Non-electric full-automatic gas-liquid rotary spraying fire extinguishing device for military communication shelter

A fire extinguishing device, fully automatic technology, applied in fire rescue and other directions, can solve problems such as being easily affected by water temperature, increasing workload, valve port closing, etc., achieving remarkable fire extinguishing effect and enhanced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

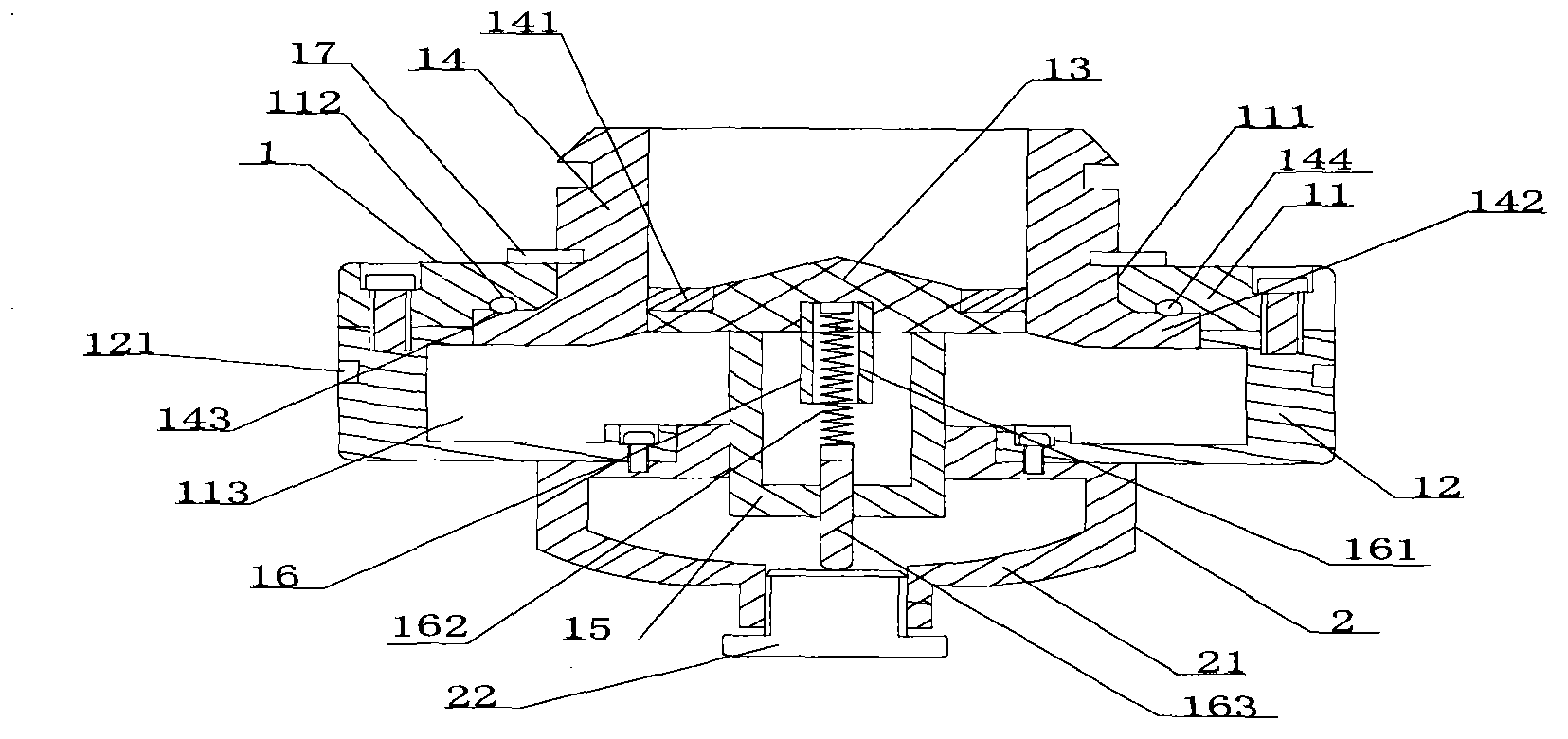

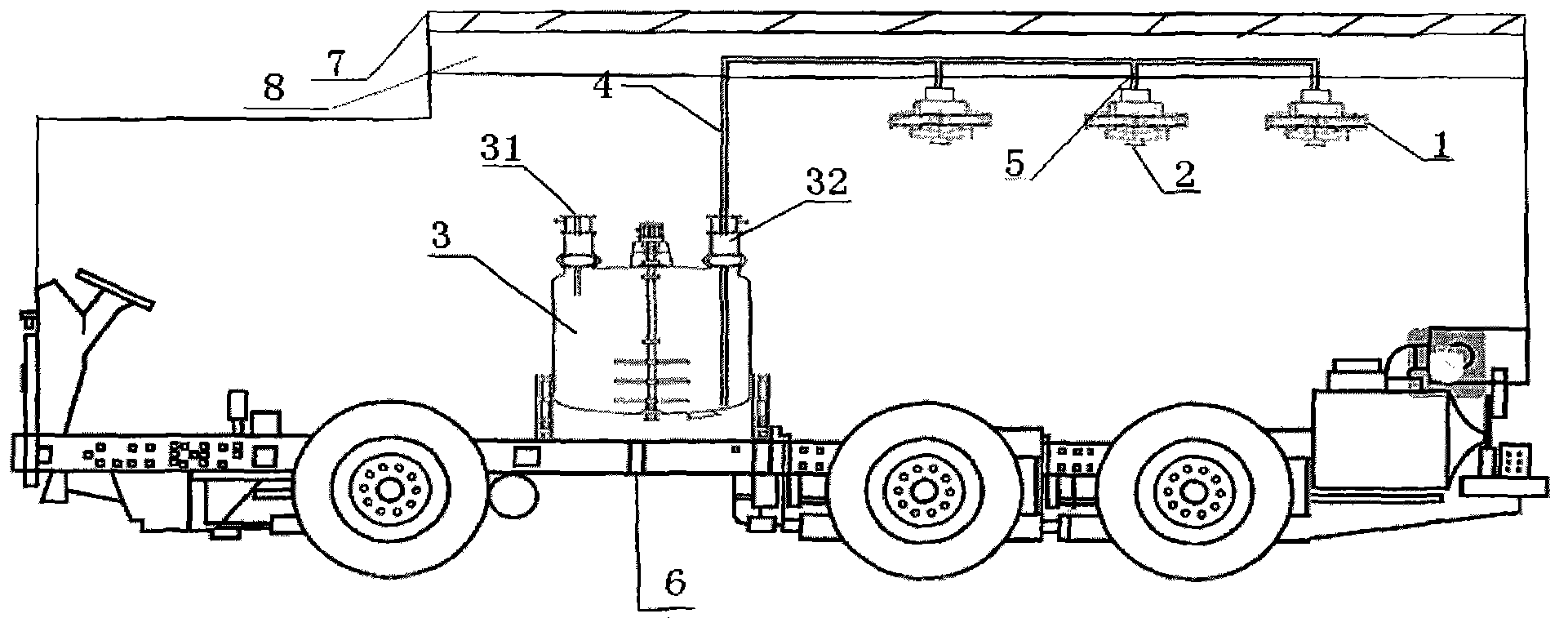

[0017] Such as figure 1 As shown, a non-electric fully automatic gas-liquid rotary spray fire extinguishing device for a military communication shelter, which includes a rotary spray mechanism 1 and a bracket mechanism 2, and the bottom of the rotary spray mechanism 1 is fixedly equipped with a bracket mechanism 2; specifically:

[0018] The rotary spray mechanism 1 includes an upper end cover 11, a lower end cover 12, a flow divider 13, an interface 14, a temperature insulating sleeve 15 and a driving assembly 16; the upper end cover 11 is provided with a through hole 111, and its bottom is provided with an annular groove 112, and the upper end cover 11 and the lower end cover 12 are screwed together to form a material cavity 113; the interface 14 is installed in the through hole 111, and the interface 14 is snapped together with the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com