Cylindrical silo top truss platform descending system and control method of cylindrical silo top truss platform descending system

The technology of a truss platform and a control method is applied in the direction of scaffolding supported by a house structure, house structure support, house structure support, etc., which can solve problems such as collision with the inner wall of the warehouse, tilting of the truss platform, deviation, etc., and achieve huge economic benefits and solve The effect of falling demolition construction difficulties, rapid decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

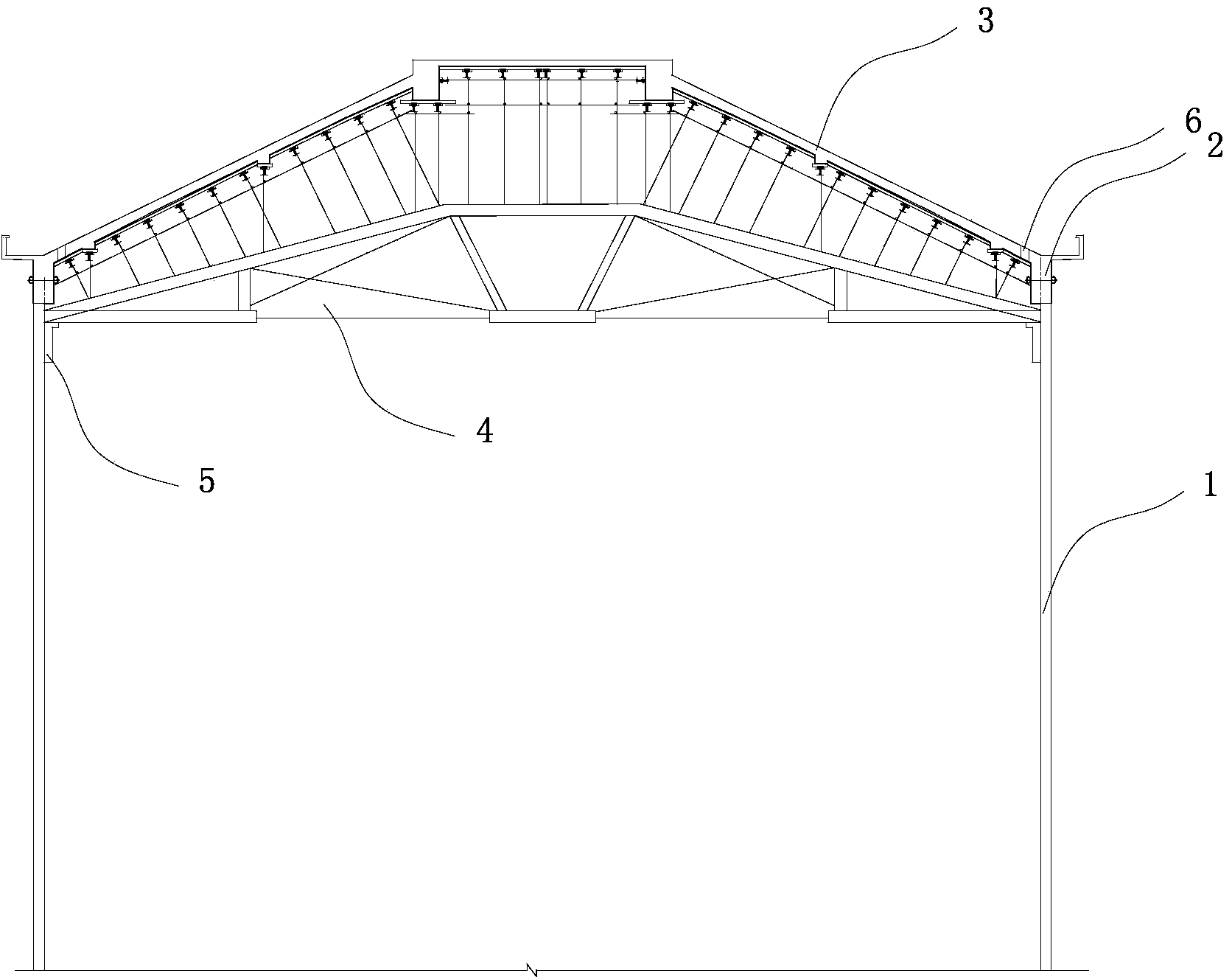

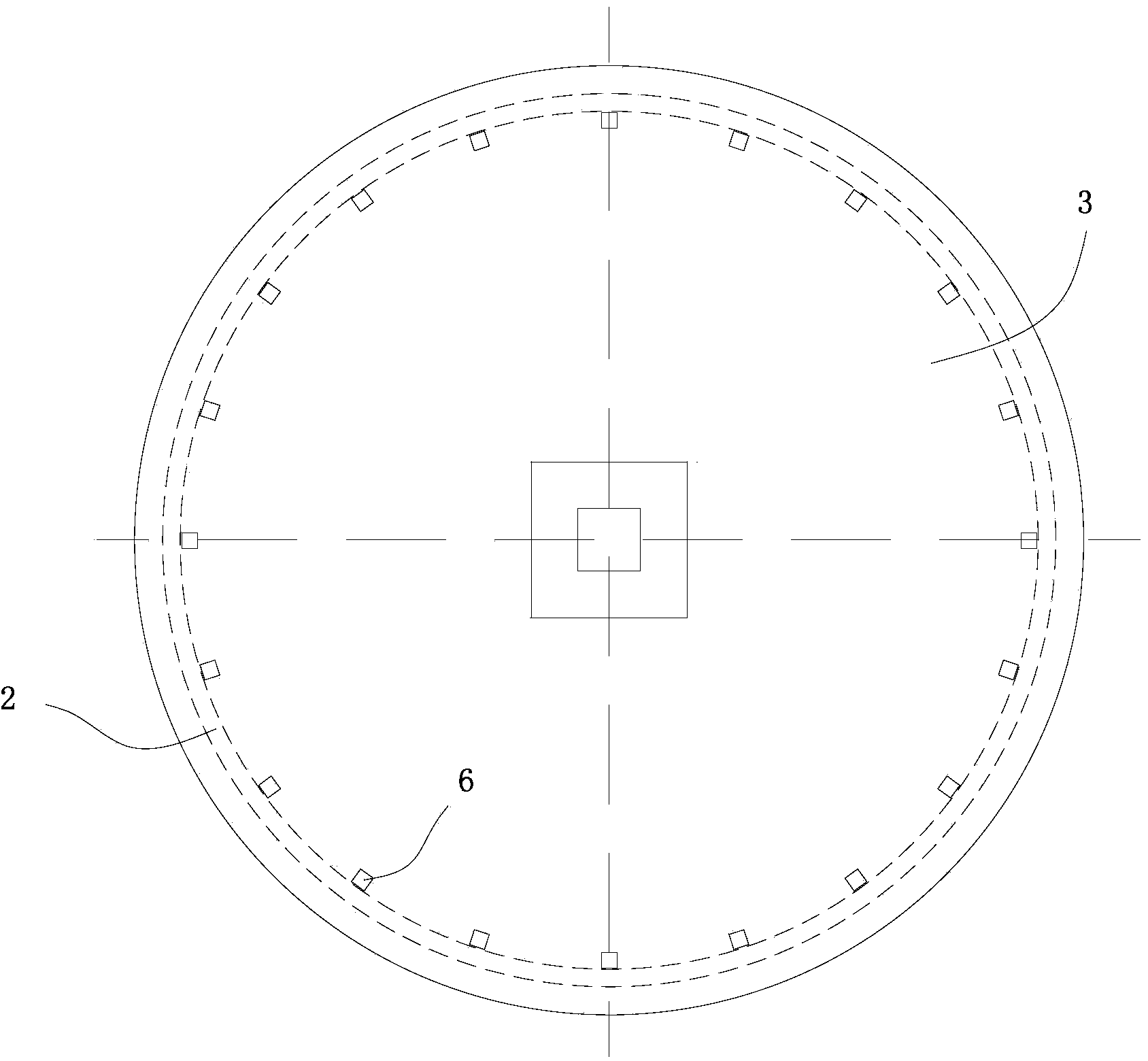

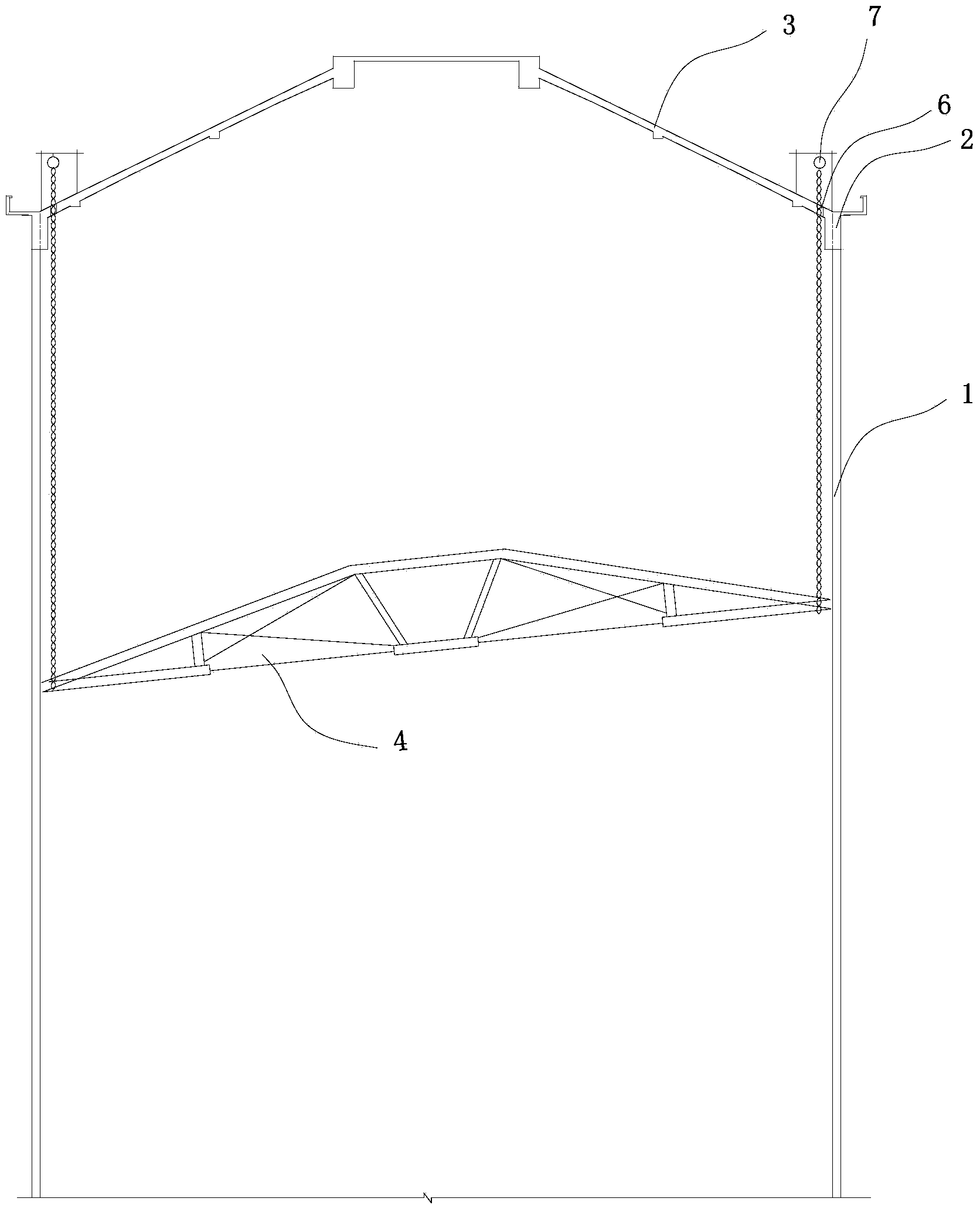

[0034] refer to Figure 4 to Figure 12 , a truss platform lowering system on the roof of a silo according to the present invention, comprising electric chain hoists 7 arranged continuously at intervals along the hoop of the warehouse and a controller for controlling synchronous linkage or independent transfer of each electric chain hoist 7, each chain The end of the chain of the electric hoist 7 passes through the roof of the silo and is connected to the outer edge of the truss platform 4. A space measuring device 8 for measuring the inclination direction and inclination angle of the truss platform 4 during the descent process is provided at the center of the top of the truss platform 4. A laser emitter 9 aligned with the space measuring device 8 is arranged at the bottom center of the silo roof.

[0035] A method for controlling the descent of a silo roof truss platform according to the present invention comprises the following steps:

[0036] (1) A plurality of die-cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com