Electrorheological buffer

A buffer, electrorheological technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as limited adjustment range, fixed stiffness and damping characteristics, and inability to adjust the buffer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

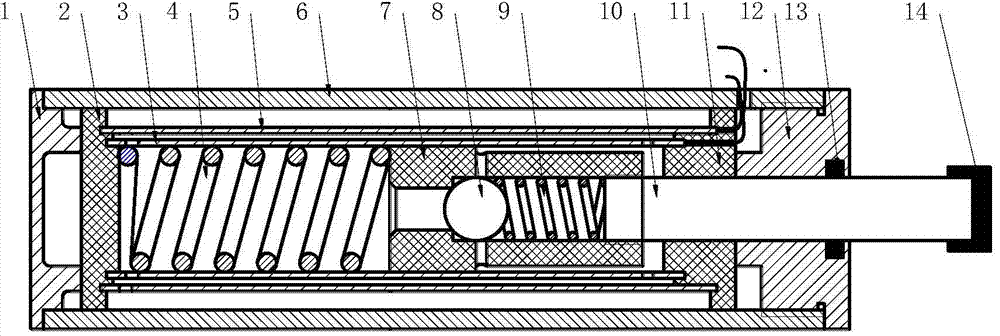

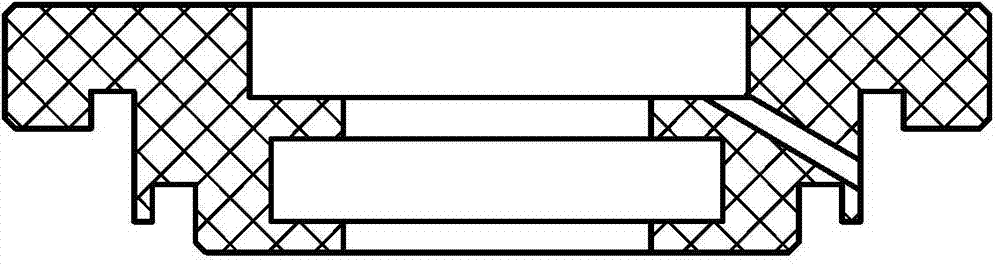

[0014] The present invention is an electrorheological buffer, which mainly includes: rear end cover 1, rear insulating sleeve 2, inner cylinder 3, metal spring 4, middle cylinder 5, outer cylinder 6, piston 7, one-way valve pin 8, one-way valve metal Spring 9, piston rod 10, front insulating sleeve 11, front end cover 12, star seal ring 13 and collision head rubber sleeve 14. by figure 1 For example, when the rubber sleeve 14 of the bumper bumper is subjected to an external impact load, the piston rod 10 of the buffer moves to the left, pushing the piston 7 to compress the metal spring 4, and making the electrorheological fluid in the rodless cavity flow from the left end of the inner cylinder 3 part of the electrorheological fluid flows to the rod chamber through the annular electric field formed by the inner cylinder 3 and the middle cylinder 5, and part of it flows through the fluid hole at the lower left end of the middle cylinder 5 to the annular oil storage formed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com