Automatic routing inspection system for chemical engineering equipment

A technology for automatic inspection and chemical equipment, applied in the direction of registering/instructing the work of machines, instruments, registration/instruction, etc., it can solve the problem that the inspectors are easily paralyzed, the implementation of inspections, the situation in place cannot be accurately grasped, and the safety consequences and other problems, to achieve the effect of improving the standard and scientific management level, promoting the overall inspection work, and avoiding paralysis of the mind.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are provided to specifically describe the present invention. It is necessary to point out that the following examples are only used to further illustrate the present invention, and can not be interpreted as limiting the protection scope of the present invention. Those skilled in the art according to the present invention SUMMARY OF THE INVENTION Some non-essential improvements and adjustments made to the present invention still belong to the protection scope of the present invention.

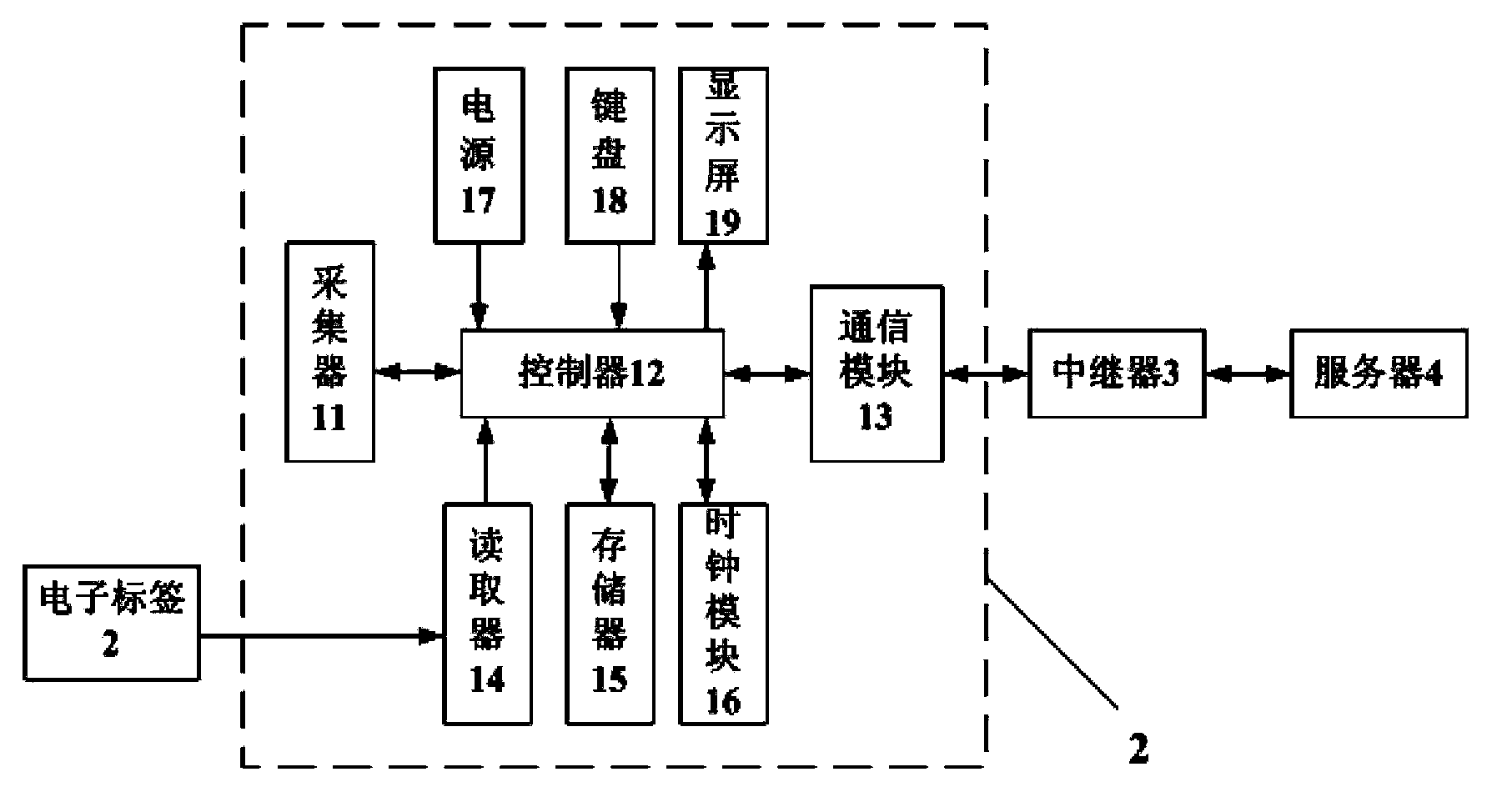

[0026] Such as figure 1 As shown, an automatic inspection system for chemical equipment includes an inspection instrument 1 and an electronic label 2 of the equipment, and the inspection instrument 1 communicates with the server 4 of the management center through a wireless network and a repeater 3 Inspection system; the inspection instrument 1 includes a display screen 19 and a keyboard 18, and the output ends of the keyboard 18 and the power supply 17 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com