Overhead continuous goods delivering device

A technology of linkage device and cutting device, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of loss, delivery failure, slow speed, etc., achieve high accuracy and prevent drifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

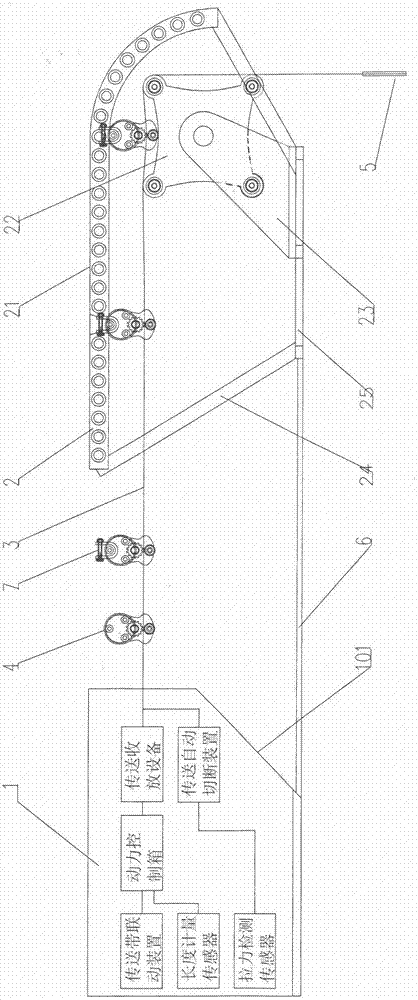

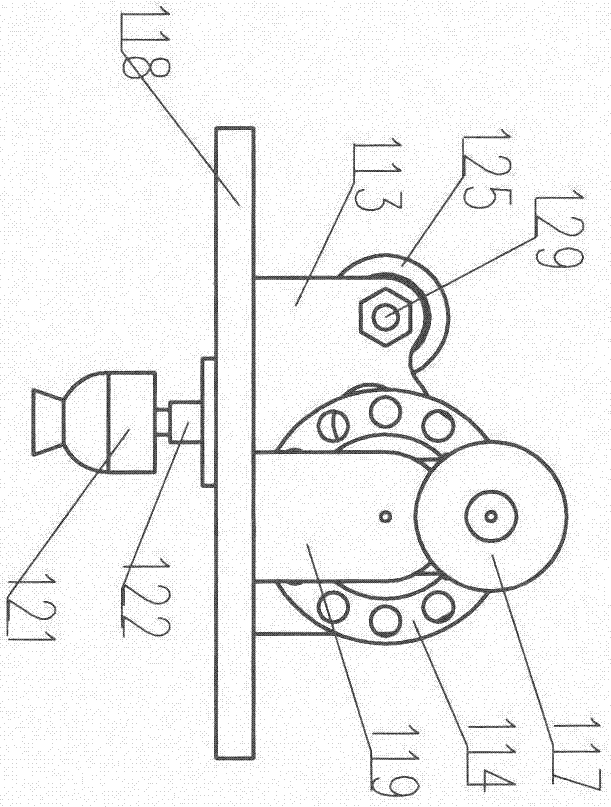

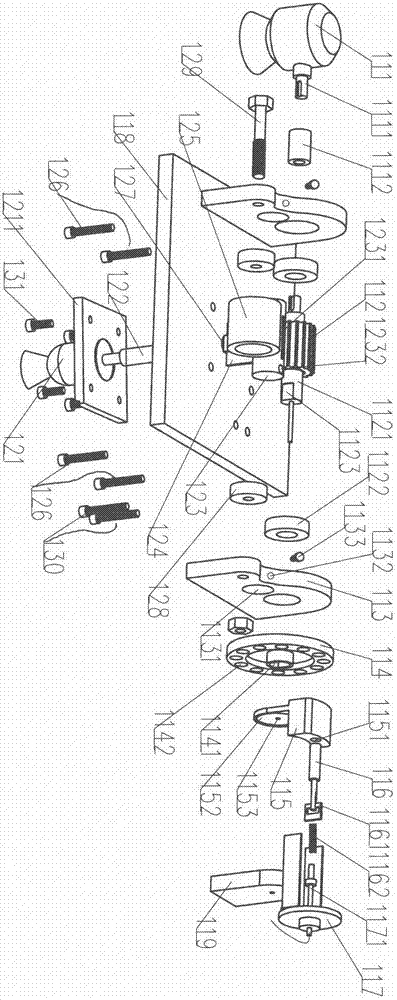

[0021] From attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7It can be seen that the high-altitude continuous throwing device of the present invention is composed of a conveyor belt control unit 1, a material carrying platform 2, a conveyor belt 3, a damper 4, an anchor counterweight 5 and a coupling frame 6, and is characterized in that: the conveyor belt control Unit 1 includes a conveyor belt retractable device, a power control box, a conveyor belt linkage device, a length measurement sensor, a tension detection sensor, a conveyor belt cutting device, and a cabinet 101 for accommodating and installing the components. The conveyor belt retractable device includes a motor, a reducer and The winding reel is driven by the motor through the reducer to extend or retract the conveyor belt 3. There is a "PC" control component installed in the power control box, and the "PC" control component operates under the program set by itself. Integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com