Washing machine clamping device

The technology of a clamping device and cleaning machine is applied in the direction of workpiece clamping devices, cleaning methods and appliances, chemical instruments and methods, etc., which can solve problems such as inability to judge and equipment damage, and achieve offset prevention, reasonable structure, and avoidance of damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

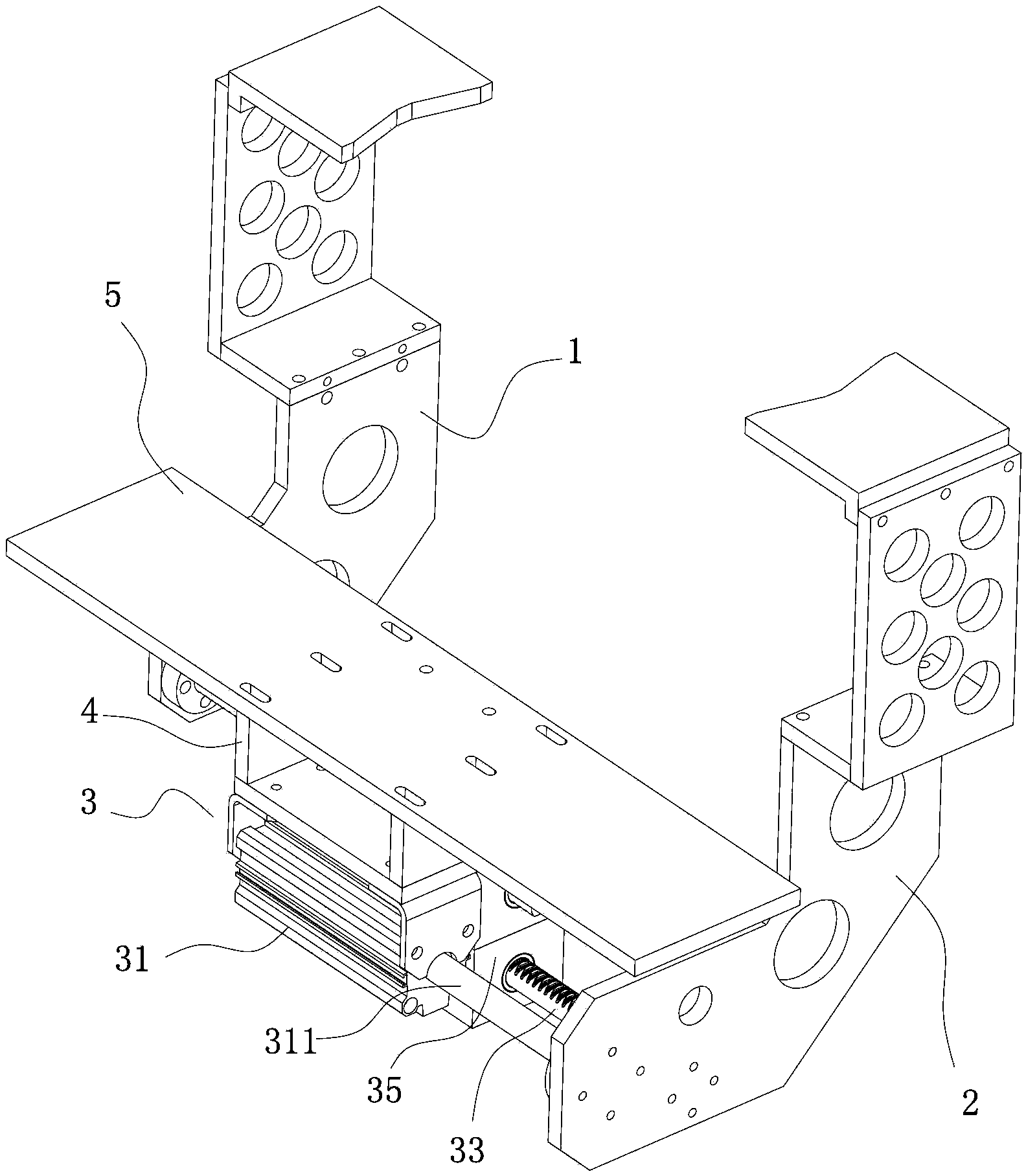

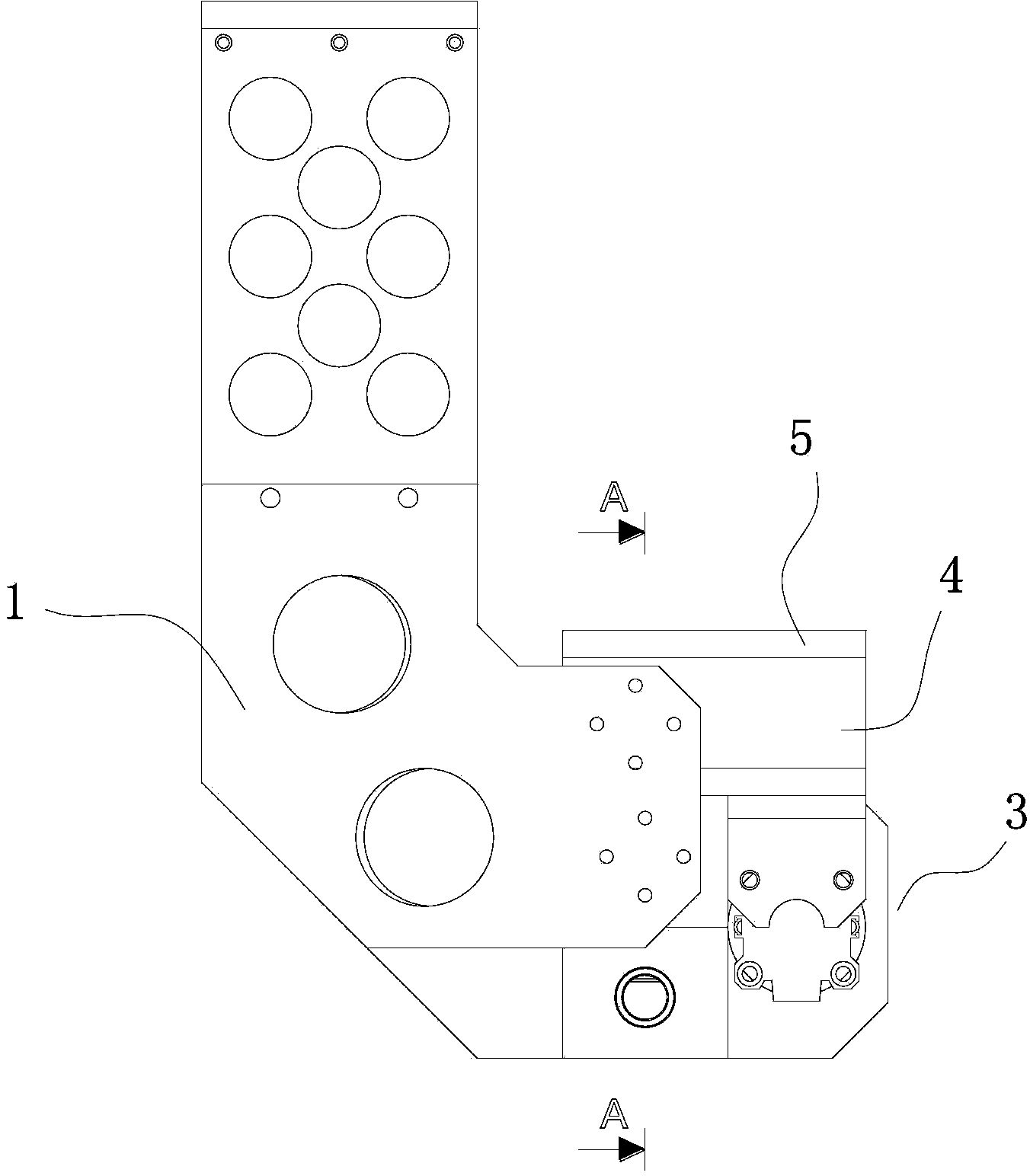

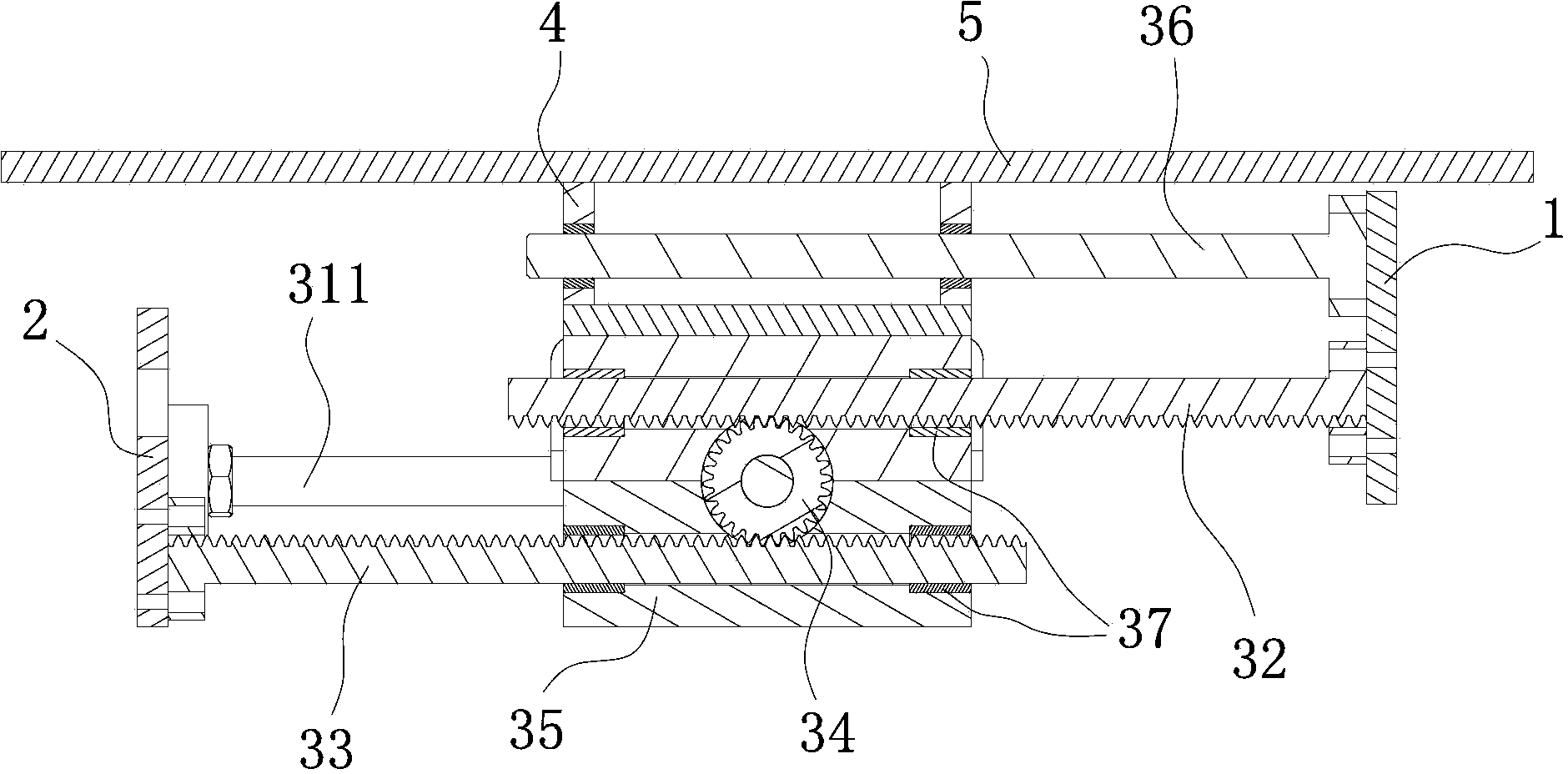

[0014] Example: see Figure 1 to Figure 4 , a cleaning machine clamping device according to the present invention, which includes a left clamp 1 and a right clamp 2 for clamping workpieces to be processed, and an energy-capable clamp is arranged between the left clamp 1 and the right clamp 2 The clamping mechanism 3 that makes the left and right clamping parts 1, 2 simultaneously open or clamp in the linear direction. Described clamping mechanism 3 comprises clamping cylinder 31, left tooth bar 32, right tooth bar 33 and central gear 34, and the length of described left and right tooth bar 32,33 is identical, tooth size is identical and modulus is identical, and the center The gear 34 is located at the center of a housing 35, the left rack 32 is located above the central gear 34 and meshes with the central gear 34, and the right rack 33 is located below the central gear 34 and engages with the central gear. 34, the left end of the left rack 32 is fixedly connected to the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com