Magnetic flux leakage detecting device for steel pipe and detection method thereof

A magnetic flux leakage detection and steel pipe technology, applied in the direction of material magnetic variables, can solve the problems of prolonging the production cycle, affecting the detection accuracy of steel pipes, increasing production costs, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

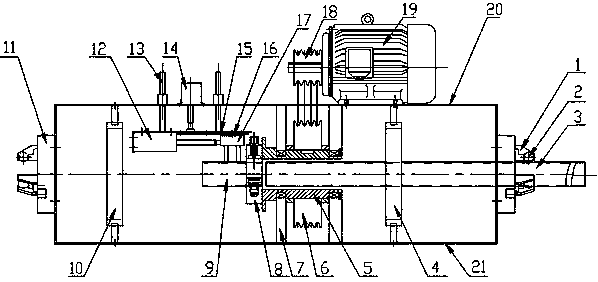

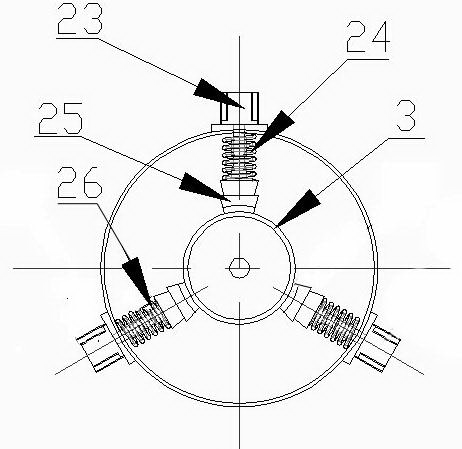

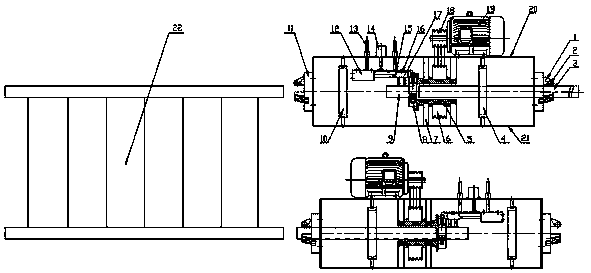

[0030] Steel pipe flux leakage detection device provided by the present invention is as figure 1 As shown, including the detection box, the two ends of the detection box are respectively equipped with an inlet three-jaw chuck 1 and an outlet three-jaw chuck 11, and the upper plate 20 and the lower plate 21 of the detection box are sequentially equipped with The first magnetizing coil 4, the hollow rotating body 5 and the second magnetizing coil 10, the hollow rotating body 5 is installed on the upper plate 20 by the bracket 7, the probe frame 8 with the induction probe group is installed on it, the hollow rotating body 5 is rotating Under the action of the driving device, the probe frame 8 is driven to rotate around the through hole of the steel pipe, and the center of each device is provided with a through hole. The induction probe group includes a number of induction prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com