Large model test device simulating deep vertical shaft freezing

A model test device and model test technology, applied in wellbore/well components, earthwork drilling and production, etc., can solve problems such as adverse effects of test results, test failure, and difficulty in realizing high-pressure loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

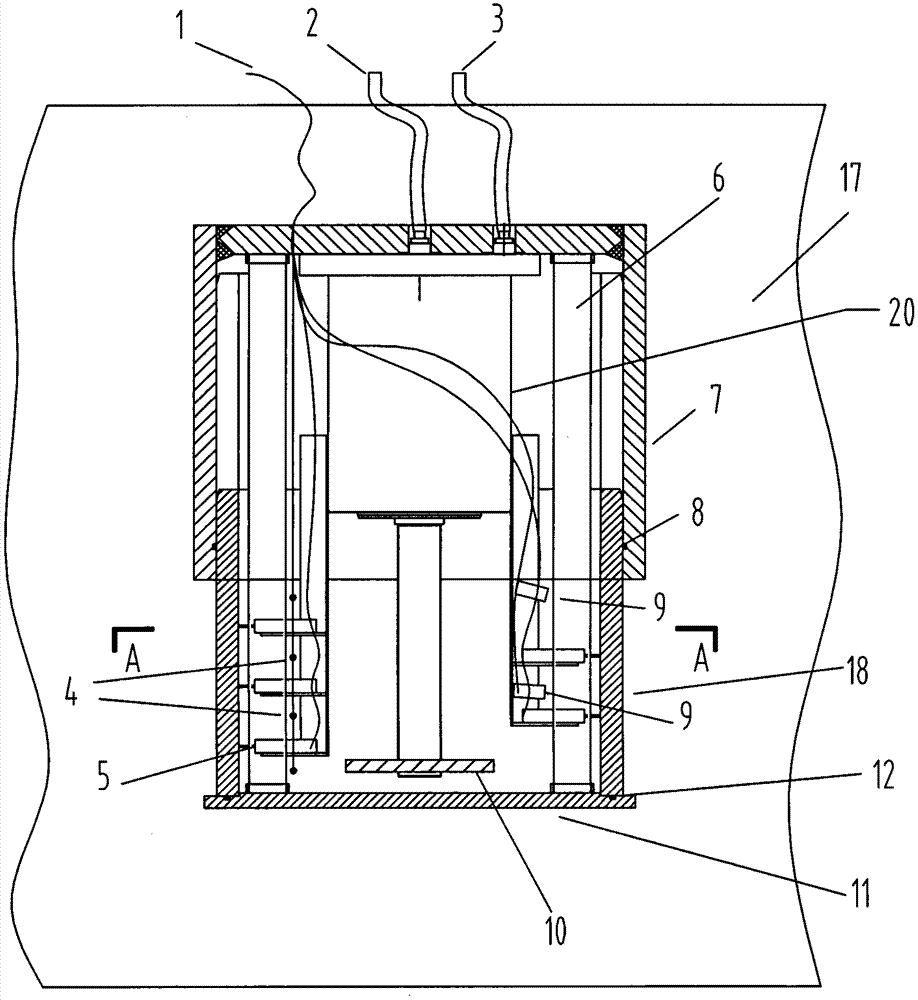

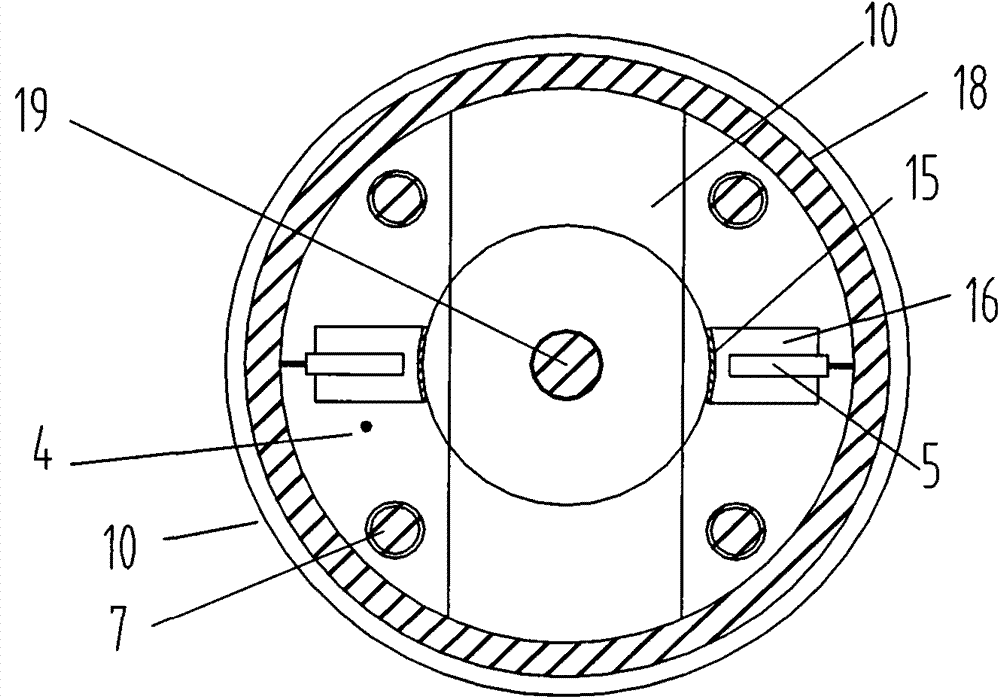

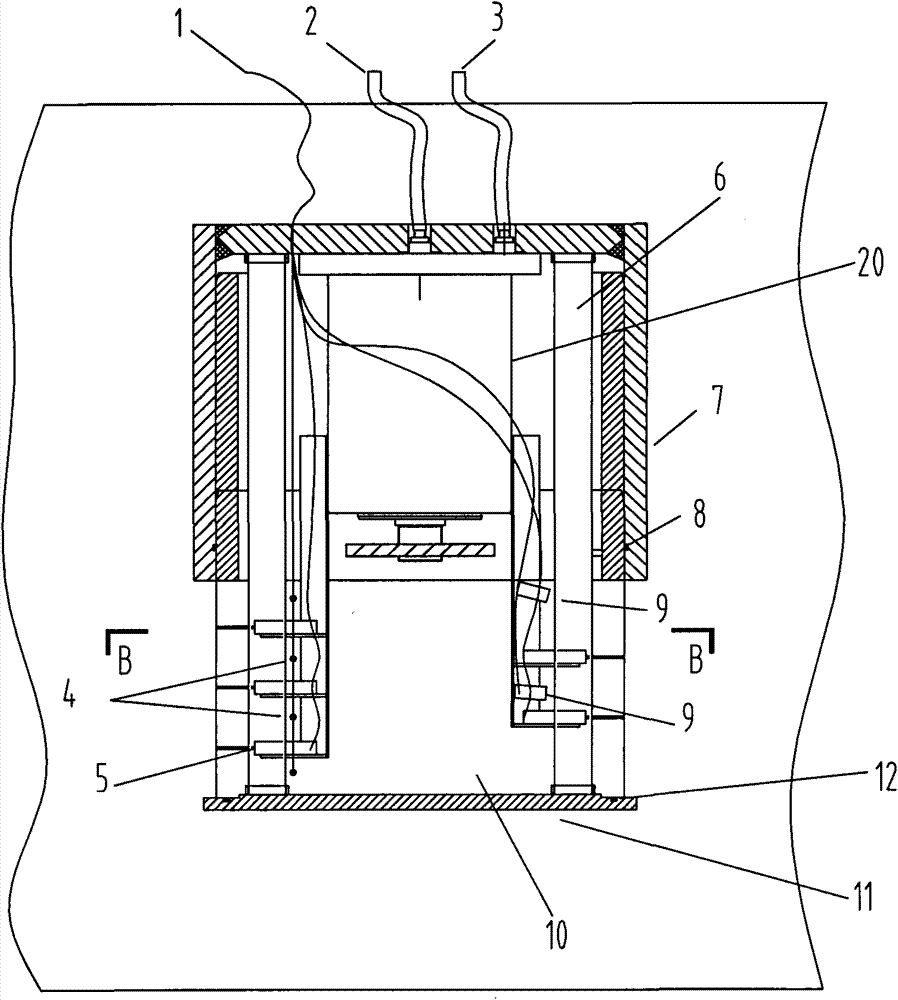

[0027] Such as Figure 5 As shown, the large-scale model test device for simulating deep shaft freezing in this embodiment includes a model test cylinder 100, a mud loading system 200, a hydraulic system 300, an excavation simulation system, a refrigeration system 400, a monitoring system, and a data acquisition and control system 500. The excavation simulation system is located in the soil sample 17, the soil sample 17 is located in the model test cylinder 100, the mud loading system 200, the hydraulic system 300 and the data acquisition and control system 500 are all located outside the model test cylinder 100, and a part of the monitoring system Buried in the soil sample 17, the other part of the monitoring end is located in the excavation simulation system. The output end of the monitoring system is connected to the input end of the data acquisition and control system 500, and the hydraulic system 300 provides hydraulic driving force for the excavation simulation system. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com