Parallelogram mechanism capable of realizing small stroke and long movement distance through oil cylinder

A parallelogram, small stroke technology, used in mining equipment, earthwork drilling, pillars/supports, etc., can solve problems such as low work efficiency, inability to deploy, and many safety hazards, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

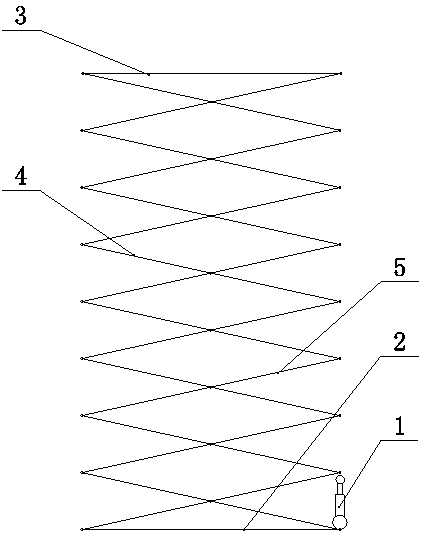

[0017] Such as figure 1 As shown, the present invention uses an oil cylinder to realize a parallelogram mechanism with a small stroke and a large displacement, including a base, a first oil cylinder 1, a first bottom rod 2, a first ejector rod 3, and a plurality of first intermediate rods 4 and a plurality of second rods. The middle rod 5, the first bottom rod 2 and the first push rod 3 are telescopic rods, the first oil cylinder 1 and the first bottom rod 2 are all arranged on the base, and the first oil cylinder 1 is vertically arranged, The first bottom bar 2 is arranged horizontally, the plurality of first intermediate bars 4 are arranged parallel and equidistant in the vertical plane, and the plurality of second intermediate bars 5 are also arranged parallel and equidistant in the vertical plane, so The first intermediate rod 4 and the second intermediate rod 5 are all intersected in pairs, and the intersection position of the first intermediate rod 4 and the second inter...

Embodiment 2

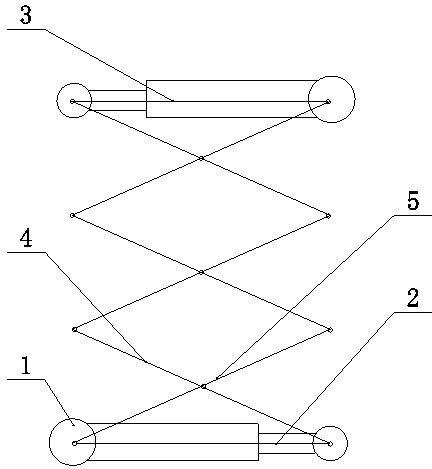

[0019] The number of the first oil cylinder 1 is two, and the two first oil cylinders 1 are horizontally parallel and oppositely arranged, and the cylinder body of one of the first oil cylinders 1 is hinged with the bottom end of the first intermediate rod 4 at the lowest end , the piston rod is hinged with the bottom end of the second intermediate rod 5 at the lowest end, the cylinder body of the other first oil cylinder 1 is hinged with the top end of the first intermediate rod 4 at the top end, and the piston rod is hinged with the top end of the first intermediate rod 5 at the top end The top ends of the second middle rod 5 are hinged together to control the expansion and contraction of the first oil cylinder 1 and adjust the height of the first push rod 3 .

[0020] All the other parts are the same as embodiment one.

Embodiment 3

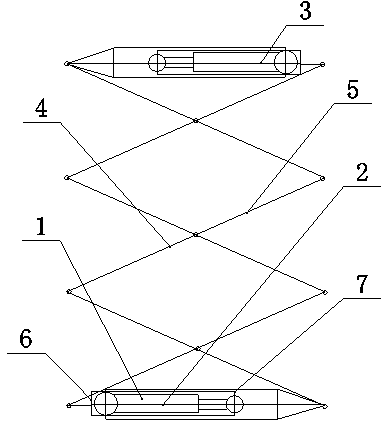

[0022] The piston rod of the first oil cylinder 1 is provided with an inner connecting rod 6, and the cylinder body of the first oil cylinder 1 is provided with an outer connecting rod 7. The inner connecting rod 6 is located inside the outer connecting rod 7, and the inner connecting rod 6 and the outer connecting rod 7 are arranged in parallel, the inner connecting rod 6 and the outer connecting rod 7 can move alternately under the expansion and contraction of the first oil cylinder 1, and one end of the inner connecting rod 6 is hinged to the piston rod of the first oil cylinder 1 Above, the other end of the inner connecting rod 6 is hinged to one end of the second intermediate rod 5, one end of the outer connecting rod 7 is hinged to the cylinder body of the first oil cylinder 1, and the other end of the outer connecting rod 7 is connected to One end of the first intermediate rod 4 is hinged to control the expansion and contraction of the first oil cylinder 1 and adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com