Pneumatic and automatic feeder for label laser marking

An automatic feeding and labeling technology, applied in typewriters, printing devices, printing, etc., can solve the problems of not being able to realize automatic control of feeding and marking, and achieve the effects of saving labor costs, ensuring stability, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

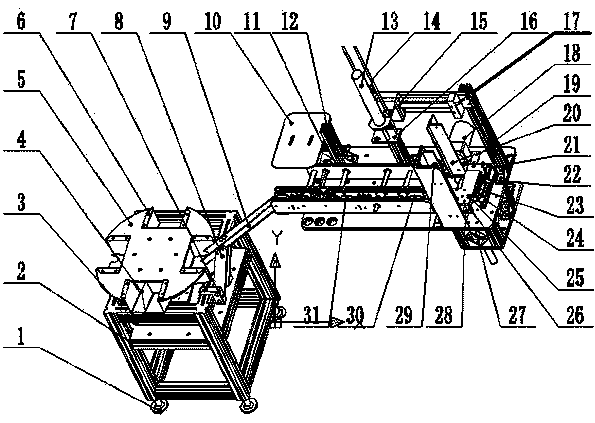

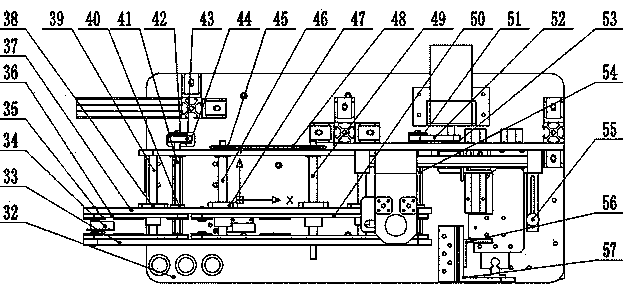

[0019] The automatic loading and unloading machine for laser marking of signs includes an adjustable hopper for placing signs, a conveyor belt for transporting signs and a device for connecting signs.

[0020] The automatic coding machine adopts the common control of pneumatic and electric. The signs to be coded are placed in the hopper. The hopper bottom plate 2 can be moved up and down along the shaft support rail under the push of the turbine worm elevator 27, and the entire sliding table can be moved along another The horizontal axis support rail moves back and forth.

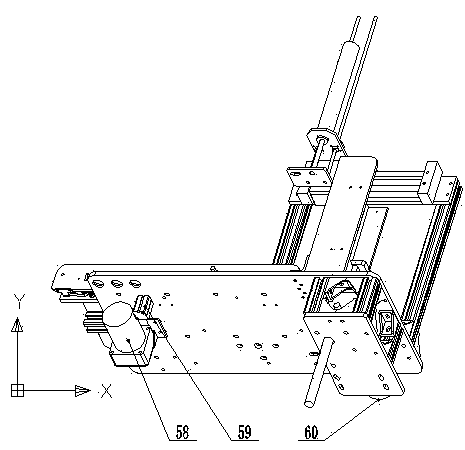

[0021] Before the work starts, the distance between the sliding table and the baffle is manually adjusted according to the size of the sign to ensure the accurate placement of the sign. Start the work, the piston rod of cylinder 1 moves downwards, the fixed vacuum suction cup at the bottom touches the label and sucks the label, the piston rod retracts and moves upward with the label, and stops when it moves to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com