Full-automatic cleaning machine

A fully automatic cleaning and cleaning box technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as difficulty in thorough cleaning and reduced cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

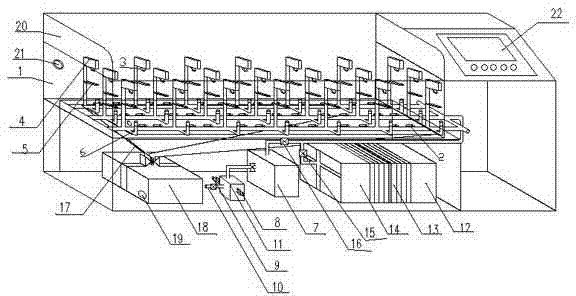

[0031] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

[0032]The fully automatic cleaning machine of the present invention includes a cleaning box 1, which is provided with a water inlet hole and a drainage hole. In this embodiment, the water inlet hole is arranged on the side wall of the cleaning box 1, and the water drainage hole It is arranged at the bottom of the cleaning box 1; the lower rotating nozzle 6 is arranged in the cleaning box 1 and communicated with the water inlet hole through a pipeline, and the setting method and number of the lower rotating nozzle are not unique. In this embodiment, a plurality of the lower rotary spray heads 6 are arranged along the same horizontal plane direction and are connected to each other through pipelines. There are 21 lower rotary spray heads 6 arranged in the cleaning tank 1 in 3 rows and 7 columns along the horizontal plane direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com