High/low speed bidirectional damping adjustable mechanical damper

A two-way damping and shock absorber technology, which is applied to shock absorbers, liquid shock absorbers, shock absorbers, etc. Convenient damping characteristics, small changes in external dimensions, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

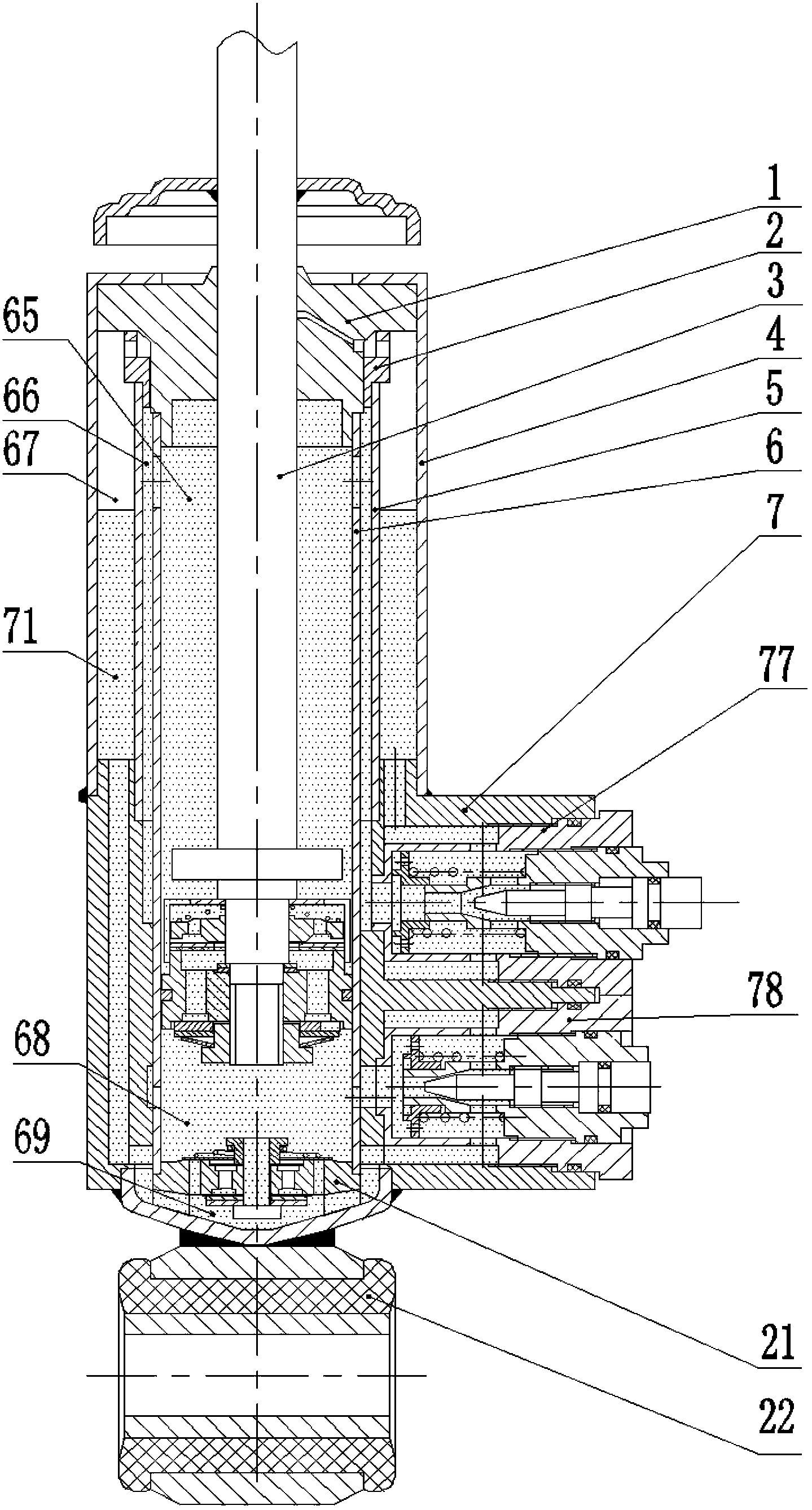

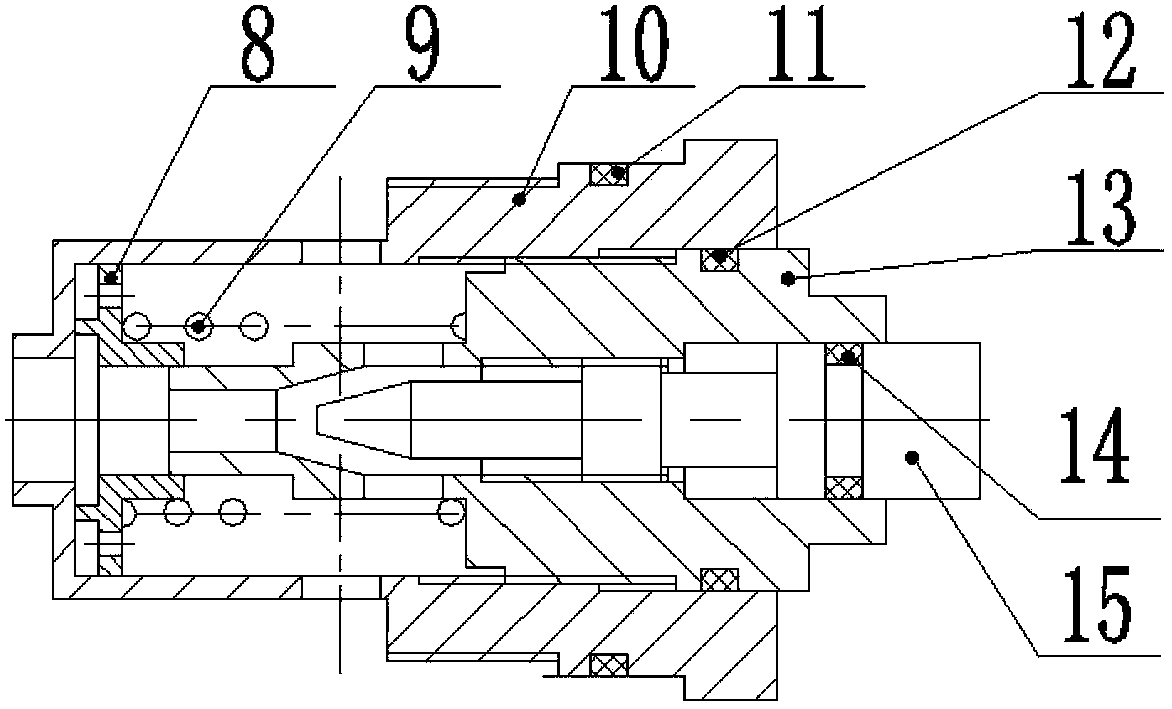

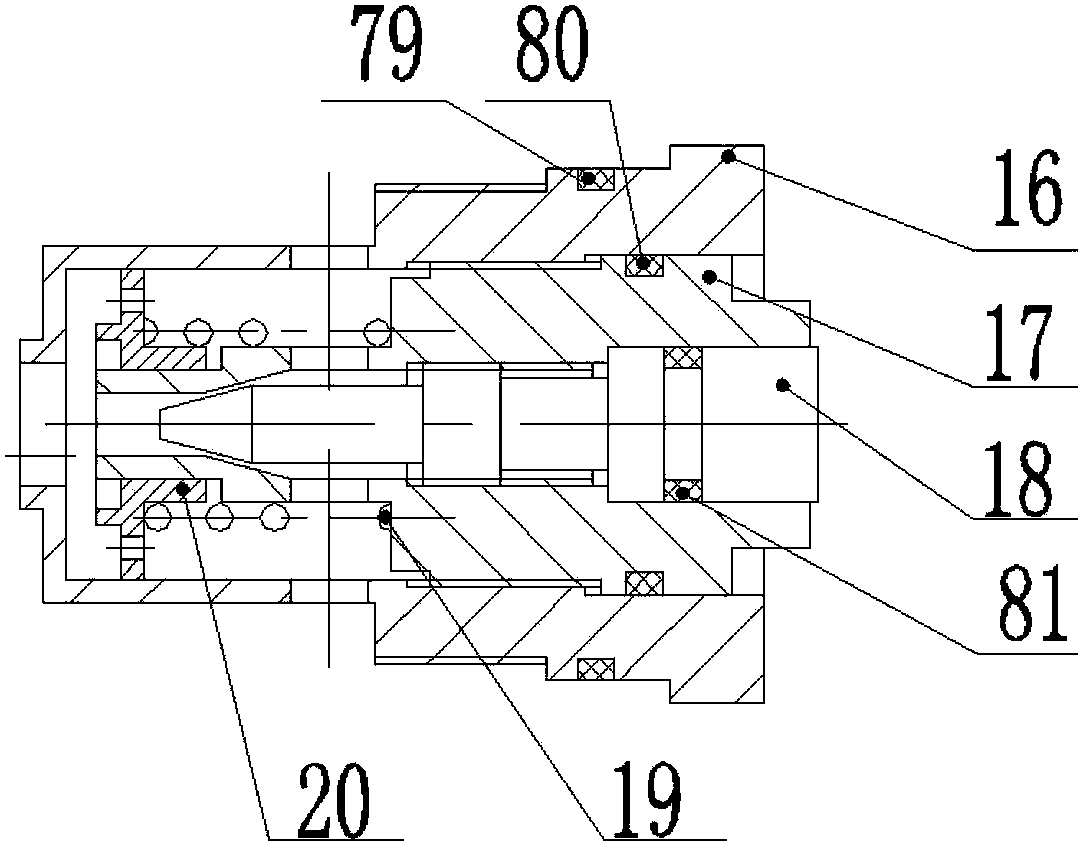

[0038] The present invention is described in detail below in conjunction with accompanying drawing:

[0039] refer to figure 1 , the high-low speed two-way damping adjustable mechanical shock absorber of the present invention includes the original shock absorber piston upstroke limit block 1, the middle cylinder fixing ring 2, the original shock absorber piston assembly 3, the oil storage cylinder 4, the middle Cylinder 5, piston cylinder 6, bypass valve body 7, tension bypass valve 77, compression bypass valve 78, piston cylinder bottom valve assembly 21 and shock absorber lower fixing ear assembly 22; where: tension bypass The valve 77 has the same structure as the compression bypass valve 78 .

[0040] The original shock absorber piston upstroke limiting block 1 is fitted on the piston rod 72 in the original shock absorber piston assembly 3 through its inner hole to form a sliding fit. The cylindrical surface is in contact with the end surface and the inner cylindrical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com