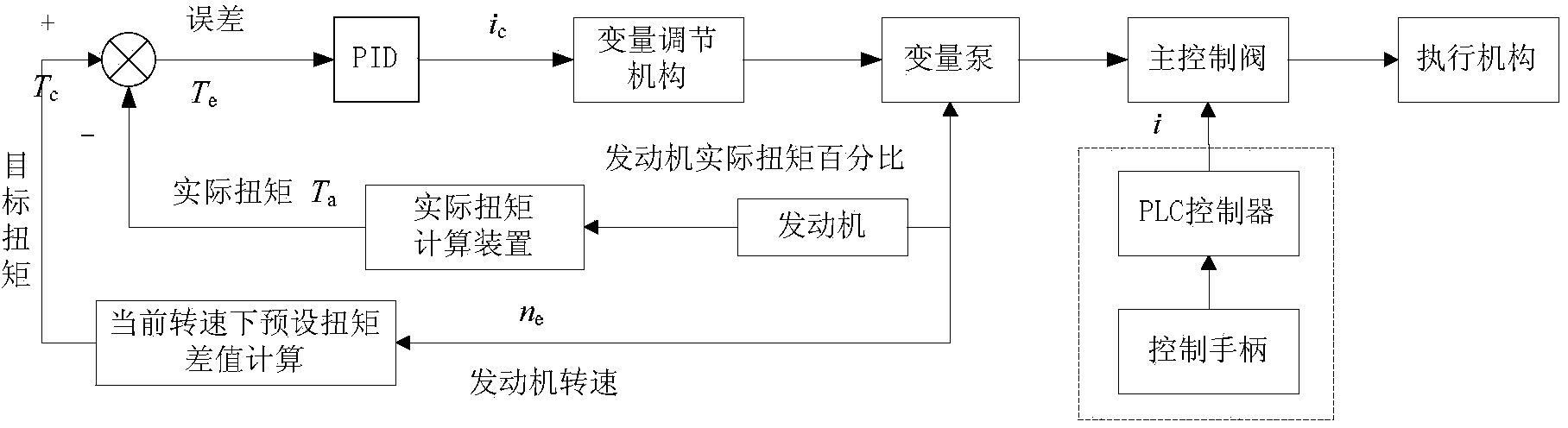

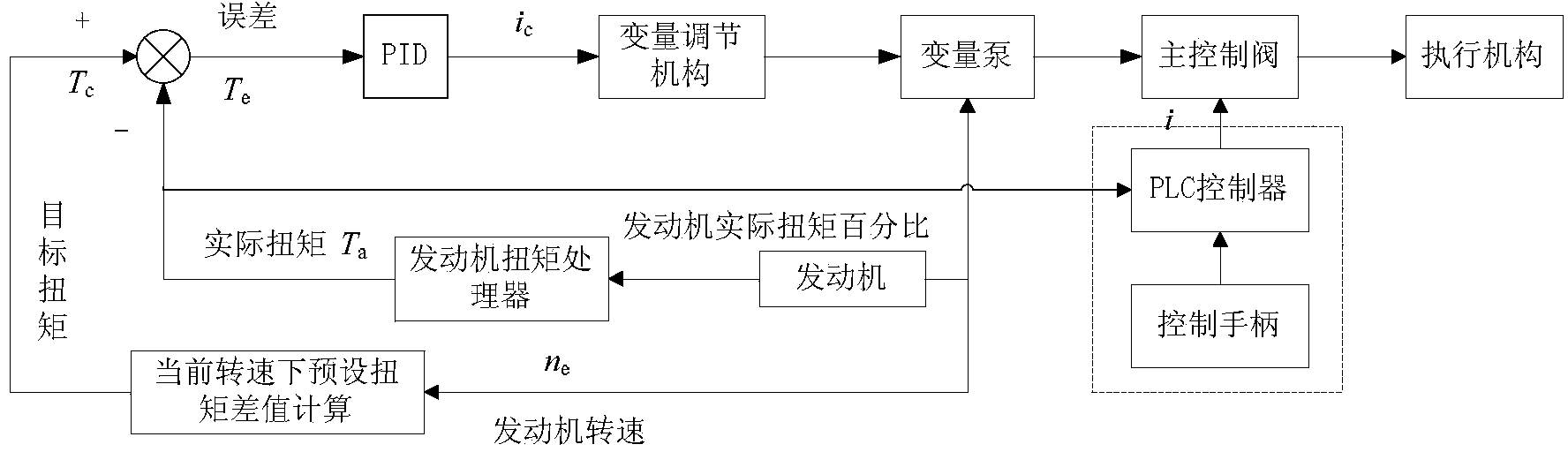

[0040] image 3 is a schematic structural diagram of a handle signal processing system according to an embodiment of the present invention. Such as image 3 As shown, the system includes: an engine; an engine torque processor, electrically connected to the engine, for generating and outputting the actual torque of the engine, in this embodiment, the engine torque processor can be an actual torque calculation device; a control handle, It is used to issue handle control instructions, and obtain the handle angle analog input value of the control handle according to the handle control instructions; the controller (such as a programmable logic controller (Programmable Logic Controller, referred to as PLC)), is set in the engine torque processor and Between the control handles, it is used to receive the actual torque of the engine and the handle angle analog input value of the control handle, and then determine the preset step length setting value of the controller according to the...

Embodiment 2

[0058] Figure 6 is a flowchart of a handle signal processing method according to an embodiment of the present invention, Figure 7 is another flow chart of the handle signal processing method according to the embodiment of the present invention.

[0059] Such as Figure 6 The method shown includes the following steps:

[0060] Step S10, receiving the actual torque of the engine and the handle angle analog input value of the control handle.

[0061] Step S20, determining a preset step length setting value of the controller according to the received actual torque.

[0062] Step S30, detecting the change value of the handle angle analog input value in each control cycle.

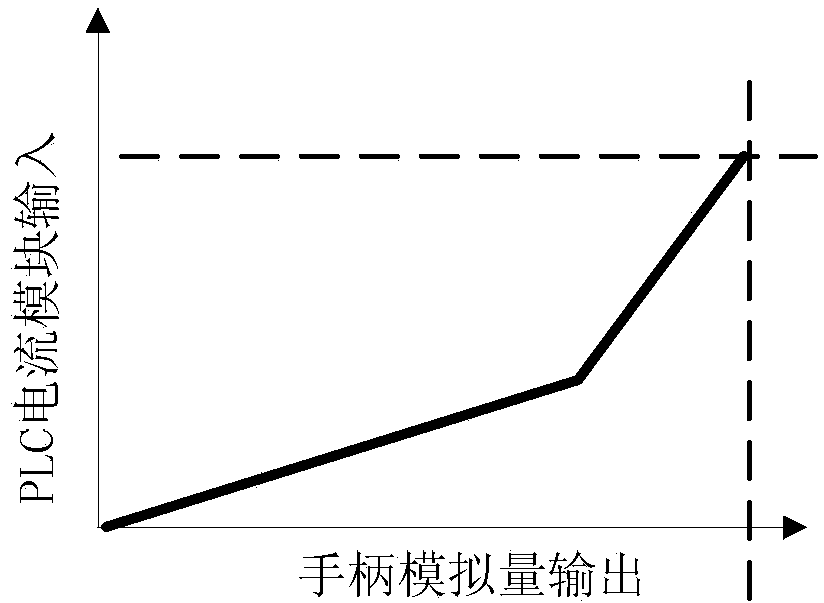

[0063] In step S40, the analog output value of the handle is determined by comparing the change value of the input value of the handle angle analog value with the set value of the step length.

[0064] In this embodiment, after the controller receives the handle angle analog input value of the control han...

Embodiment 3

[0094] Figure 8 is a schematic structural diagram of a handle signal processing device according to an embodiment of the present invention. Figure 9 is another structural schematic diagram of a handle signal processing device according to an embodiment of the present invention. Such as Figure 8 As shown, the device includes: a receiving module 10, which is used to receive the actual torque of the engine and the handle angle analog input value of the control handle; a determination module 30, which is used to determine the step size setting of the controller according to the received actual torque value; the detection module 50 is used to detect the change value of the handle angle analog input value in each control cycle; the processing module 70 is used to compare the change value of the handle angle analog input value with the step size setting value to Determines the handle analog output.

[0095] Through the combined effect of the above modules: after the receiving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com