Welding fixture of automobile control arm mounting support seats

A technology for automotive control arms and mounting supports, which is applied in the direction of manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of stabilizer bar positioning deviation, repair, and unreliable positioning, so as to avoid assembly size deviation and reduce positioning Deviation, Positioning Reliable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

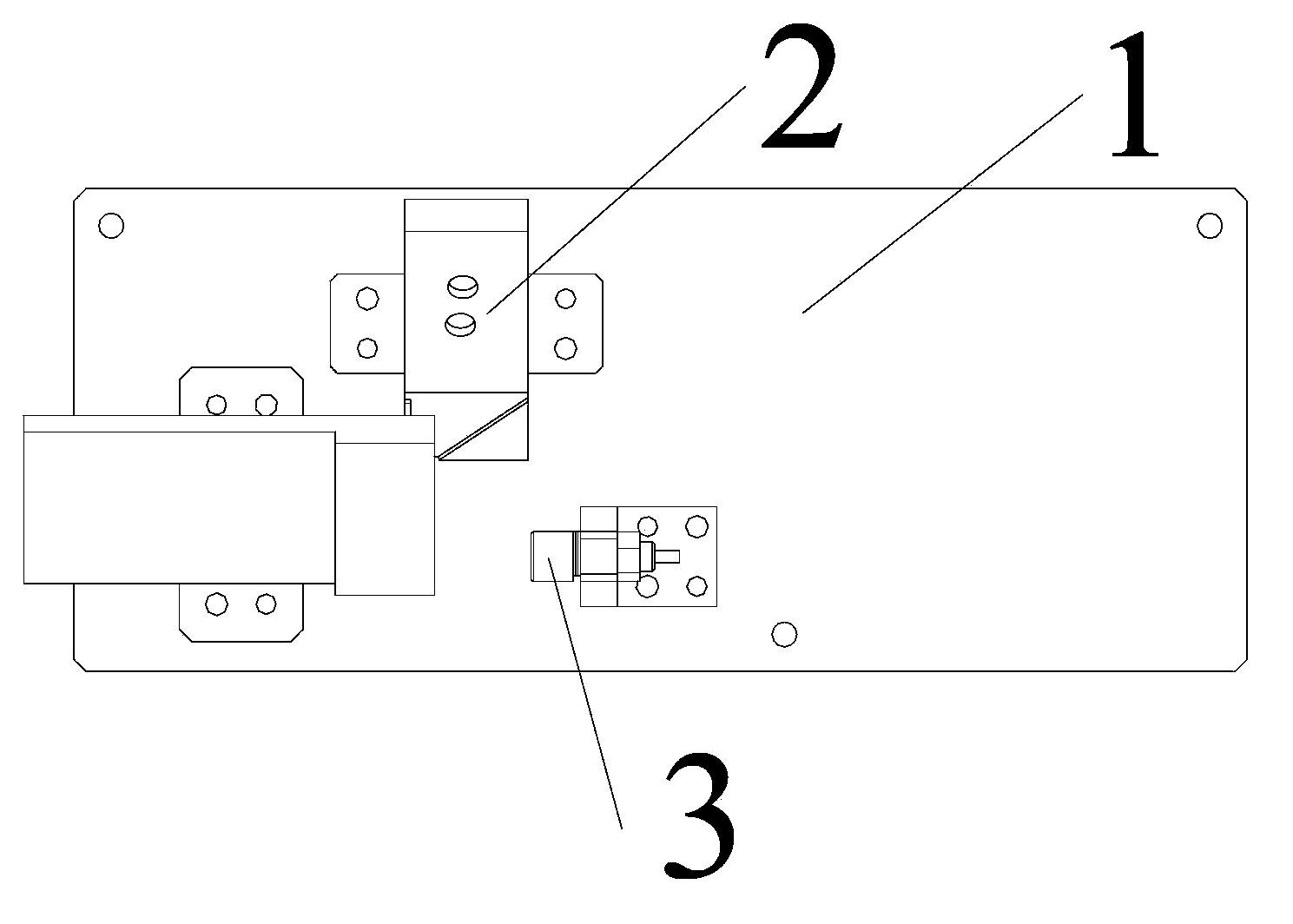

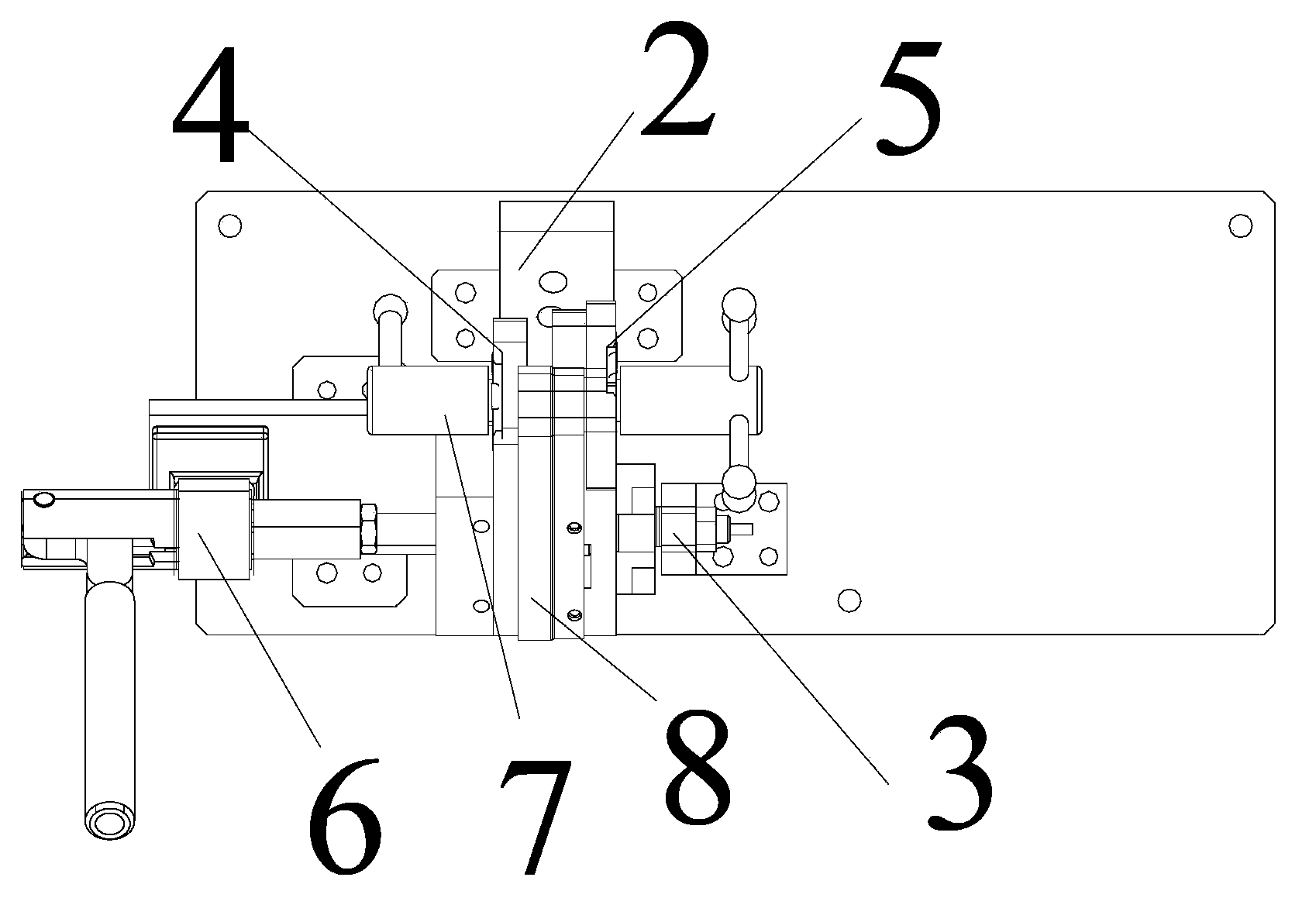

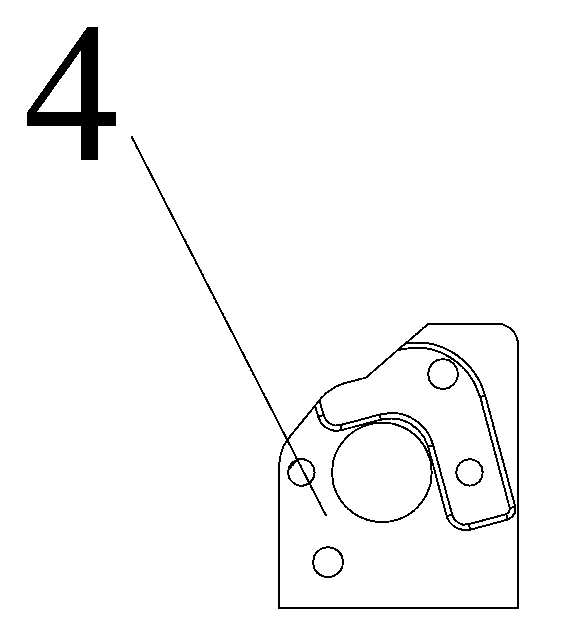

[0014] Such as figure 1 and figure 2 Shown is a welding fixture for the mounting support of an automobile control arm according to the present invention, which includes a rectangular fixture base 1, an error-proof positioning block 2, a limit block 3, an L-shaped follow-up block 4, and a U-shaped follow-up block 5. The push pliers 6 and fastening pin 7, the limit block 3 and the error-proof positioning block 2 are installed on the fixture base 1, and the error-proof positioning block 2 is used to place the control arm mounting support on the fixture base 1 There is a fixing seat for installing the push clamp 6, the limit block 3 and the fixing seat are respectively located on both sides of the error-proof positioning block 2, and the L-shaped follow-up block 4 and the U-shaped follow-up block 5 are installed on the error-proof positioning block 2 And be positioned at the both sides of control arm mounting support, push pliers 6 pushes control arm mounting support to move tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com