Counting device for punch press

A technology of counting device and punching machine, which is applied in the field of counting devices on punching machines, can solve the problems of miscalculation or missing counting, increase labor intensity, etc., and achieve the effects of improving service life, smooth sliding, and ensuring reliable switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

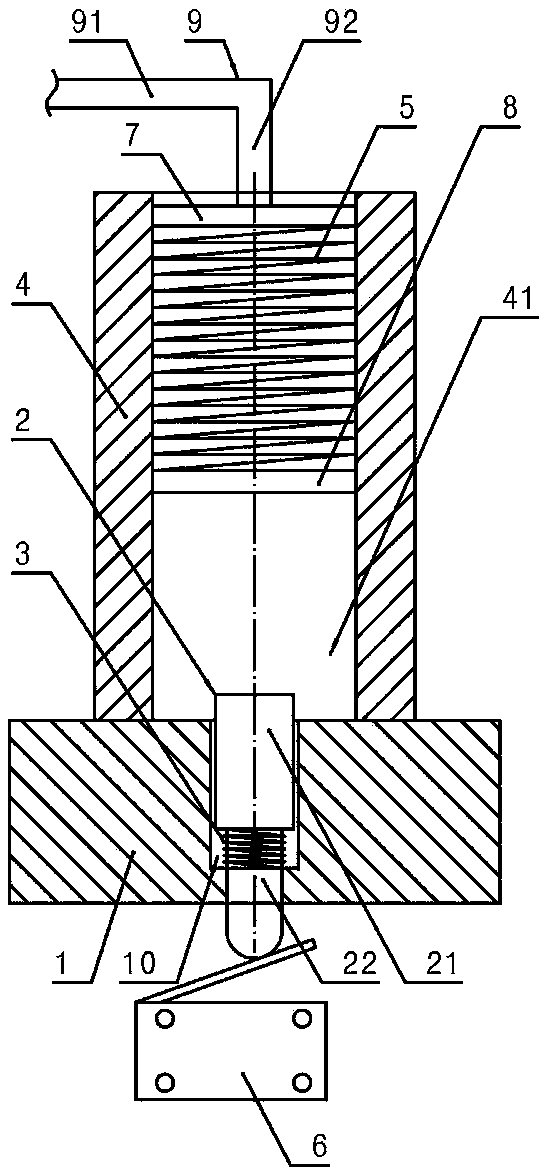

[0012] Such as figure 1 As shown, the counting device used on a punch press according to the present invention includes: a support 1, a guide cylinder 4 is arranged on the support 1, and the upper section is located in the guide cylinder 4 in the support 1, and the upper section is large and the lower section is small, and runs through The stepped hole 10 of the support 1, the centerline of the stepped hole 10 coincides with the centerline of the inner hole 41 of the guide cylinder 4, and the stepped hole 10 is provided with a stepped touch rod 2 with a thick upper section 21 and a thinner section 22, The diameter of the upper section 21 of the trigger rod 2 is larger than the diameter of the lower section of the stepped hole 10, and the micro switch 6 matching with the trigger rod 2 is arranged below the support 1, and the inner hole 41 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com