Dust removal device and method for oil and gas containing dust

A dust removal device, oil and gas technology, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of low dust particle collection efficiency, cumbersome follow-up treatment, increased pressure drop inside and outside the membrane tube, etc., to reduce oil and gas Effect of Dust Load and Tar Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

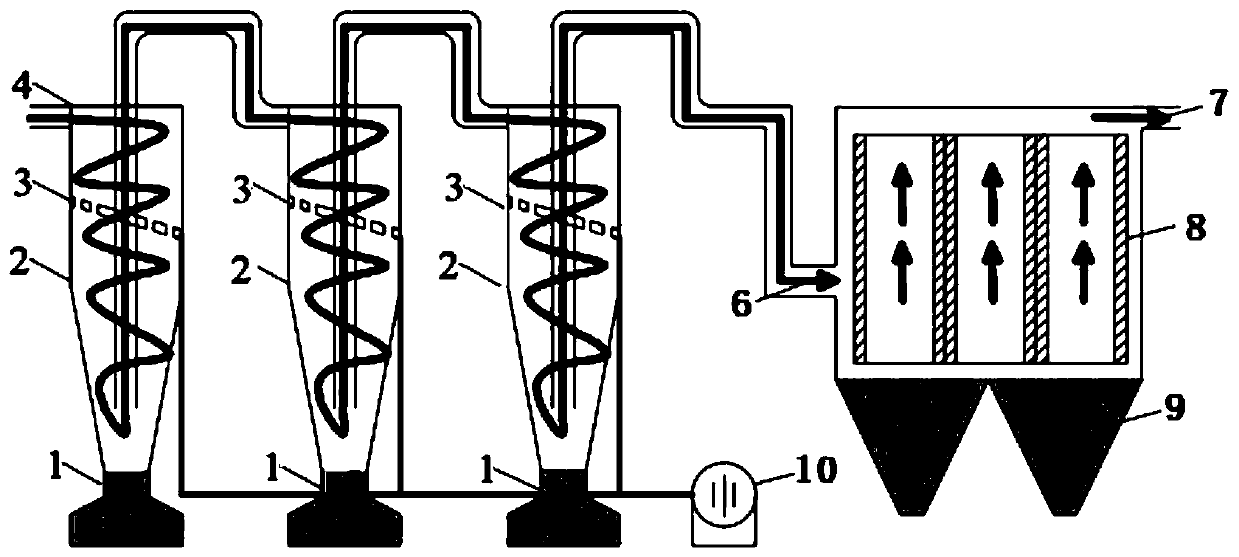

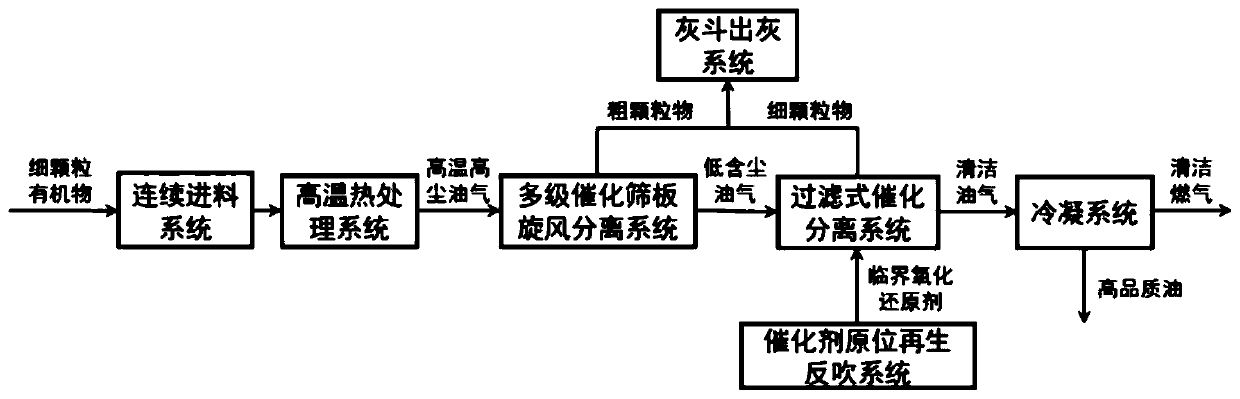

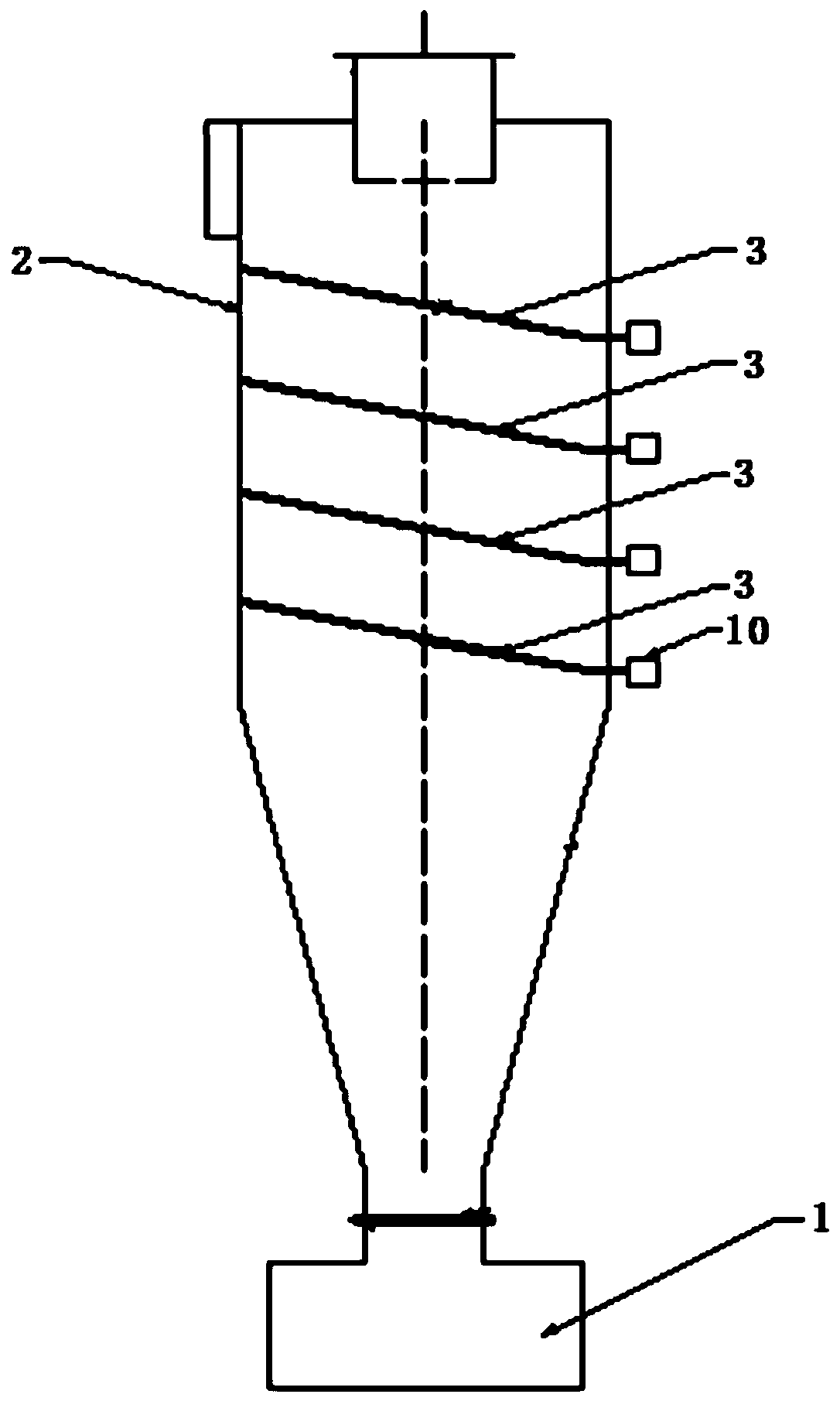

[0052] see figure 1 and figure 2 In the following, the technical scheme of the present invention will be further described in detail by taking the medium-low temperature pyrolysis of low-rank coal as an example. A kind of dedusting method of dusty oil and gas of the present invention, specifically comprises the following steps:

[0053] (1) Low-rank coal is pyrolyzed through the pyrolysis furnace at medium and low temperature to produce pyrolysis oil and gas with high temperature and high dust content at 500-800°C, which enters the third-stage catalytic sieve cyclone separation through the air inlet of the first-stage catalytic sieve cyclone separator The device is used for large particle filtration and preliminary catalysis stage to capture fly ash and dust particles above 5 μm, and at the same time, the macromolecular gas products are converted to small molecular gas products under catalytic conditions, reducing the tar yield and increasing the synthesis gas yield, and obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com