A double-layer filter tube

A filter tube, double-layer technology, which is applied in the field of nuclear fuel original production, can solve the problems of high burden on the exhaust system, reduce filtration pressure drop, unfavorable stable production operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A kind of double-layer filter tube provided by the present invention is introduced below in conjunction with accompanying drawing and embodiment:

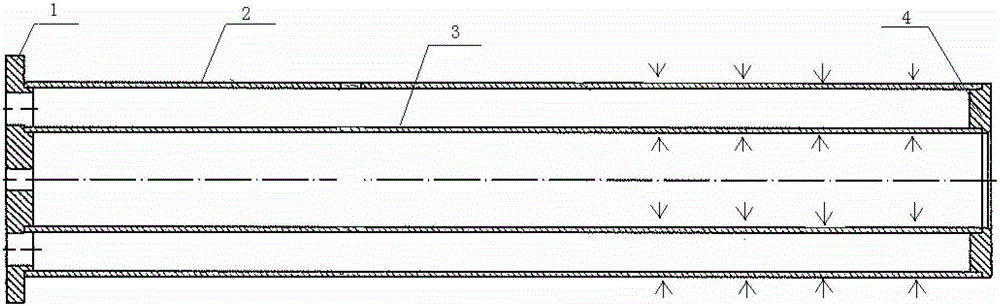

[0019] like figure 2 As shown, a double-layer filter tube includes a mounting flange 1, an outer tube 2, an inner tube 3 and a ring plate 4, wherein the mounting flange 1 is a double-cylindrical boss structure, and the inner tube 3 Set on the outside of the inner boss and welded with the inner boss, the outer tube 2 is set on the outside of the outer boss and welded with the outer boss; the ring plate 4 is a single ring boss structure, and the inner tube 3 is welded On the inner circle of the boss, the outer tube 2 is welded on the outer circle of the boss.

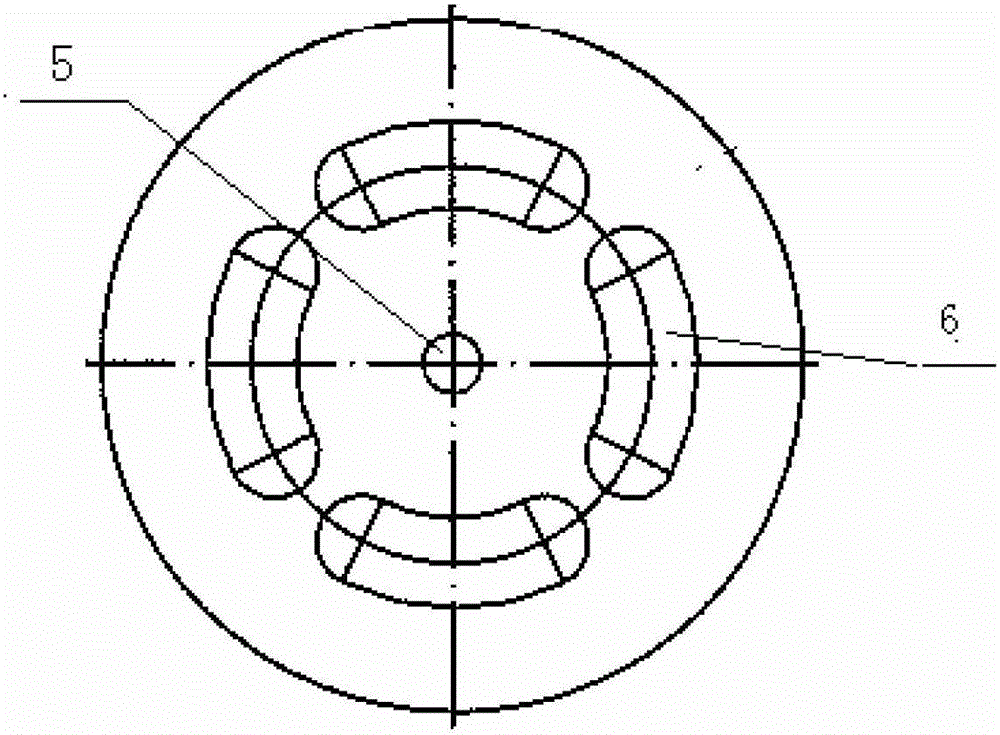

[0020] like image 3 As shown, the mounting flange 1 is Monel alloy, and the upper annular array has four waist-shaped vent holes 6, and the four vent holes 6 communicate with the interlayer of the inner tube 3 and the outer tube 2, and the center of the mounting fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com