Rotatable engine mounting structure of overhead working vehicle

A technology for rotating engines and aerial work vehicles, applied in power units, vehicle parts, transportation and packaging, etc., can solve problems such as large vibration of engine mounts and platforms, difficult installation, damage to hydraulic pumps and engine accessories, etc. Maintenance performance, easy installation and maintenance, and the effect of solving large vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but they are not used to limit the scope of the present invention.

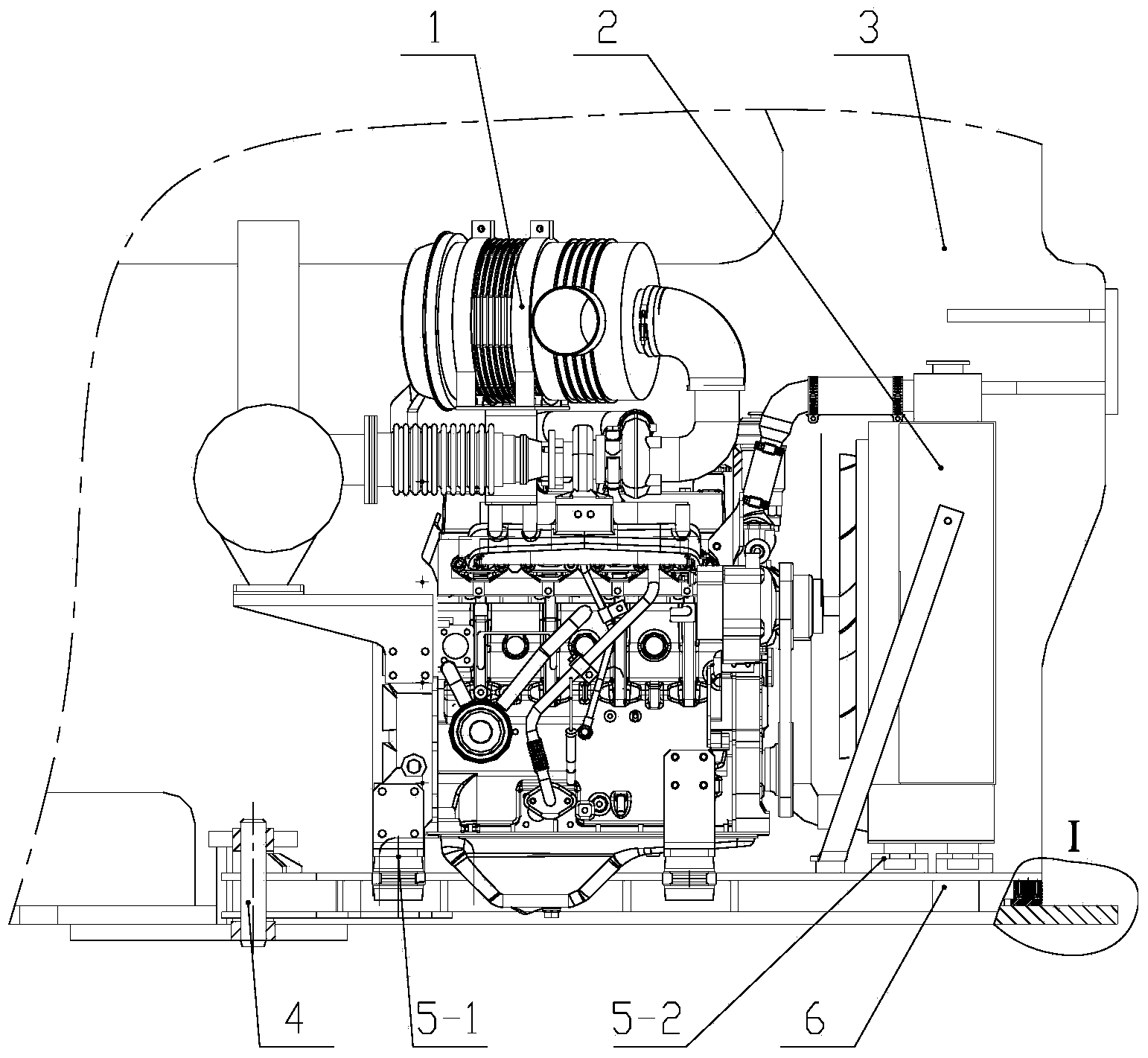

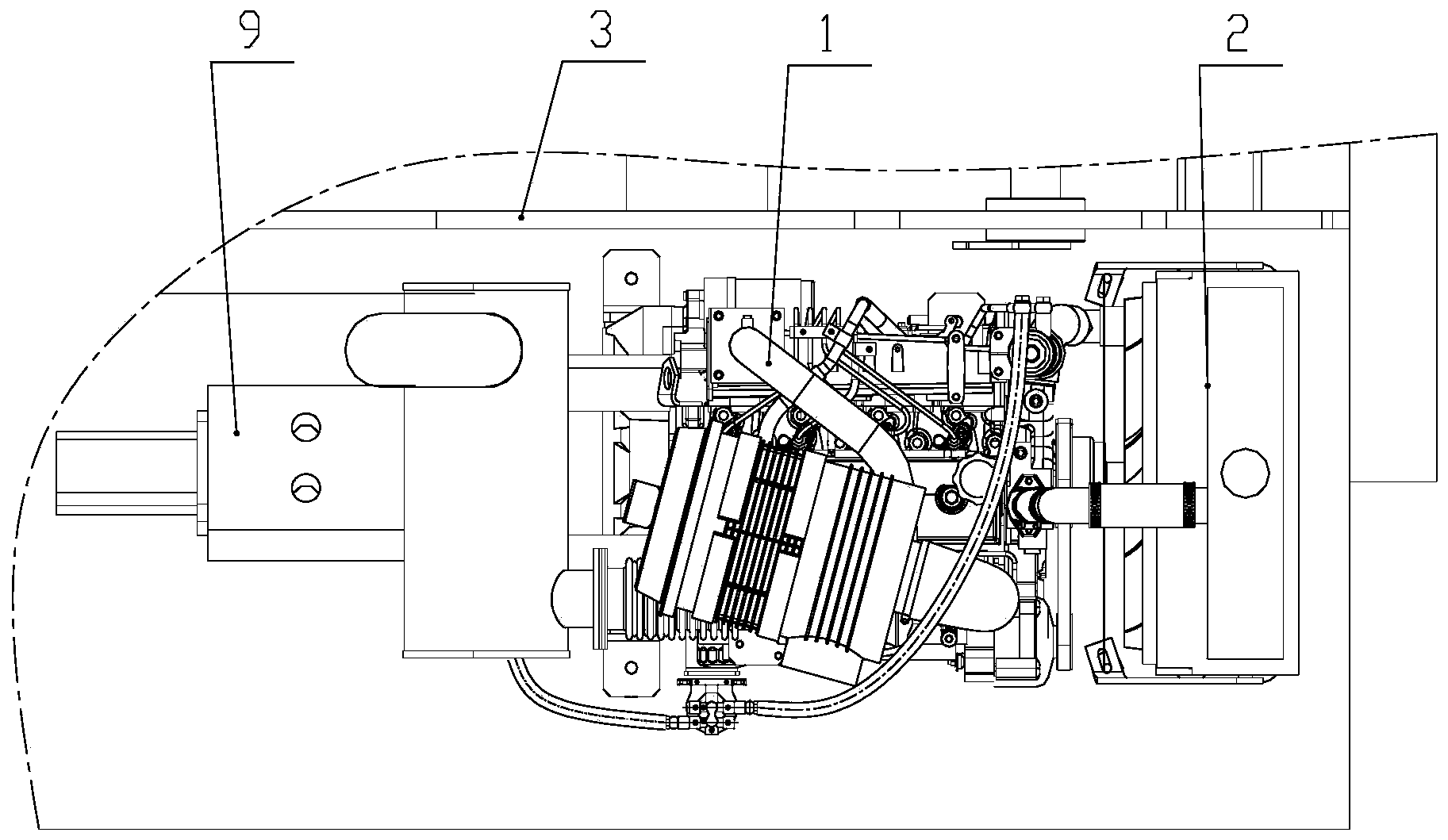

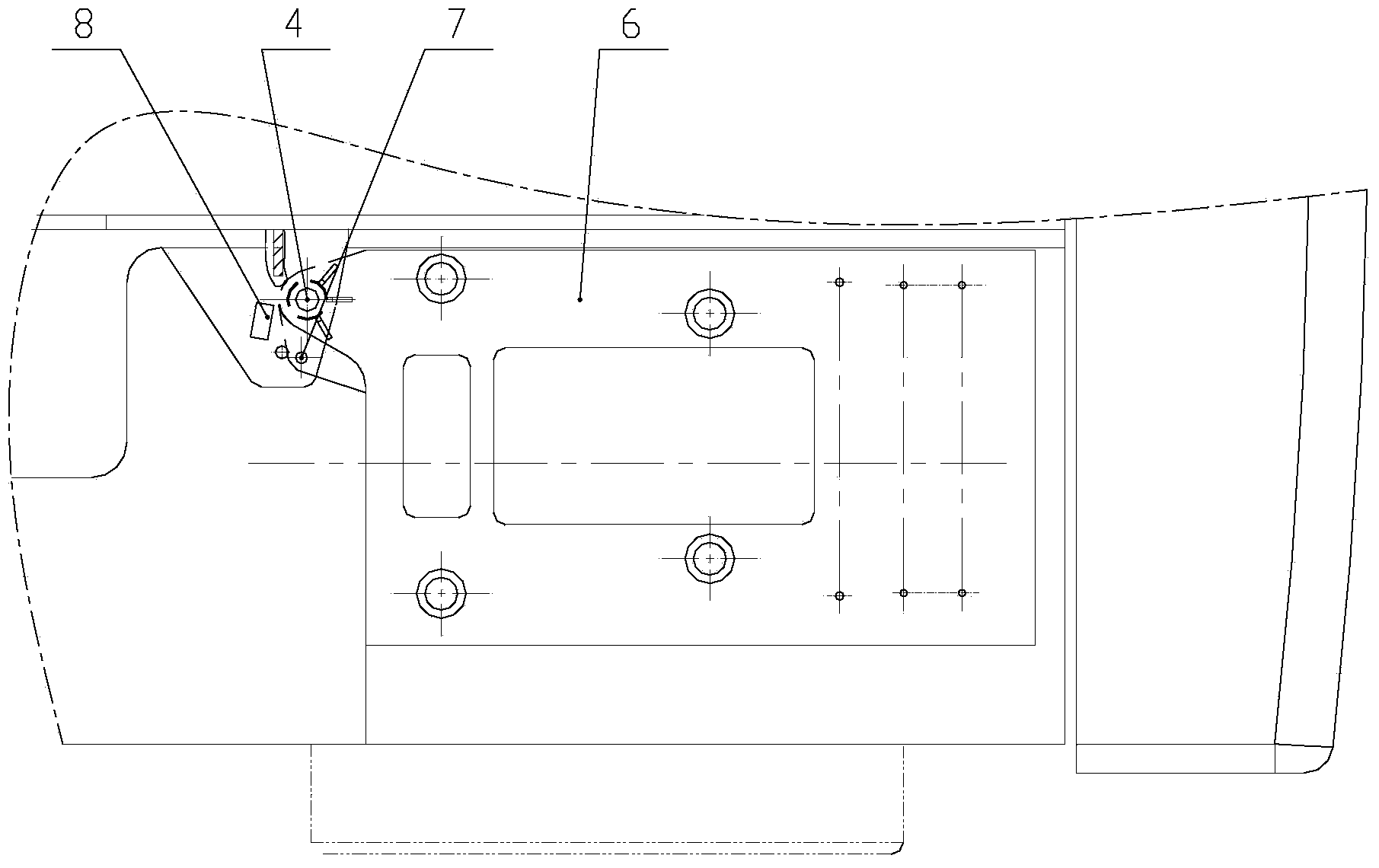

[0030] Such as Figure 1-3 As shown, the engine installation structure of this embodiment includes a fuel engine 1 for aerial work vehicles, a radiator 2, and a hydraulic pump 9 installed on the fuel engine 1 through a coupling. 5-1, 5-2 are connected to the engine mounting base 6, and the engine mounting base 6 is connected to the chassis lug of the platform 3 of the aerial work vehicle through the rotating pin 4, so that the engine mounting base 6 drives all the parts on it The whole can rotate a certain angle around the rotation axis 4. In order to reduce the difficulty of noise control, an oil-free bearing is provided between the rotating pin shaft 4 and the fixed frame, which replaces the rolling bearing commonly used in the prior art, and the processing and installation are also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com